Checkline DTMB User Manual

Page 8

8

5.00 SETUP

5.10 Installing/Replacing Batteries

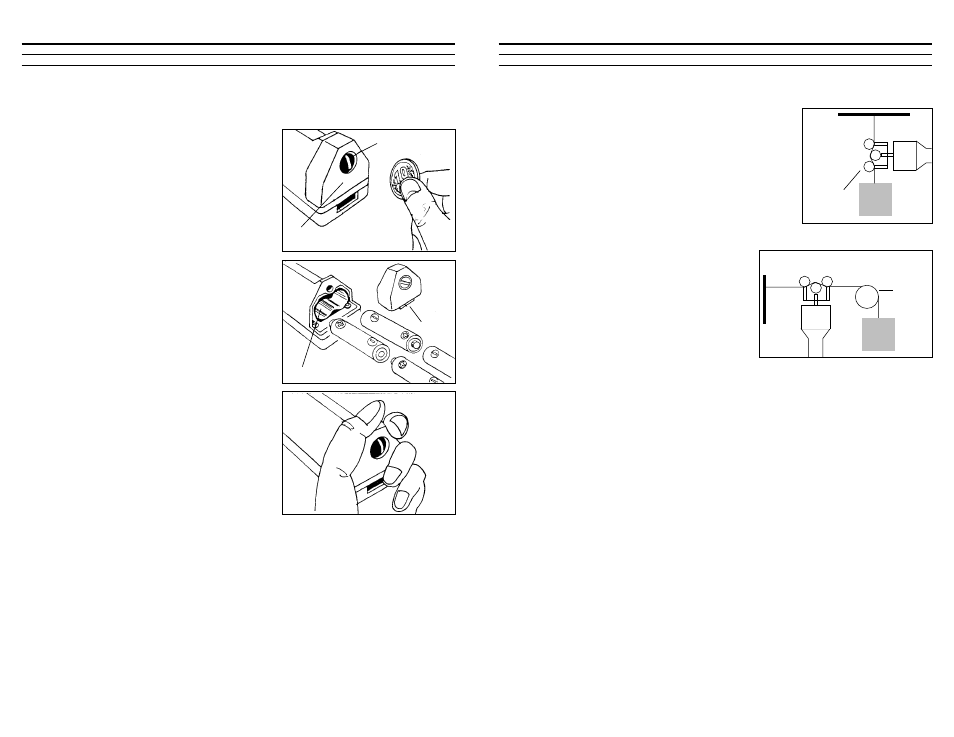

1. Using a slotted screwdriver or coin,

loosen the battery cover screw located

at the end of the unit by turning the

screw counterclockwise.

2. Insert four (4) AA , 1.5 volt akaline

batteries into the battery sleeve.

Insert them in the direction indicated

on the top of the sleeve. Use of NiCad

rechargeable batteries is not

recommended.

3. Replace battery cover by first inserting

the tab of the cover into the slot of the

housing and pressing the cover into

place. Tighten the screw by turning it

clockwise.

NOTES:

1. If battery cover will not close, confirm that the batteries are inserted in the

proper orientation. Refer to step 2 above.

2. After replacing the battery, make sure the proper units of measure are

selected.

Battery cover screw

Battery cover

Battery sleeve

Battery

cover

tab

17

7.10 Checking Calibration

It is important to check the calibration of the DTMB

frequently to insure that the gauge continues to

perform within factory specifications. Implementing

a periodic calibration check will help identify when

(and if) the gauge goes out of calibration due to

unreported damage, overload, or other unknown

reason.

To check the calibration:

1. Suspend a known weight “W” from the

process material in either a vertical or

horizontal direction, best simulating the

orientation that will be used during

actual measurement. Fix the process

material at one end.When fixing the

process material horizontally, use a

roller (or other free-rotating guide) prior to fixing the known weight. Refer to

sketches. Select a weight within the expected operating tension range of the

the application

2. Setup DTMB by inserting sample into Thickness Compensator and

performing a Gravity Correction (Zero) if using a horizontal material path.

Refer to QuickStart Instructions, Section 4.0.

3. The DTMB should display a value equal to (or within quoted accuracy

specification) of the known Weight “W”. If not, refer to Field Calibration

Adjustment, Section 7.20.

W

Horizontal Material Path

W

Vertical

Material

Path

Roller

Roller