Carrier AQUAZONE 50PEC09-18 User Manual

Page 46

46

produce water (or debris) velocities that can erode the heat ex-

changer wall and ultimately produce leaks.

Proper water treatment can minimize tube fouling and

pitting. If such conditions are anticipated, water treatment anal-

ysis is recommended. Refer to the Carrier System Design Man-

ual, Part 5, for general water conditioning information.

Clean condensers with an inhibited hydrochloric acid solu-

tion. The acid can stain hands and clothing, damage concrete,

and, without inhibitor, damage steel. Cover surroundings to

guard against splashing. Vapors from vent pipe are not harmful,

but take care to prevent liquid from being carried over by the

gases.

Warm solution acts faster, but cold solution is just as effec-

tive if applied for a longer period.

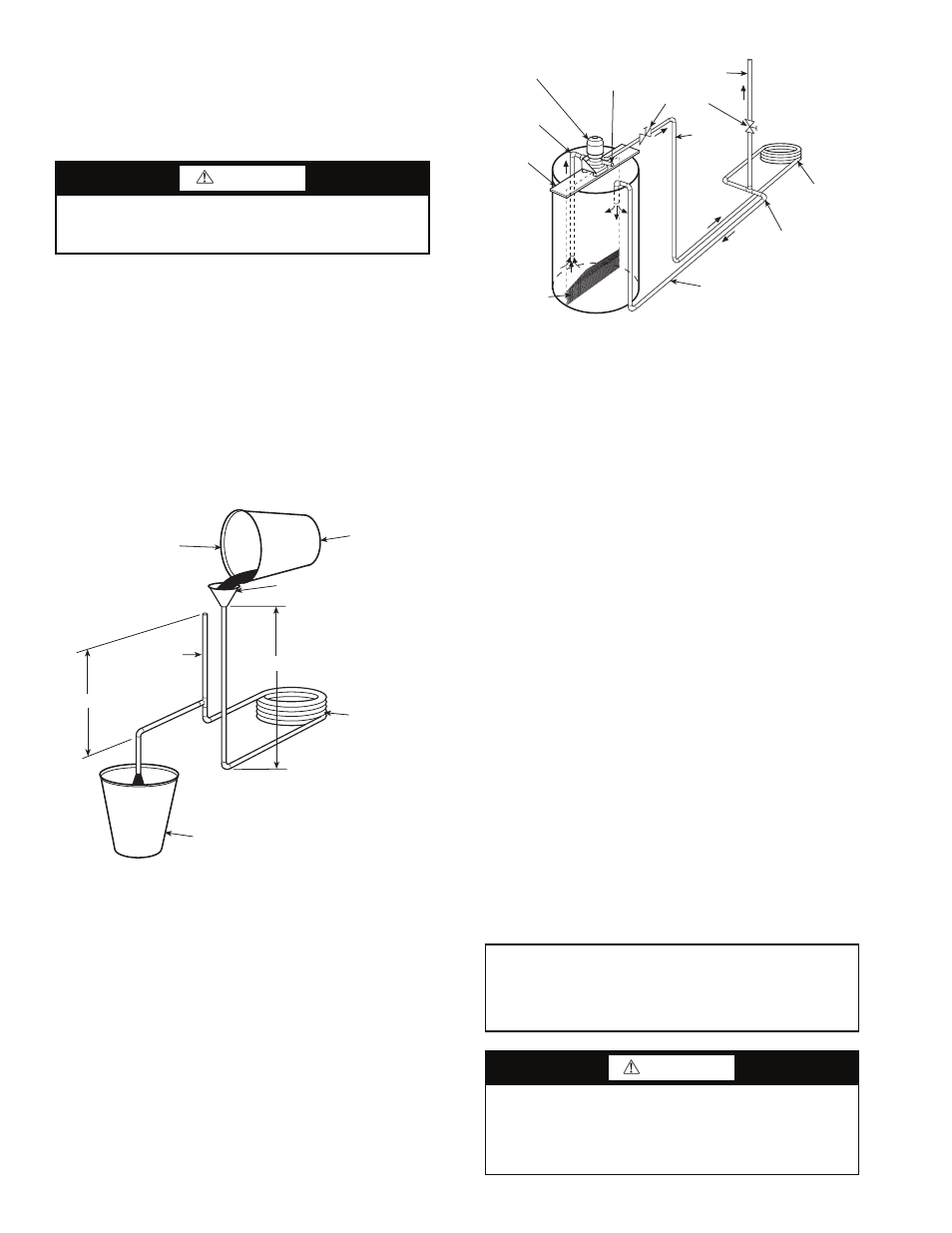

GRAVITY FLOW METHOD — Do not add solution faster

than vent can exhaust the generated gases.

