1 gear oil exchange, Maintenance – FRITSCH PULVERISETTE 13 classic line User Manual

Page 32

Functional part

Task

Test

Maintenance interval

Protection switch 1 (acti-

vated by closing the

grinding chamber)

Start-up block

Grinding chamber open:

Mill does not start!

Caution!

If the switch is defective,

the disks will start up. Do

not reach into the mill

while it is running.

Before each use (replace

defective switch)

Protection switch 2 (acti-

vated by closing the

grinding stock container)

Start-up block

Grinding stock container

not inserted: Mill does not

start up!

Caution!

If the switch is defective

the mill will start up. Do

not reach into the mill

while it is running.

Before each use (replace

defective switch)

Grinding disk gap width

Break function

Test distance

The gap must be at least

0.1 mm.

Before each use

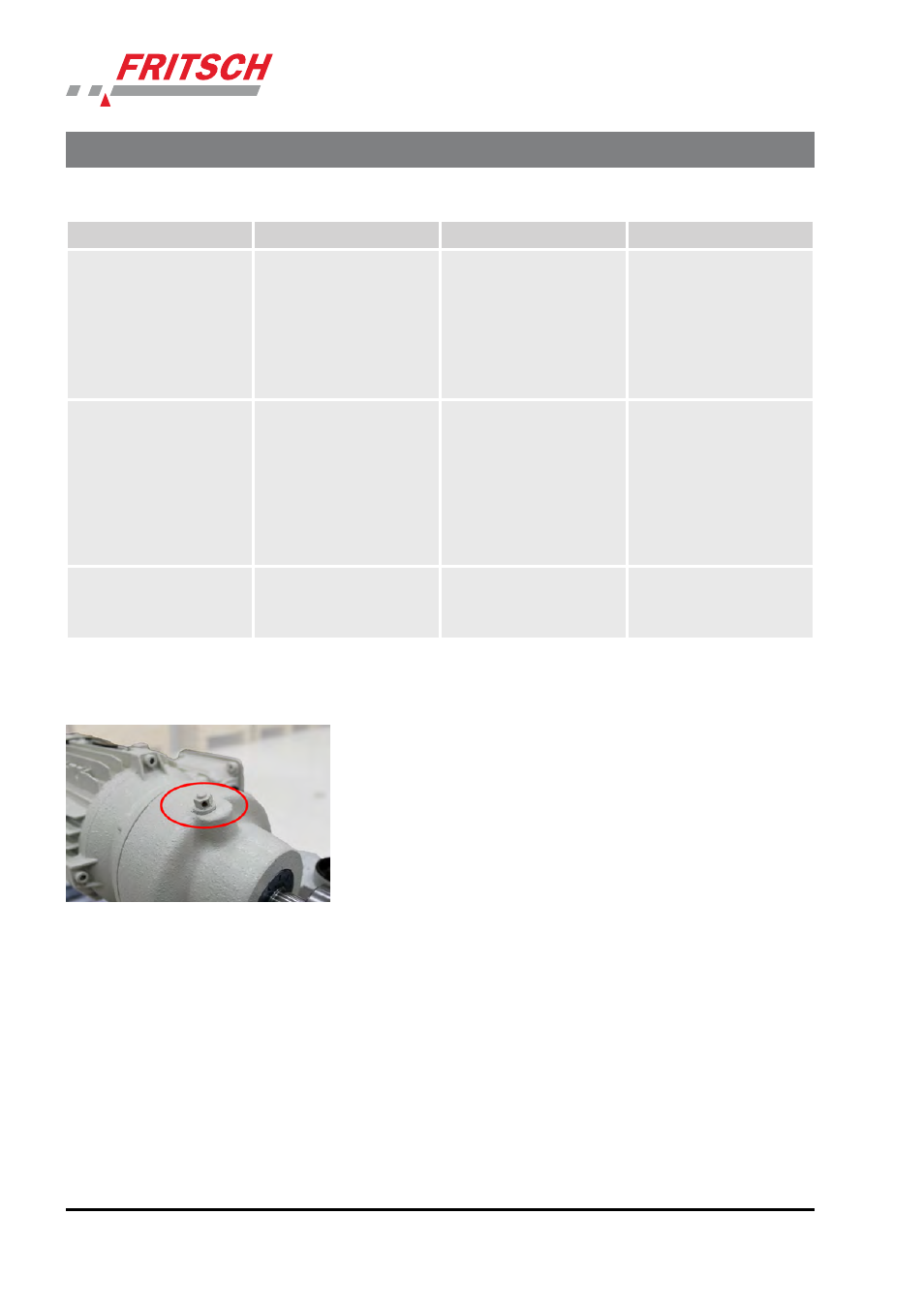

9.1 Gear oil exchange

The gears of the motor are filled with gear oil at delivery (ISO VG 220

Ord. no.: 85.0110.00). To change the gear oil, there is an unscrewable

filler screw at the top of the gear housing.

The oil needs to be changed after approx. 5 years.

Maintenance

- 32 -