Dampertech_2010 62, Installation instructions – AERCO Belimo AF120-S US Actuator User Manual

Page 8

800-543-9038 USA

866-805-7089 CANADA

203-791-8396 LATIN AMERICA

62

WARNING The wiring technician must be trained and experienced with electronic

circuits. Disconnect power supply before attempting any wiring connections or

changes. Make all connections in accordance with wiring diagrams and follow all

applicable local and national codes. Provide disconnect and overload protection as

required. Use copper, twisted pair, conductors only. If using electrical conduit, the

attachment to the actuator must be made with flexible conduit.

Always read the controller manufacturer's installation literature carefully

before making any connections. Follow all instructions in this literature. If you

have any questions, contact the controller manufacturer and/or Belimo.

Transformers

The AF24 . . actuators require a 24 VAC class 2 transformer and draws a maximum

of 10 VA per actuator. The actuator enclosure cannot be opened in the field, there

are no parts or components to be replaced or repaired.

– EMC directive: 89/336/EEC

– Software class A: Mode of operation type 1

– Low voltage directive: 73/23/EEC

CAUTION: It is good practice to power electronic or digital controllers from a

separate power transformer than that used for actuators or other end devices. The

power supply design in our actuators and other end devices use half wave

rectification. Some controllers use full wave rectification. When these two different

types of power supplies are connected to the same power transformer and the DC

commons are connected together, a short circuit is created across one of the diodes

in the full wave power supply, damaging the controller. Only use a single power

transformer to power the controller and actuator if you know the controller power

supply uses half wave rectification.

Multiple Actuators, One Transformer

Multiple actuators may be powered from one transformer provided the following rules

are followed:

1. The TOTAL current draw of the actuators (VA rating) is less than or equal to the

rating of the transformer.

2. Polarity on the secondary of the transformer is strictly followed. This means that

all No. 1 wires from all actuators are connected to the common leg on the

transformer and all No. 2 wires from all actuators are connected to the hotleg.

Mixing wire No. 1 & 2 on one leg of the transformer will result in erratic operation

or failure of the actuator and/or controls.

Multiple Actuators, Multiple Transformers

Multiple actuators positioned by the same control signal may be powered from

multiple transformers provided the following rules are followed:

1. The transformers are properly sized.

2. All No. 1 wires from all actuators are tied together and tied to the negative leg of

the control signal. See wiring diagram.

