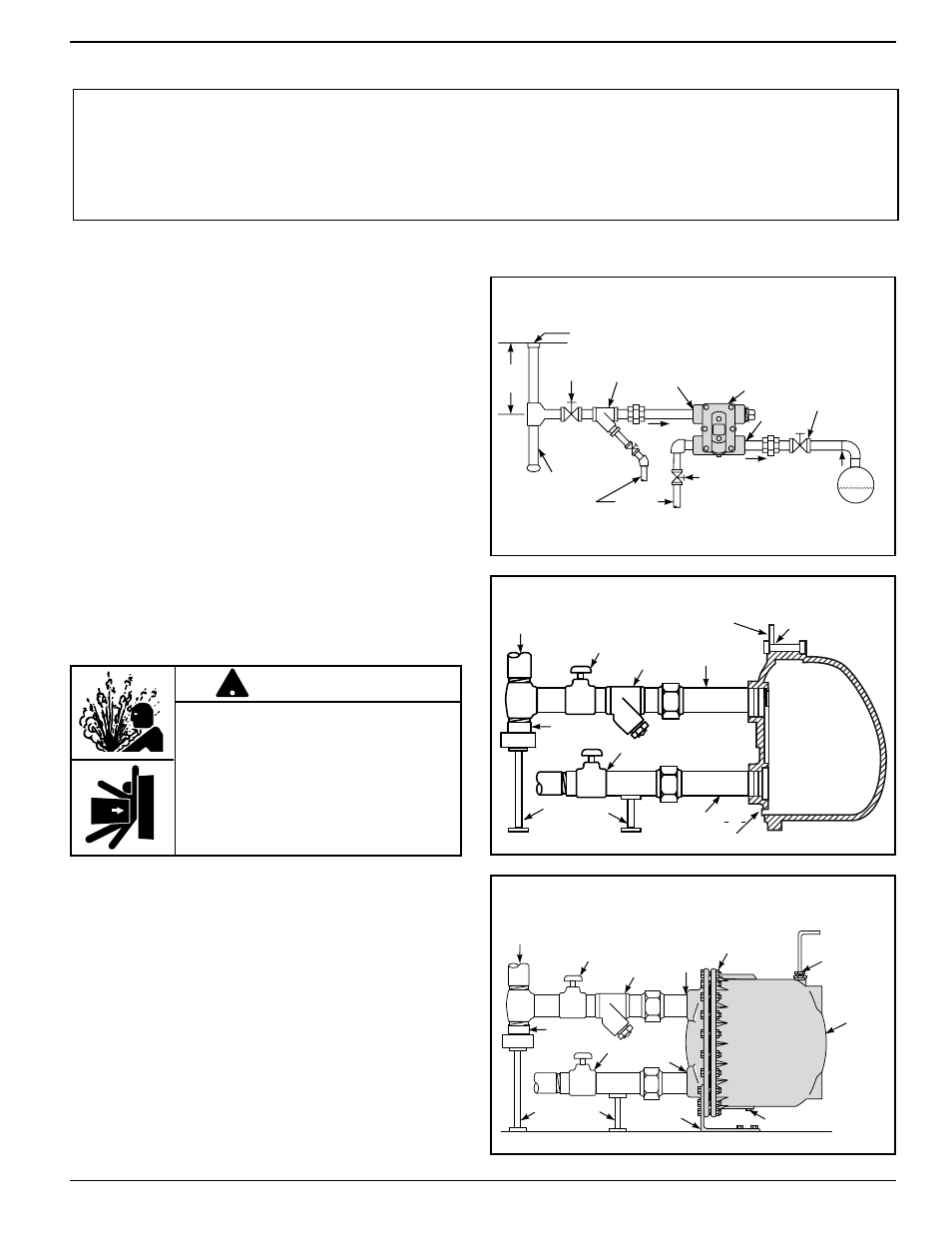

Warning, Step 2, Typical piping diagrams – AERCO Float and Thermostatic Traps Series X User Manual

Page 3: Series c pattern trap installations

Shut-Off

Valve

"Y" Strainer

To Drain

To Return Line

Trap

Gravity Return to

Vented Receiver

Test Valve

Equipment Drain Point

Static

Head

Dirt Pocket

Inlet

Outlet

Shut-Off

Valve

Dirt

Drain Plug

Outlet Valve

Supply

Inlet

Valve

Y Strainer

Cover Bolts

Thermostatic

Vent Pipe to

Gravity Return

Line or Drain

Pipe Supports

Support Foot

Inlet

Outlet

Trap

TYPICAL PIPING DIAGRAMS

Supply

Inlet

Valve

Y Strainer

Cover Bolts

Eye Hook

Dirt

Pipe Supports

Drain Plug

Outlet Valve

Inlet

Outlet

Series H Trap Draining to Gravity Return Line

Series C and X Pattern Trap Installations

2

1

⁄

2

" Series C Pattern Trap Installations

• Install a Hoffman Specialty Y-strainer in the pipe,

ahead of the steam trap. This prevents dirt from

entering the trap.

• Install a blow down valve by connecting it to the

strainer drain plug. This allows the Y-strainer to be

cleaned.

• Install a shut-off valve in the inlet pipe and the outlet

pipe. This allows the trap to be isolated when

servicing.

• Install a test valve in the outlet pipe, and cap it. This

allows the trap to be tested. The cap is used as

safety precaution when the unit is not being tested.

• Blow down the piping using full steam pressure for

(5) five minutes. This cleaning process will remove

debris from the pipe and oil from the system.

Test traps by following the “Troubleshooting” procedure

on page 6.

3

To prevent serious personal injury from

steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a

drain, or stand at least 100 ft. (30m) from

the pipe opening.

Failure to follow this warning could cause

property damage, personal injury, or death.

!

WARNING

STEP 2

IMPORTANT: To prevent system damage from water

hammer or sudden shock, open supply valves slowly.

If you are uncertain about the product’s adaptability

for your application, please call the factory or

authorized representative before using the product.

The trap seat rating (stamped on the nameplate) must

be equal to or greater than the maximum pressure

differential across the trap.