1 exchanging the fixed grinding disks, Maintenance – FRITSCH PULVERISETTE 13 classic line User Manual

Page 35

CAUTION!

Clean the holder and the back of the disks thoroughly

before installing the new disks. This is very important in

particular when employing the ZrO

2

and WC+Co disks, so

that the disks are seated without tension and parallel to

each other.

When using the ZrO

2

grinding disks:

When tightening the screws, it is important that the tight-

ening torque is not too great (see table) and is the same for

both screws.

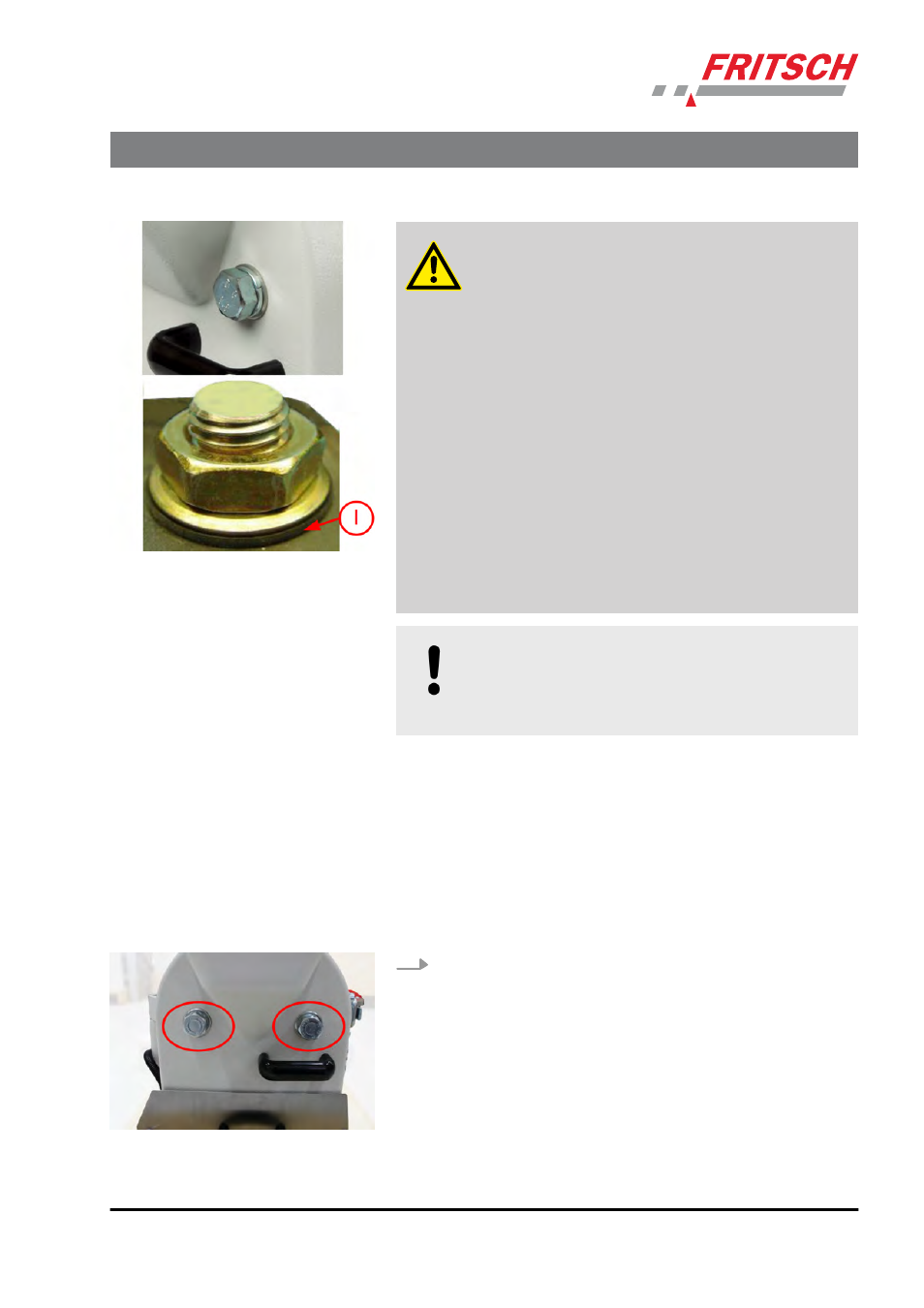

The ZrO

2

grinding disks come with rubber washers (l) that

are placed under the steel washers. The nuts are then tight-

ened until the rubber washer is slightly squeezed out by the

steel washer. This ensures a tightening torque of approx. 20

Nm.

All other grinding disks (as pictured above) are fastened

with two hexagon screws M20 x 35 and with a washer and

a spring ring.

NOTICE!

Hold the grinding disks firmly during the exchange and do

not drop them. This can cause disks made of zirconium

oxide to break or splinter.

The grinding disks wear down after a certain time, depending on the

material being crushed. Check the surfaces at regular intervals. For

changing the direction of rotation or exchanging the disks, observe the

information in Ä Chapter 9.2 ‘Rotation direction of the drive motor’

on page 34 and as follows in Ä Chapter 9.3.1 ‘Exchanging the fixed

grinding disks’ on page 35 as well as Ä Chapter 9.3.2 ‘Exchanging the

movable grinding disks’ on page 36.

9.3.1 Exchanging the fixed grinding disks

1.

Loosen the fastening screws (fastening nuts for ZrO

2

) with a 30

mm spanner before opening the grinding chamber.

Maintenance

- 35 -