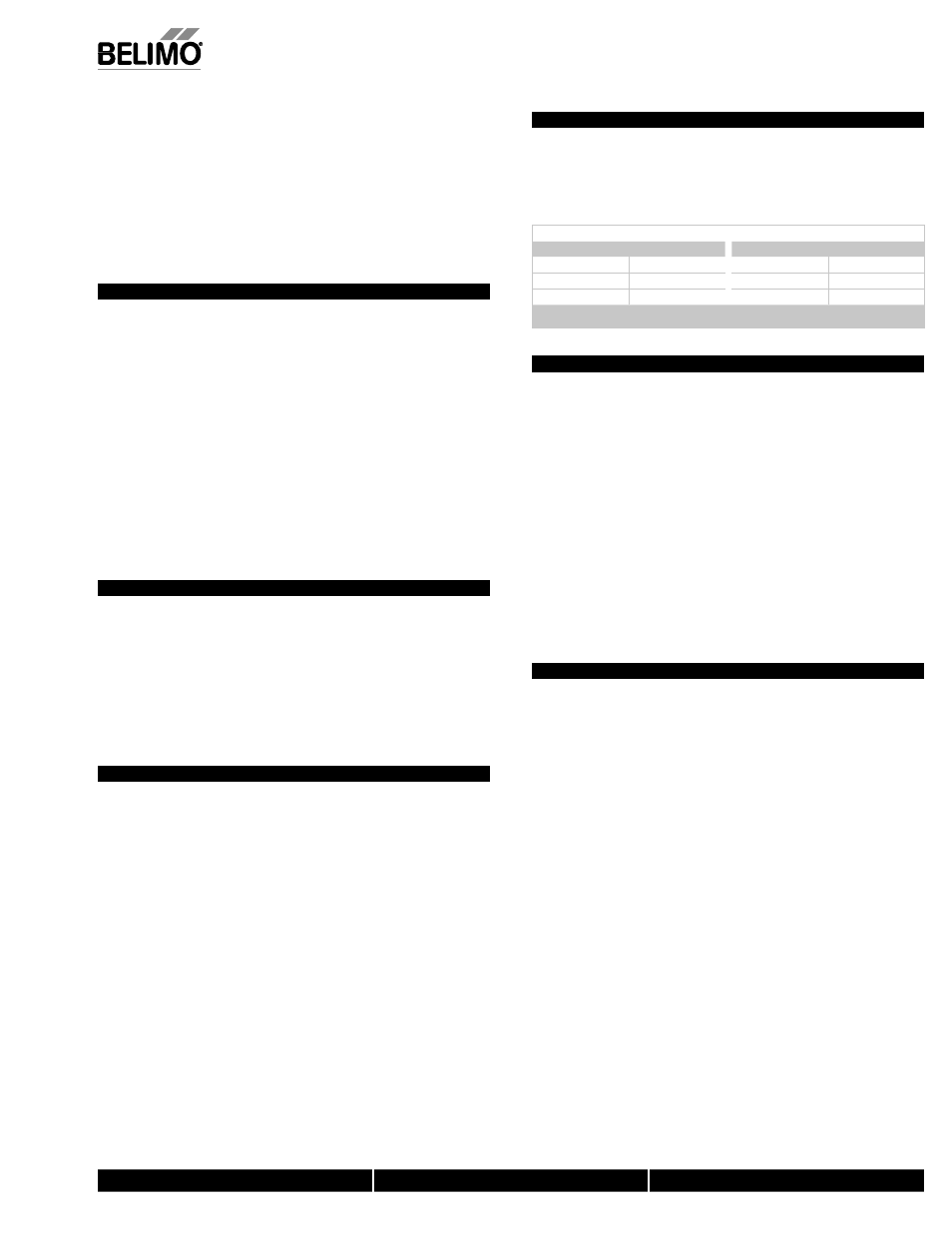

Wire Length for AF... Actuators

Keep power wire runs below the lengths listed in the Figure H. If more than one

actuator is powered from the same wire run, divide the allowable wire length by the

number of actuators to determine the maximum run to any single actuator.

Example:

3 actuators, 16 Ga wire

350 Ft ÷ 3 Actuators = 117 Ft. Maximum wire run

MAXIMUM WIRE LENGTH FOR 10VA

Wire Size

Max. Feet.

Wire Size

Max. Feet

12 Ga

900 Ft.

18 Ga

220 Ft.

14 Ga

550 Ft.

20 Ga

120 Ft.

16 Ga

350 Ft.

22 Ga

60 Ft.

FIGURE H

Wire Type and Wire Installation Tips

For most installations, 18 or 16 Ga. cable works well with the AF24... actuators. Use

code-approved wire nuts, terminal strips or solderless connectors where wires are

joined. It is good practice to run control wires unspliced from the actuator to the

controller. If splices are unavoidable, make sure the splice can be reached for

possible maintenance. Tape and/or wire-tie the splice to reduce the possibility of

the splice being inadvertently pulled apart.

The AF24... proportional actuators have a digital circuit that is designed to ignore

most unwanted input signals (pickup). In some situations the pickup may be severe

enough to cause erratic running of the actuator. For example, a large inductive load

(high voltage AC wires, motors, etc.) running near the power or control wiring may

cause excessive pickup. To solve this problem, make one or more of the following

changes:

1. Run the wire in metallic conduit.

2. Re-route the wiring away from the source of pickup.

3. Use shielded wire (Belden 8760 or equal).

Ground the shield to an earth ground.

Do not connect it to the actuator common.

Initialization of the AF24-SR US

When power is initially applied, the actuator will first release its manual preload

position (This assumes a manual position has been set). The actuator will then rotate

to the full fail-safe position. At this point the microprocessor recognizes that the

actuator is at full fail-safe and uses this position as the base for all of its position

calculations. The microprocessor will retain the initialized zero during short power

failures of up to 20 seconds. For power failures greater than 20 seconds, the actuator

would naturally return to its full fail-safe position prior to the microprocessor losing

its memory. The actuator will also re-initialize if the manual position mechanism is

used.

Installation Instructions

General Wiring Instructions

M40024 - 05/10 - Subject to change.

© Belimo

Aircontrols (USA),

Inc.