10 repairs, 1 checklist for troubleshooting, Repairs 10.1 checklist for troubleshooting – FRITSCH PULVERISETTE 13 classic line User Manual

Page 38: Repairs

10

Repairs

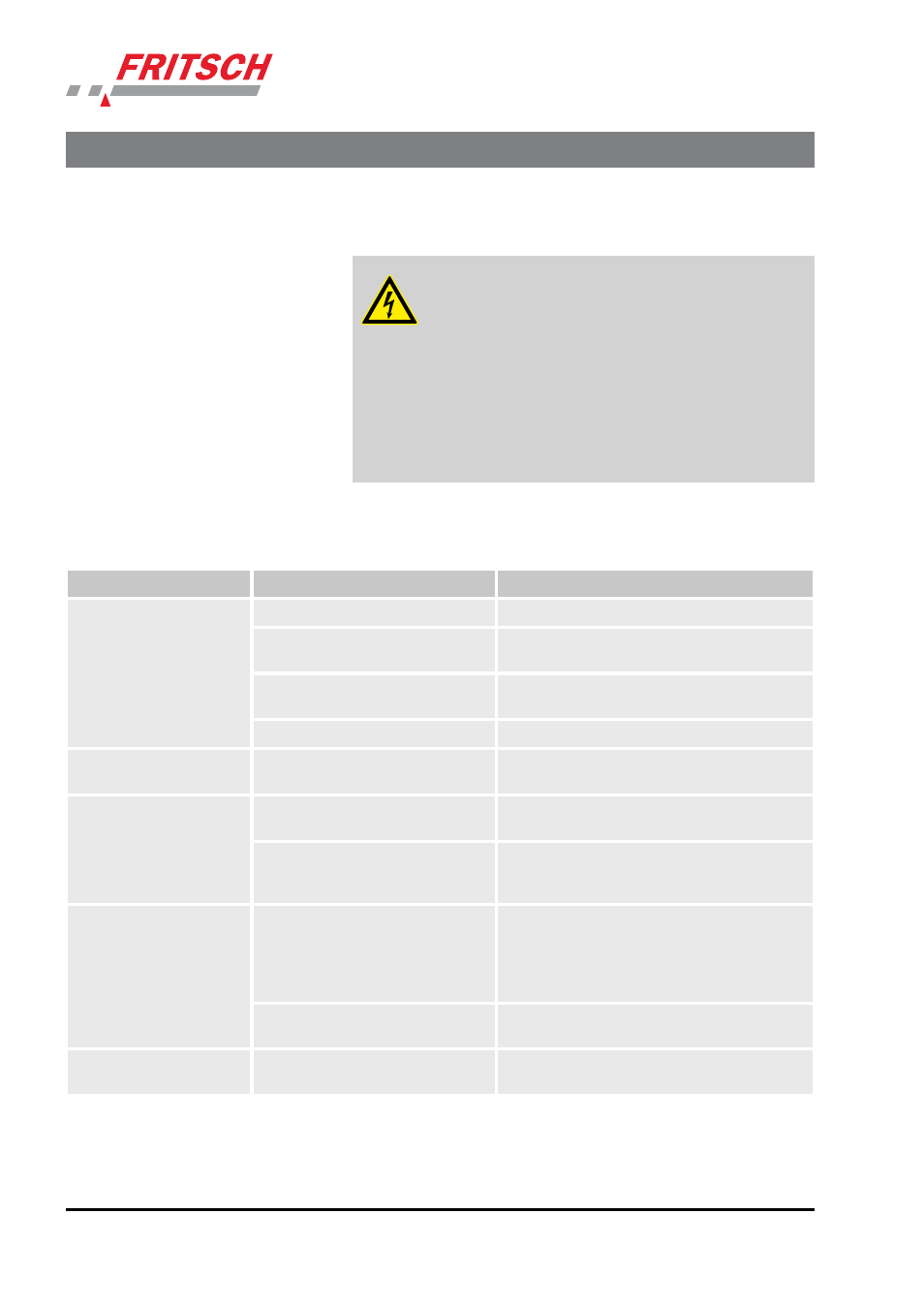

DANGER!

Mains voltage!

– Before beginning with repair work, unplug the mains

plug and protect the device against being unintention-

ally switched back on.

– Indicate repair work with warning signs.

– Repair work may only be performed by specialised per-

sonnel.

– Put safety equipment back into operation after mainte-

nance work.

10.1 Checklist for troubleshooting

Fault description

Cause

Remedy

Mill does not start up

No mains connection

Plug in mains plug

Grinding chamber safety switch is

open

Close the grinding chamber properly

Grinding stock container safety

switch open

Insert the grinding stock container properly

Overload of the motor

Allow motor protection switch to cool down

Grinding disks are not

rotating

Grinding disks are touching (gap

width < 0.1 mm)

Set gap width or stop screw, see Ä Chapter 6.1

‘Setting the minimum gap width’ on page 22

Mill stops running during

operation

Overload! Switching off by motor

protection switch

Allow the mill to cool down, reduce sample

addition

Grinding chamber overfilled, jam-

ming of grinding stock that is too

large/hard

Open grinding chamber and empty

Mill has poor grinding

result

Grinding disks worn down

Reverse direction of rotation or replace grinding

disk. See Ä Chapter 9.3 ‘Exchanging the

grinding disks’ on page 34 and Ä Chapter 9.2

‘Rotation direction of the drive motor’

Grinding disks not parallel

Remove grinding disks, clean holder and rein-

sert

Grinding stock escapes

Grinding chamber or grinding stock

container seals is soiled or defective

Clean or replace seals

Repairs

- 38 -