Checkline BLH User Manual

Page 4

Checkline-Europe

-4-

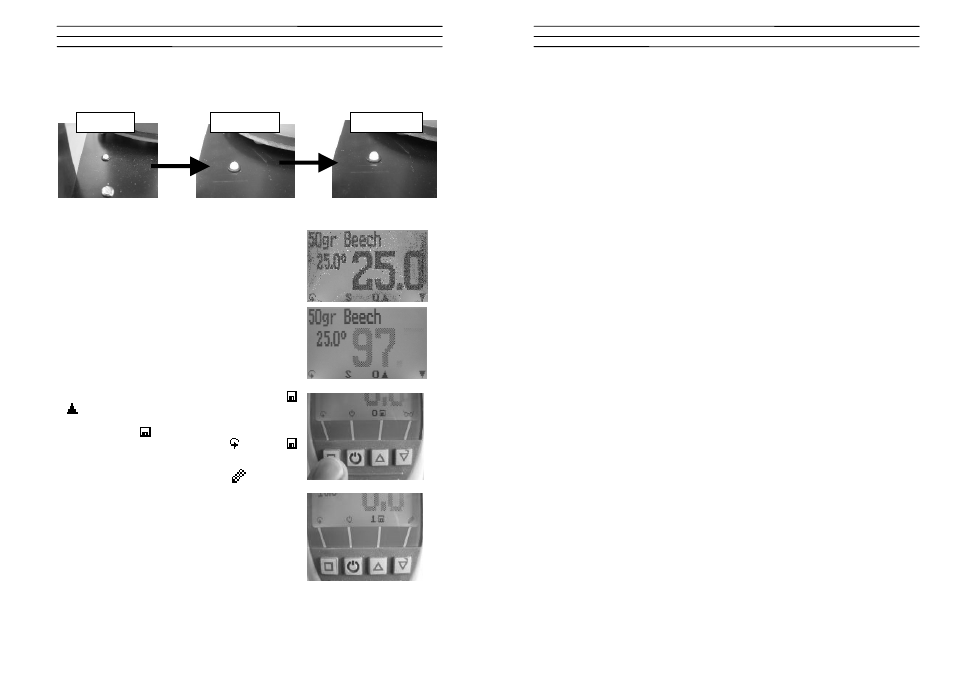

6. Compress the material in the measuring chamber now by turning the hand

wheel (1 turn per second) until the LED turns green. Now slowly (0.5 turns per

second) must be rotated until the LED flashes orange once.

7. Then immediately press the start button on the

device

8. After a few seconds, the display shows stable

water content.

9. The water content of the sample is now visible on

the display.

10. If the measure value is blinking, the valid

measuring range is exceeded (limits see list on

page 5). In this case the accuracy will be

decreasing.

11. To save the results in the save menu press the

(

button).

The

storage

was successful when the number in front of the

symbol

increased.

To

reach the store menu please press (

) until the

appears.

12. To name the saved results press the

button.

13. Empty the humimeter BLH and ensure that no

material rests are accumulated in the measuring

chamber.

LED off

LED green

LED orange

Checkline-Europe

-13-

13.0 MOST COMMON REASONS FOR MISS READINGS

•

Product temperature out of application range

Material below 0°C resp. above +40°C (32 to 104 °F) may cause faulty

measurements. The storage of cold material in a warm storage area usually

creates condensed water which may lead to major measuring errors.

•

Not adjusted material under test

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A very high temperature

difference has a negative effect on the stability of the measurement results.

•

Wrong calibration curve

Before you measure your sample, double check the correct selection of the

calibration curve.

•

Wrong filling quantity

Fill in exactly the right weight of wood chips in the measuring chamber.

•

Wet or moldy material

•

Frozen measuring material

•

The steel plate which is mounted on the spindle part has to be cleaned at

regular intervals. As well as the pressure pin on the base plate (use a dry cloth

or something like that). Specifically, after measurement of wet material can be

located on the disk. This material can interfere with the following measurements!

•

Compression function has to be done smoothly

To compress the hand wheel approximately one turn per second should be

rotated. When the green LED is on, the hand wheel has to be turned a half turn

further per second until the LED is orange is on.