Typical 6 - load point assembly installation, Level requirements, Stiffness – Hardy HI LPRE05 Shear Beams User Manual

Page 17: Level requirements stiffness

OPERATION AND INSTALLATION MANUAL

Page 11

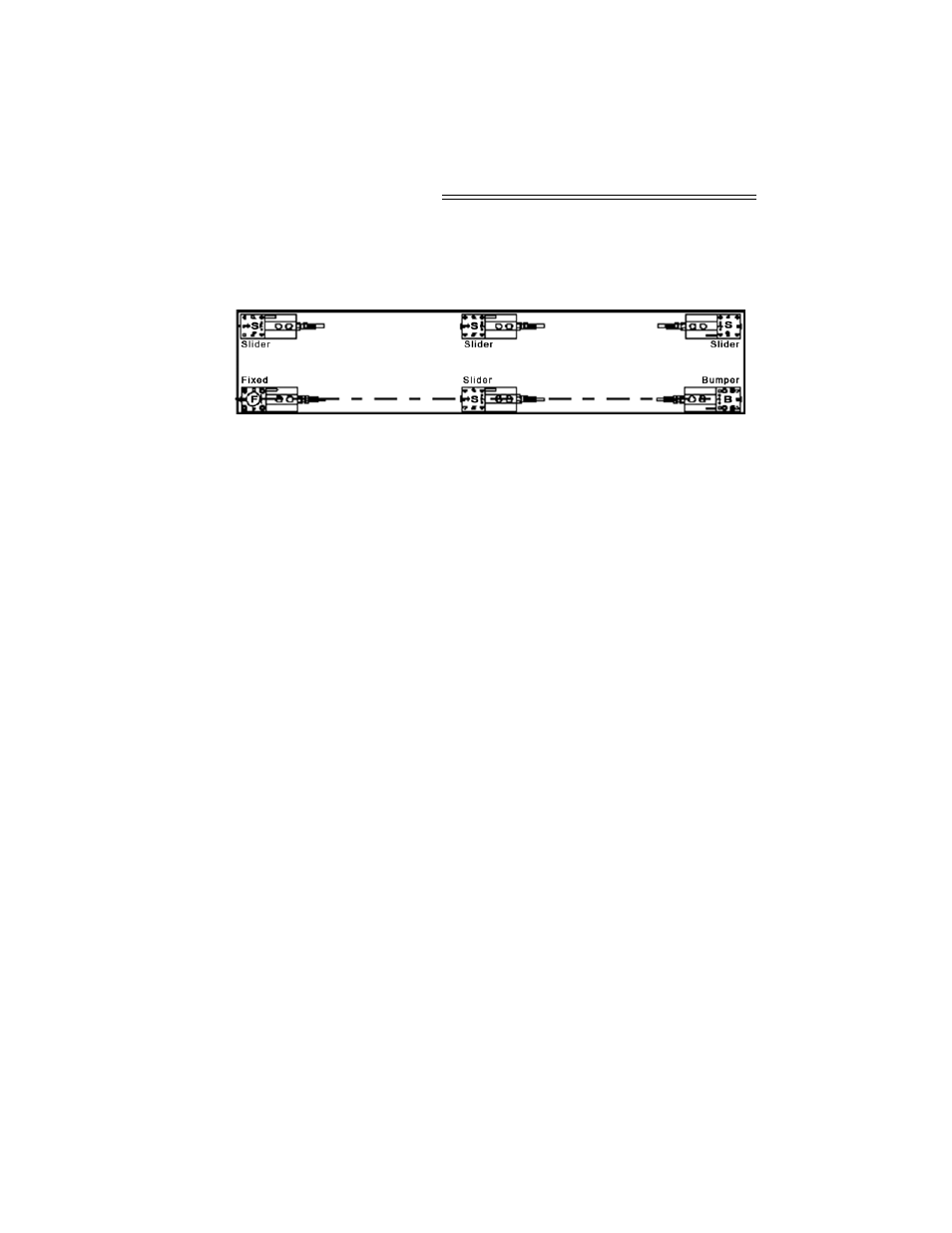

Typical 6 - Load

Point Assembly

Installation

FIG. 14: SIX LOAD CELLS POSITIONED IN A

RECTANGULAR CONFIGURATION

NOTE:

In case there is doubt concerning load point assembly

installation, contact your local Hardy Process Solu-

tions dealer, Application Engineering Department, or

Customer Support Department for assistance.

You can orient the load point assemblies to meet your

system installation requirements. All load point

assemblies can be rotated 360

o

in 90

o

increments. The

examples above are recommendations only.

Level Requirements

For scales that must meet NIST Class 3 (OIML Class

3) specifications:

1.

The base plate support surfaces must be

within 0.2 degrees (0.4mm/100mm)

2.

The top plate support surfaces in the load

carrier must be within 0.5 degrees (0.9mm/

100mm)

For scales with accuracy requirements => 0.1%

1.

The base plate support surfaces must be

within 0.4 degrees (0.08mm/100mm)

2.

Top plate support surfaces in the load carrier

must be within 1 degree (1.8mm/100mm)

Stiffness

Load variations and external forces can cause support

surface level variations.