Checkline DT-5TS User Manual

Page 13

13

Setting Examples

MODE -01- (RPM or Rate Measurement)

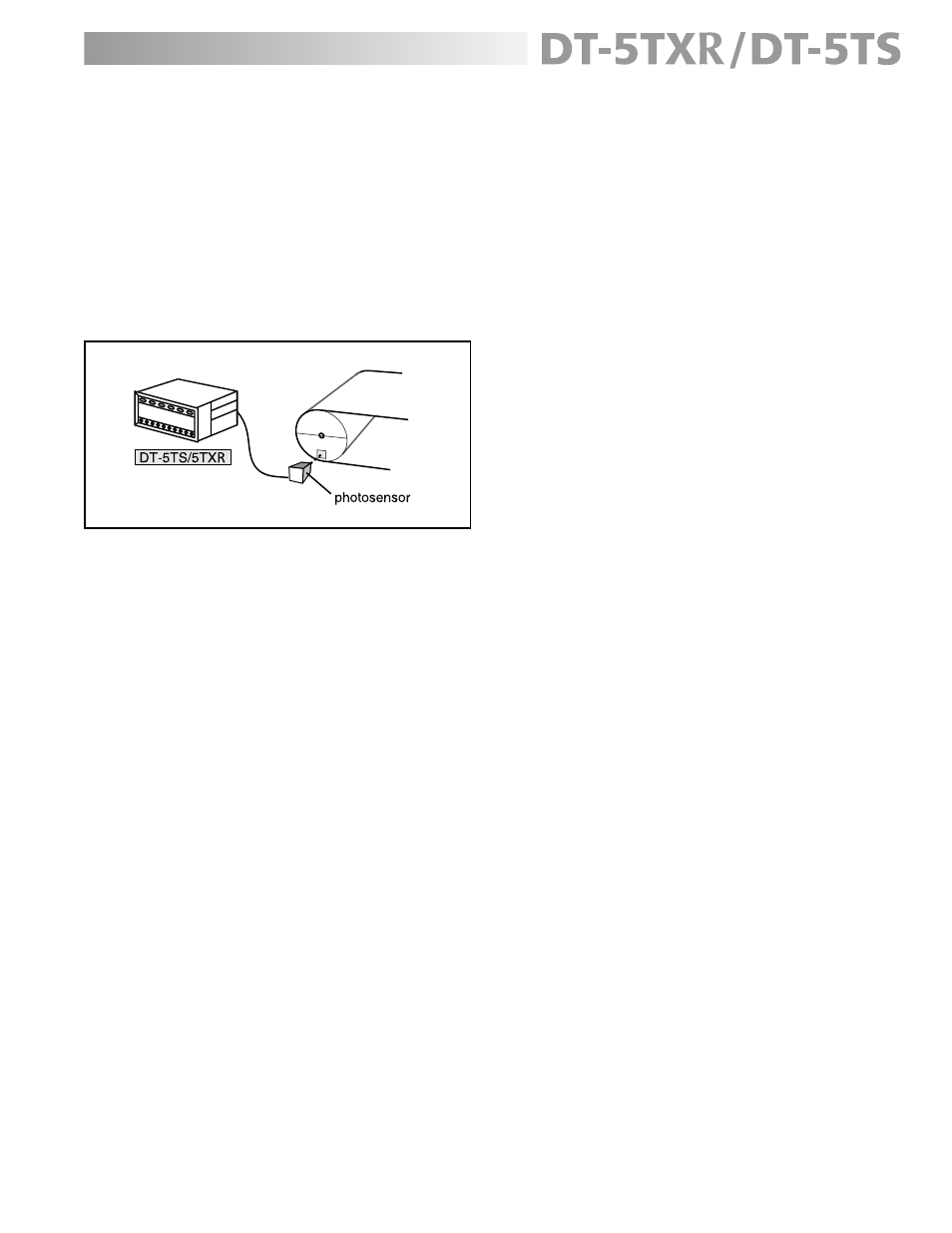

The DT-5TXR/5TS units are fully scalable, which means that

RPM can be used to display linear speed in many units,

i.e. ft/m, yd/m, m/m, in/m etc. Please use the following

example as a guide for programming this feature.

Suppose a motor drives a roller through a speed reducer

and the speed of the roller is 100 RPM when the speed

of the motor is 1,700 RPM (due to load, in this case the

roller). The roller feeds a belt that carries material from

point A to point B and we want to monitor the speed of

the belt in ft/m at all times.

The following are known: (refer to the mode -01-

parameters table on the bottom of page 7)

a)

Parameter 1 = 1 p/r (one marker on the face of the

roller)

b) Parameter 2 = 100 RPM (due to speed reducer)

c)

Parameter 3 = ? (ft/m)

Parameter 3 is calculated by determining the

circumference of the roller and multiplying by the RPM

(parameter 2). The circumference can be determined by

multiplying π times the diameter (C=πD). The diameter

must be measured in whatever unit needs to be

monitored. Because ft/m needs to be monitored, the

diameter needs to be measured in feet. If it is assumed

that the roller is one foot in diameter (D=1) and

π

=3.14159, then the circumference would have to be

3.14159 ft. This number would then be multiplied by

100 (parameter 2) to arrive at 314.159 ft/m, parameter 3.

Now:

a)

Parameter 1 = 1 p/r

b) Parameter 2 = 100 RPM

c)

Parameter 3 = 314.159 ft/m

After these parameters have been programmed (see

page 8) , feet per minute will be displayed and will

fluctuate with the changing RPM.

For example: if the RPM drops to 50, then the display

will show 157.079 ft/m.

In the example given, parameters 4, 5 and 6 needed no

change; these are adjusted according to operator

preference.

D

Parameter 4 is selectable and is used when there is a

steady increase/decrease in speed and the operator wants

to observe the changes (in this case higher update times

are selected) or if the speed changes rapidly within certain

limits (this may bother the observer) a lower update time

is selected.

Parameter 5 is set according to how quickly the operator

wants to see the display go to “0” after the sensor stops

producing an output.

Set parameter 6 according to the sensor being used.

MODE -02-

As stated in the previous example, the DT-5TXR/DT-5TS

units are fully scalable. This is true for not only rate

measurement but also time measurement. The following

is an elapsed time measurement/monitoring example.

The elapsed time for curing a product in a commercial

oven is critical and must be monitored. From the oven’s

specifications it is possible to discover either the velocity

(speed) that the conveyor moves product or the amount

of time that the product has to be in the oven.

NOTE:

If neither of these can be found, simply use a hand

held tachometer to measure the conveyor belt speed.

From either one of the above methods the 5m-long oven

is determined to have a belt speed of 2.8m/m. In this

example a rotary pulse generator is being used that is

moving at 1,200 RPM and generating 60 pulses per

revolution. Therefore the following facts are known:

a)

The length of the oven is 5 meters

b) The speed of the pulse generator is 1,200 RPM

(parameter 2)

c)

The p/r of the pulse generator is 60 pulses

(parameter 1)

d) The belt speed is 2.8 m/m

Use the formula t=d/v, to determine the amount of time

that the product will spend in the oven (parameter 3).

Dividing 5 (length of oven) by 2.8 (speed of oven

conveyor) equals 1.786 min (107 seconds or 1 min and

47 seconds) , parameter 3 (see page 9 for programming).

Parameters 4 and 5 should be set to the operator’s

preference. Set parameter 6 according to the sensor

being used.

Now the unit will display time as it relates to the RPM.

For example, if the RPM falls to 600, the display will show

214 seconds.