Installation – AERCO KC1000 Low NOx Boiler equipped with C-More 2003 User Manual

Page 19

INSTALLATION

2-11

square inches of free area. The free area must

take into account restrictions such as louvers

and bird screens.

2.10.2 COMBUSTION AIR FROM INSIDE

THE BUILDING

When combustion air is provided from within the

building, it must be supplied through two

permanent openings in an interior wall. Each

opening must have a free area of not less than

one square inch per 1000 BTUH of total input or

1000 square inches of free area. The free area

must take into account any restrictions such as

louvers.

NOTE

KC1000 units equipped with Low NOx

Burners require an optional Cold Air

Damper for operation with Direct Vent/

Sealed Combustion. The Cold Air Damper

is also required when the unit is installed

in an area where the combustion air

supply temperature can drop below 55°F.

Refer to the following paragraph (2.10.3)

and GF-1050 for installation details.

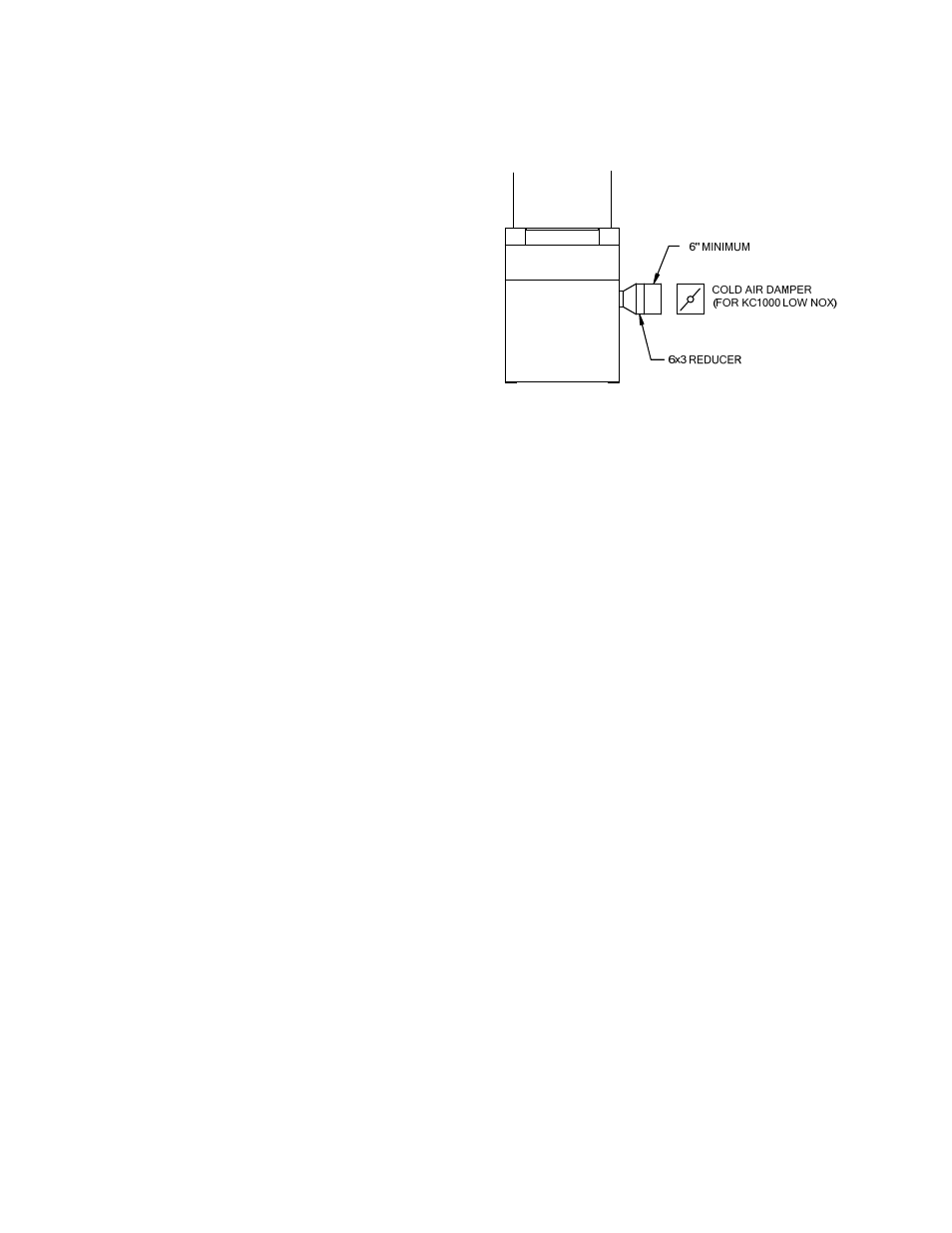

2.10.3 SEALED COMBUSTION

The KC Boiler is UL approved for 100% sealed

combustion application when installed properly.

When a sealed combustion air application is

installed, the sealed combustion air piping must

be deducted from the maximum allowable

discharge piping amounts. Each unit must have

a minimum 6" diameter connection made to the

special Inlet Air Adapter # GP-18917 available

from AERCO. This adapter bolts directly on to

the air inlet of the unit’s blower. See installation

instructions with adapter. All inlet air ducts must

be sealed air tight.

In addition, Cold Air Damper # 99026 must be

installed. It should be located along the inlet duct

run as close as possible to the KC1000 (See

Figure 2.12). The Cold Air Damper must be

placed on individual sections (one Damper per

unit), not in a manifold section. The adjustment

screw on the Damper should be moved to the

center of the slot position and tightened 1/2 turn

past “finger-tight”. DO NOT over-tighten.

See AERCO Venting Guide GF-1050 for further

details.

Figure 2.12

Sealed Combustion Air Connection