AERCO AERClean User Manual

Page 8

Page 8

Benchmark Low NOx Series

AERClean Filtration System Instructions

Doc#

TID-0001-0A

Created: 10/13/2010

Revised: 11/11/2010

Owner: BS-Manager_V.D.

DOC#: TID-0001-0A

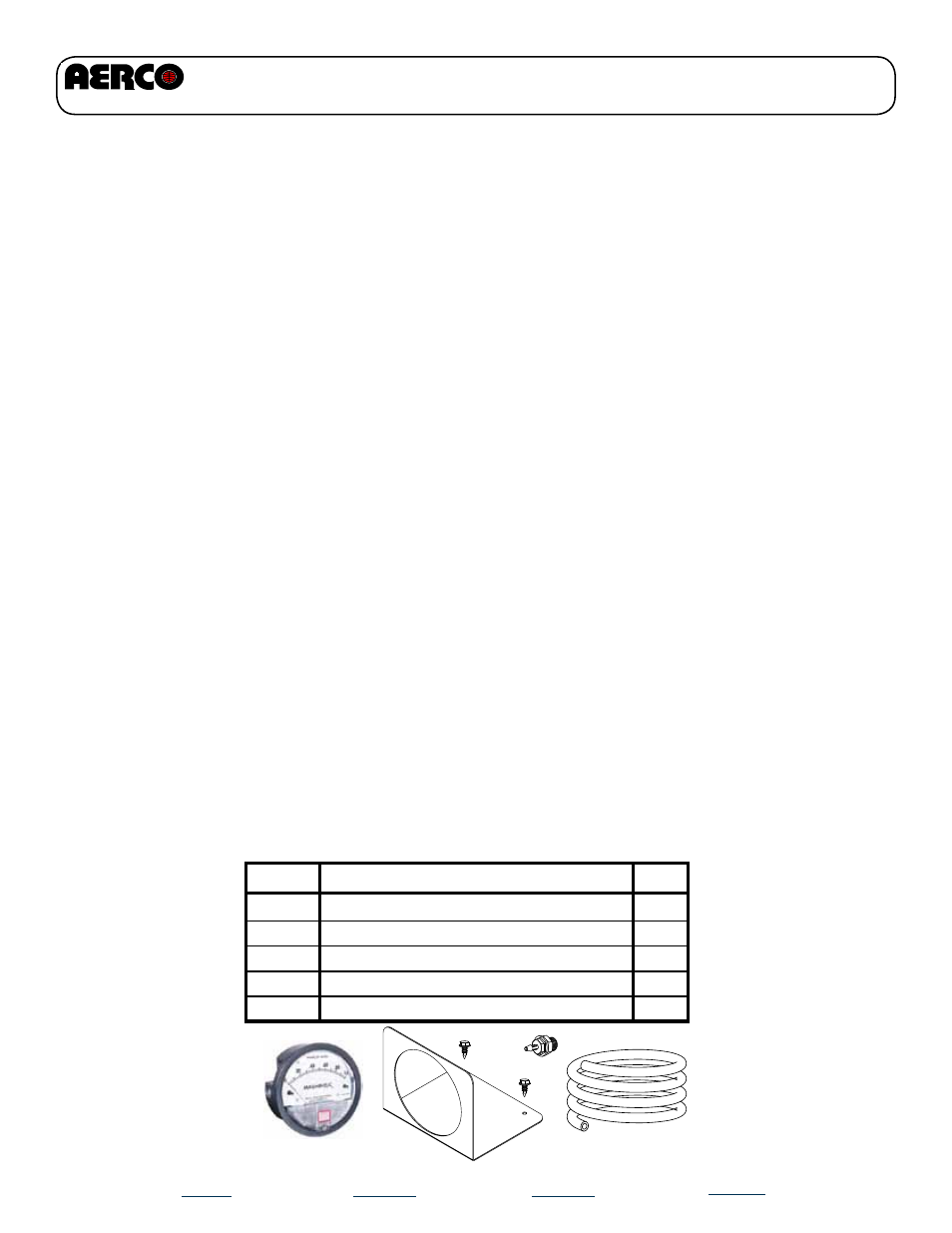

P/N 58032 - Dwyer Magnehelic Differential Pressure Gauge Kit

P/N

67005

91083

97053

33125

Description

Dwyer Magnehelic Diff. Press. Gauge

5/16 O.D., 3/16 I.D. PVC Tubing

3/16” Barbed Fitting

Dwyer Magnehelic mounting Bracket

Qty

1

1

1

1

54010

#10-16 sheet metal screw, 1/2 Long

2

INTRODUCTION

The Magnehelic® gauge is a high accuracy pressure gauge measuring low air or non-corrosive

gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibra-

tion and over-pressures. It is the industry standard to measure fan and blower pressures, filter resis-

tance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems

and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic

valves, and monitors blood and respiratory pressures in medical care equipment.

INSTALLATION

Select a location free from excessive vibration and where the ambient temperature will not exceed

140°F (60°C). Also, avoid direct sunlight which accelerates discoloration of the clear plastic cover.

Sensing lines may be run any necessary distance. Long tubing lengths will not affect accuracy

but will increase response time slightly. Do not restrict lines. If pulsating pressures or vibration

cause excessive pointer oscillation, consult the factory for ways to provide additional damping.

All standard Magnehelic® Differential Pressure Gauges are calibrated with the diaphragm vertical

and should be used in that position for maximum accuracy. If gauges are to be used in other than

vertical position, this should be specified on the order. Many higher range gauges will perform

within tolerance in other positions with only re-zeroing. Low range models of 0.5” w.c. plus 0.25”

w.c. and metric equivalents must be used in the vertical position only.

SURFACE MOUNTING

Locate mounting holes, 120° apart on a 4-1/8” dia. circle. Use No. 6-32 machine screws of appro-

priate length. Provide a 4-9/16” dia. (116 mm) opening in panel. Provide a 4- 3/4” dia. (120 mm)

opening for MP and HP models. Insert gage and secure in place with No. 6-32 machine screws of

appropriate length, with adapters, firmly secured in place.

TO ZERO GAGE AFTER INSTALLATION

Set the indicating pointer exactly on the zero mark, using the external zero adjust screw on the

cover at the bottom. Note that the zero check or adjustment can only be made with the high and

low pressure taps both open to atmosphere.

OPERATION

Negative Pressure: Connect tubing from source of vacuum or negative pressure to either of the

two low pressure ports. Plug the port not used. Vent one or both high pressure ports to atmo-

sphere.