Ti-44n operating instruction guide – Checkline TI-44N User Manual

Page 9

6.1

Acoustic Velocity Selection Table

ACOUSTIC VELOCITY SELECTION TABLE

Material

Acoustic

Equivalent

Equivalent

Type Velocity

Value

Value

Of

(meters/sec)

Of Calibration Calibration Disc

Disc (Inch)

Disc (mm)

Aluminum

6260

.208

5.3

Acrylic (Plexiglass)

2700

.090

2.3

Cast Iron

4400-5000

.148 - .168

3.8 - 4.3

Ceramics

10000

.332

8.4

Copper

4700

.156

3.9

Duralumin (17S)

6320

.211

5.3

Ebonite

2500

.083

2.1

Glass

5570

.185

4.7

Nickel

6040

.201

5.1

Polyethylene (Soft)

1900

.063

1.6

Polyvinyl Chloride (PVC)

2300-2500

.077-.083

1.9 - 2.1

Quartz (X cut)

5720

.191

4.9

Stainless Steel (SUS304)

5790

.193

4.9

Stainless Steel (SUS403)

6100

.205

5.2

Stainless Steel (SUS410)

7390

.246

6.2

Steel

5930

.197

5.0

Tin

3320

.110

2.8

Zinc (Zn)

4170

.139

3.5

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆ Denotes one of the 10 preset values in Mode C.

TI-44N Operating Instruction Guide

9

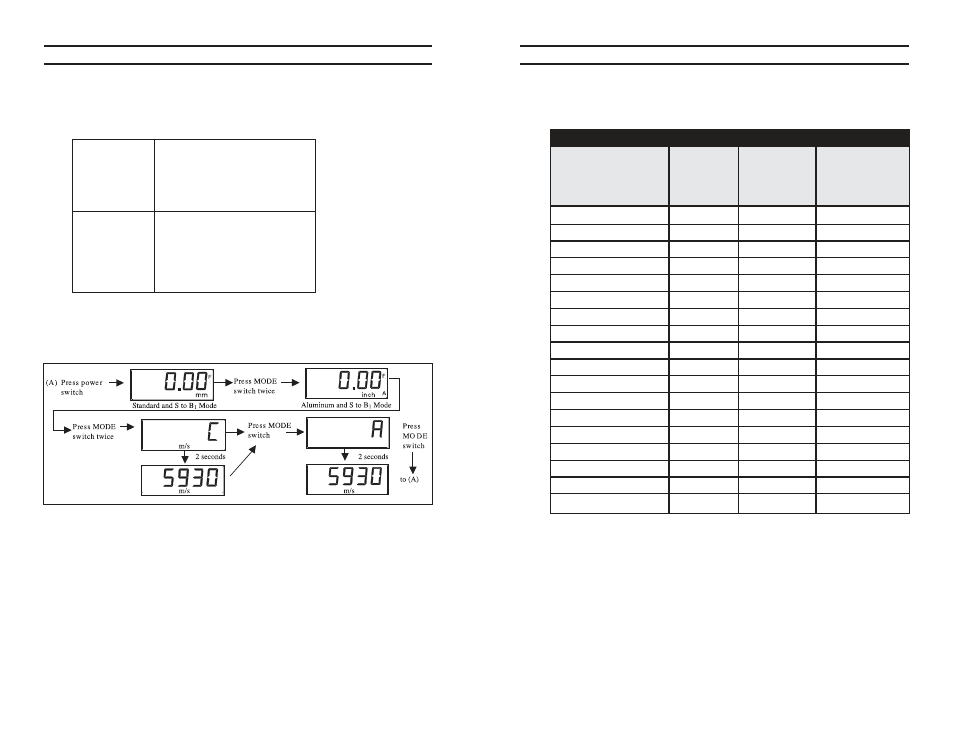

6.5

Changing Modes

Flow of mode selection:

S to B1 measurement method

Standard

Thickness value

Measurement

Ex.: 5.00 mm

F/ H appears on the extreme

right in Free / Hold mode,

respectively.

Aluminum

Thickness value followed by A

Measurement

Ex.: 5.00 mm_A

F/H appears on the extreme

right in Free/Hold mode,

respectively.

TI-44N provides two measurement modes depending

upon the nature of the test material (Standard and

Aluminum mode), which can be easily switched by

MODE switch operation:

Pressing and holding the MODE switch for longer than two seconds always

toggles back and forth between the Free and Hold modes.

Free mode is the correct choice for almost all applications. Select the Hold

mode when readings fluxuate and stable measurement cannot be obtaned.

TI-44N Operating Instruction Guide

12