When condenser is full, allow solution to remain overnight,

then drain condenser and flush with clean water. Follow acid

manufacturer’s instructions. See Fig. 37.

FORCED CIRCULATION METHOD — Fully open vent

pipe when filling condenser. The vent may be closed when

condenser is full and pump is operating. See Fig. 38.

Regulate flow to condenser with a supply line valve. If

pump is a nonoverloading type, the valve may be fully closed

while pump is running.

For average scale deposit, allow solution to remain in con-

denser overnight. For heavy scale deposit, allow 24 hours.

Drain condenser and flush with clean water. Follow acid manu-

facturer’s instructions.

Condensate Pans —

Check condensate drain pans for

algae growth every three months. If algae growth is apparent,

consult a water treatment specialist for proper chemical treat-

ment. The application of an algaecide every three months will

typically eliminate algae problems in most locations. Check

condensate hose for leaks and blockage and correct any

problems.

Blower Motors —

All units have lubricated fan motors.

BLOWER MOTORS SHOULD NEVER BE LUBRICATED

UNLESS OBVIOUS, DRY OPERATION IS SUSPECTED.

Periodic maintenance oiling is not recommended because it

will result in dirt accumulating on excess oil and cause eventu-

al motor failure. Conduct annual dry operation check and am-

perage check to ensure amp draw is no more than 10% greater

than that indicated by serial plate data.

Compressor —

Conduct an amperage check annually on

the compressor and fan motor. Amperage draw should not

exceed normal full load amps. Maintain a log of amperage to

detect deterioration prior to component failure.

Safety Control Reset —

The 50PEC heat pumps are

furnished with high-pressure, low-pressure and low-

temperature cutouts to prevent the machine from operating at

abnormal conditions of temperature or water flow.

The contacts of the high-pressure control used on 50PEC

units are designed to open at 376 psig and automatically

re-close at 304 psig. The Complete C or Deluxe D control

monitors this and other functions such as refrigerant tempera-

tures and pressures and condensate overflow and will interrupt

unit heating or cooling operation.

The machine must be reset manually. Reset is accomplished

by pressing the STOP button and then pushing either HI HEAT,

LOW HEAT, HI COOL or LO COOL to restart the unit in the

desired mode of operation. (The 50PEC unit can also be reset

by opening and closing the supply power disconnect switch.)

CAUTION

Follow all safety codes. Wear safety glasses and rubber

gloves when using inhibited hydrochloric acid solution.

Observe and follow acid manufacturer’s instructions.

IMPORTANT: If the unit must be reset more than twice,

check the unit for a dirty filter, abnormal entering water

temperature, inadequate or excessive water flow, and inter-

nal malfunctions. If the unit continues to cut out, contact a

trained service technician.

WARNING

When replacing the compressor contactor or lockout relay

in a unit with electromechanical controls, use only Carrier

factory authorized parts. Substitution of other components

may result in an inoperative safety circuit and may cause a

hazardous condition.

SUCTION

PUMP

SUPPORT

TANK

FINE MESH

SCREEN

RETURN

GAS VENT

PUMP

PRIMING

CONN.

GLOBE

VALVES

SUPPLY

1” PIPE

CONDENSER

REMOVE WATER

REGULATING VALVE

Fig. 38 — Forced Circulation Method

FILL CONDENSER WITH

CLEANING SOLUTION. DO

NOT ADD SOLUTION

MORE RAPIDLY THAN

VENT CAN EXHAUST

GASES CAUSED BY

CHEMICAL ACTION.

PAIL

FUNNEL

CONDENSER

PAIL

3’ TO 4’

VENT

PIPE

5’ APPROX

1”

PIPE

Fig. 37 — Gravity Flow Method