System checkout, Caution – Carrier AQUAZONE 50PEC09-18 User Manual

Page 34

34

8. Refill the system with clean, chemically treated water.

Since water varies for each locality, contact a local water

treatment company for the correct treatment chemicals to

use in the area. Set the boiler to raise the loop temperature

to approximately 85 F.

.

Circulate the solution for a minimum of 8 to 24 hours. At

the end of this period, shut off the circulating pump and

drain the solution. Repeat system cleaning as necessary.

9. When the cleaning process is complete, remove the short-

circuited hoses. Connect the hoses to the proper supply

and return connections on each unit. Refill the system and

bleed off all air.

10. Test the system pH with litmus paper. The system water

should be slightly alkaline (pH 7.0 to 8.5). Add chemi-

cals, as appropriate, to maintain acidity levels.

11. When the system is successfully cleaned, flushed, refilled

and bled, check the main system panels, safety cutouts

and alarms. Set the controls to properly maintain loop

temperatures.

System Checkout —

When the installation is complete

and the system is cleaned and flushed, follow the system

checkout procedure outlined below.

1. Voltage: Ensure voltage is within the utilization range

specifications of the unit compressor and fan motor.

2. System Water Temperature: Ensure temperature is within

an acceptable range shown in Table 8. (When conducting

this check, also verify proper heating and cooling set

points.)

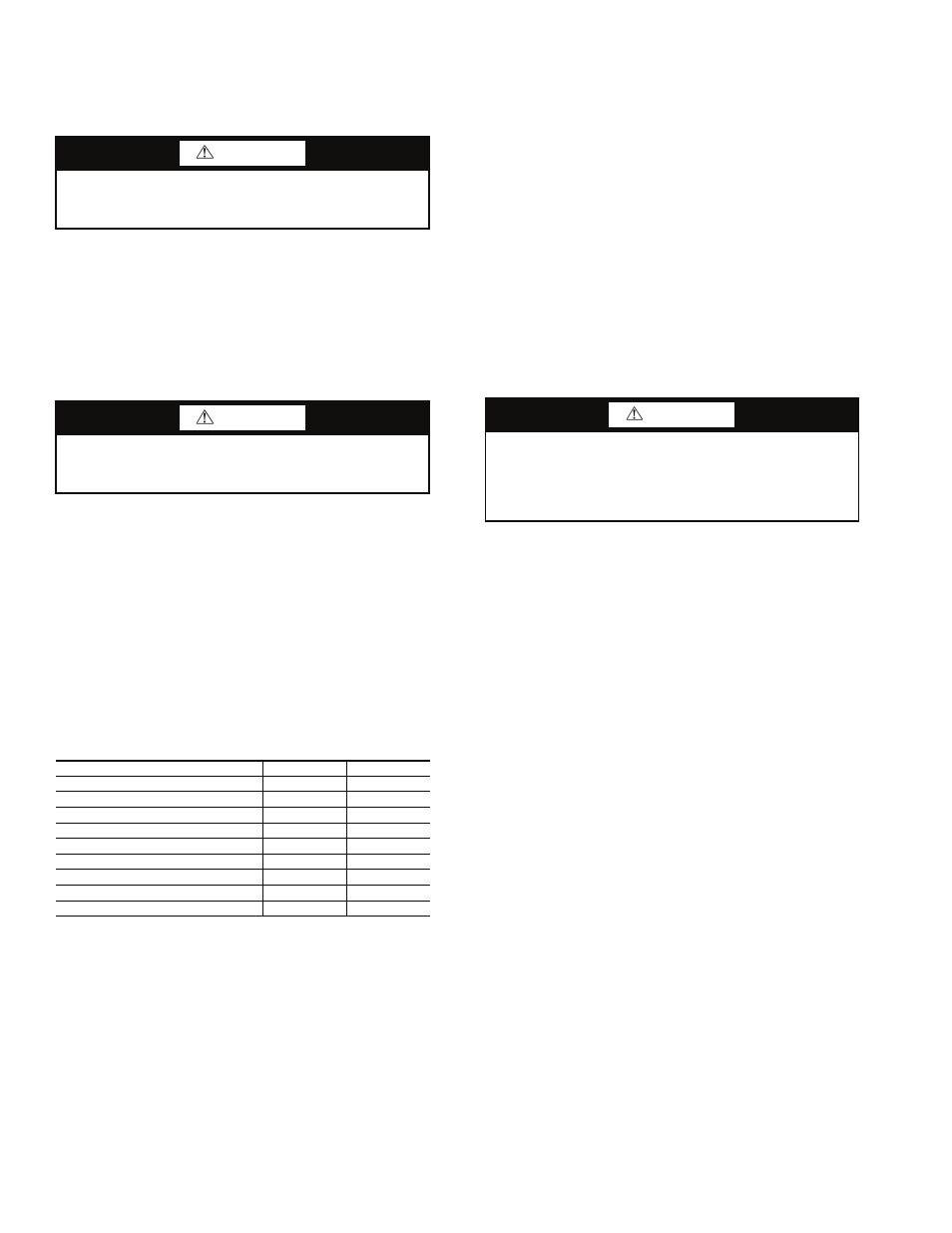

Table 8 — Air and Water Limits

NOTES:

1. Minimum air and water conditions can only be used at nominal flow rates.

2. 50PEC units may have up to two values at maximum or minimum with all

other parameters at normal conditions.

3. Operating limits shown are for start-up, not continuous operation. It is

assumed that such a start-up is for the purpose of bringing the space to

desired occupancy temperature.

3. System Water pH: Verify system water is slightly alkaline

(pH = 7.5 to 8.5). Proper pH promotes the longevity of

the hoses and heat exchangers. See Table 9.

4. Closed-Type Cooling Tower (Open Tower with Heat Ex-

changer): Check equipment for proper temperature set

points and operation.

5. Balanced Water Flow Rate to Heat Pump: Record the

inlet and outlet water temperatures as each heat pump

unit is started. This check will eliminate nuisance unit

tripouts resulting from water velocities that are either too

low or too high; it can also prevent erosive water flow

rates.

6. Standby Pump: Verify the standby pump is properly in-

stalled and in operating condition.

7. System Control: To ensure no catastrophic system fail-

ures occur, verify system controls are functioning and the

sequencing is correct.

8. Freeze Protection for Water Systems: Verify freeze

protection is provided for the outdoor portion of the loop

water system. Inadequate freeze protection leads to

expensive repairs.

9. System Water Loop: Verify all air is bled from the sys-

tem. Air in the system impedes unit operation and causes

corrosion in the system piping.

10. Unit Filters: To avoid system damage and to provide

maximum performance, ensure the unit filter is clean.

11. Unit Fans: Manually rotate fans to assure free rotation.

Ensure fans are properly secured to the fan shaft. Do not

oil fan motors on start-up since they are lubricated at the

factory.

12. System Control Center: To ensure control of the tempera-

ture set points for operation of the system’s heat rejector

and boiler, examine the system control and alarm panel

for proper installation and operation.

CAUTION

To avoid possible damage to piping systems constructed of

plastic piping DO NOT allow loop temperature to exceed

110 F.

CAUTION

DO NOT use “Stop-Leak” or any similar chemical agent in

this system. Addition of these chemicals to the loop water

will foul the system and will inhibit unit operation.

50PEC UNIT

COOLING (F)

HEATING (F)

Min Ambient Air

50

50

Rated Ambient Air

80

70

Max Ambient Air

100

85

Min Entering Air

50

50

Rated Entering Air, dry bulb/wet bulb

80/67

70

Max Entering Air, dry bulb/wet bulb

100/83

80

Min Entering Water

30

20

Normal Entering Water

85

70

Max Entering Water

110

90

CAUTION

To avoid equipment damage, DO NOT leave system filled

in a building without heat during the winter unless anti-

freeze is added to system water. Condenser coils never

fully drain by themselves and will freeze unless winterized

with antifreeze.