7 tuning menu, 8 start sequence, Control panel operating procedures – AERCO KC1000 Low NOx Boiler equipped with C-More 2003 User Manual

Page 27

CONTROL PANEL OPERATING PROCEDURES

3-7

3.7. TUNING

MENU

The Tuning Menu items in Table 3-5 are Factory

set for each individual unit.

Do not change these menu entries unless

specifically requested to do so by Factory-

Trained personnel.

Table 3-5. Tuning Menu

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

Prop Band

1°F

120°F

70°F

Integral Gain

0.00

2.00

1.00

Derivative Time

0.0 min

2.0 min

0.0 min

Reset Defaults?

Yes

No

Are You Sure?

No

3.8. START

SEQUENCE

When the Control Box ON/OFF switch is set to

the ON position, it checks all pre-purge safety

switches to ensure they are closed. These

switches include:

• Safety Shut-Off Valve Proof of Closure

(POC) switch

• Low Water Level switch

• High Water Temperature switch

• High Gas Pressure switch

• Low Gas Pressure switch

If all of the above switches are closed, the

READY

light above the ON/OFF switch will light

and the unit will be in the Standby mode.

When there is a demand for heat, the following

events will occur:

NOTE:

If any of the Pre-Purge safety device switches

are open, the appropriate fault message will be

displayed. Also, the appropriate fault messages

will be displayed throughout the start sequence,

if the required conditions are not observed.

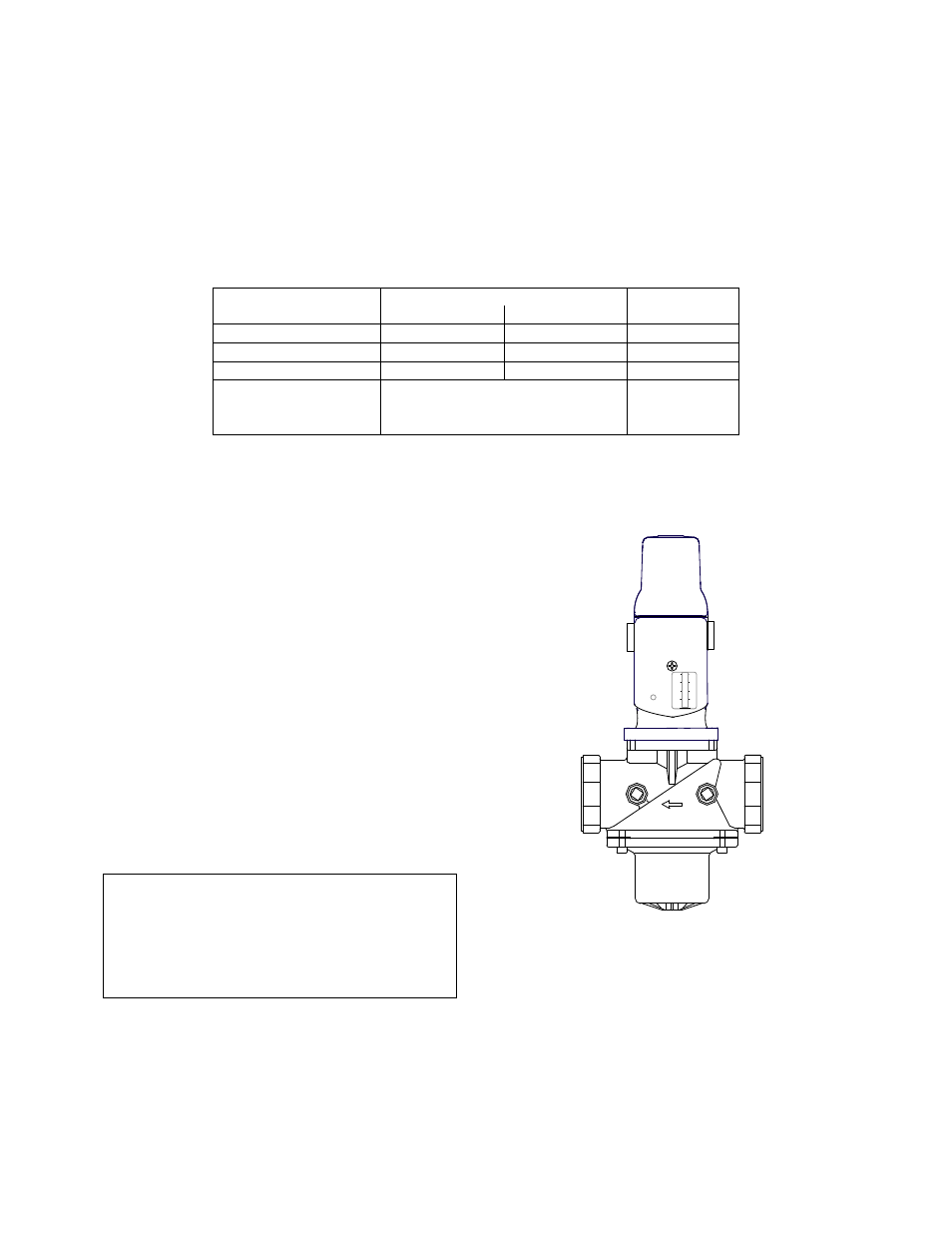

1. The DEMAND LED status indicator will light.

2. The unit checks to ensure that the proof of

closure switch in the Safety Shut-Off Valve

(SSOV) is closed (Figure 3-3).

Figure 3-3.

Safety Shut-Off Valve

3. With all required safety switches closed, a

purge cycle will be initiated and the following

events will occur: