Ti-44n operating instruction guide – Checkline TI-44N User Manual

Page 3

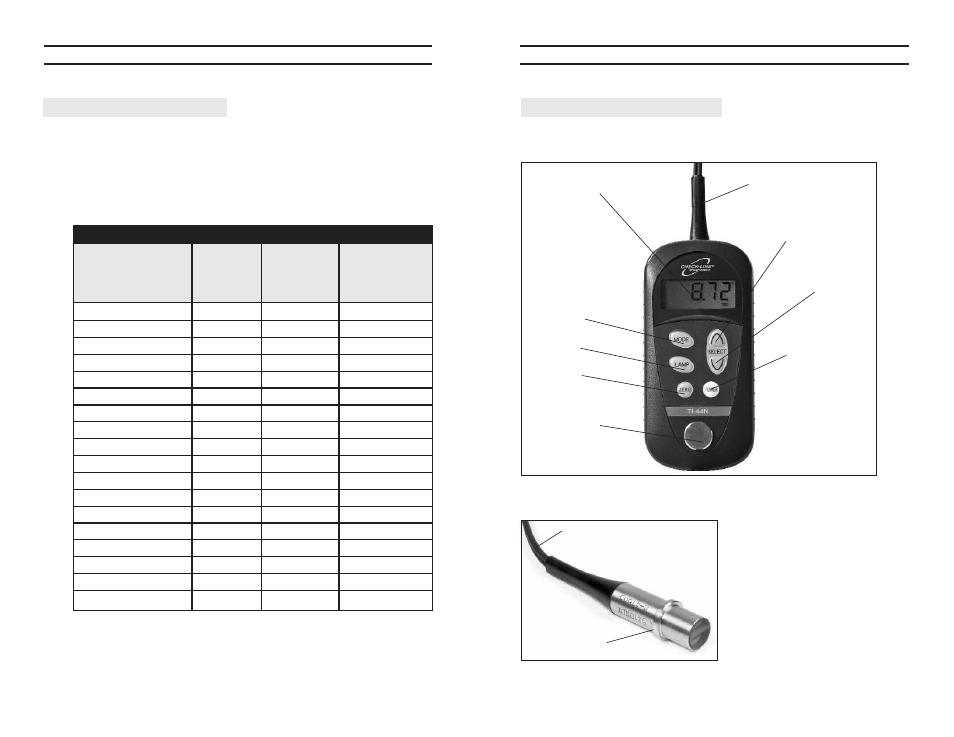

Mode Selector

Back Light

On/Off

Probe Zero

Test Plate for

Zero Adjustment

Equivalent to 0.197"

(5.00 mm) steel

On/Off Switch

Hard-wired cable and probe

LCD Display

Increase Sonic

Velocity

or Thickness

Adjustment

Decrease Sonic

Velocity or

Thickness

Adjustment

Probe

3.0 D

ESCRIPTION OF

G

AUGE

3.1 Gauge

3.2 Probe

Assembly

Probe Cable: Do not bend sharply.

Do not bring into contact with high

temperature objects (> 60 °C)

TI-44N Operating Instruction Guide

3

A

PPENDIX

The TI-44N Thickness Gauge is supplied from the factory set for an acoustic

velocity of 5930 m/sec for the measurement of steel. To measure the thickness of

any other material, the acoustic velocity must be changed. When checking the

built-in calibration sample, the gauge will display the “Equivalent Value” listed in

the Table in section 6.1, instead of 0.197" (or 5.0 mm)

ACOUSTIC VELOCITY SELECTION TABLE

Material

Acoustic

Equivalent

Equivalent

Type Velocity

Value

Value

Of

(meters/sec)

Of Calibration Calibration Disc

Disc (Inch)

Disc (mm)

Aluminum

6260

.208

5.3

Acrylic (Plexiglass)

2700

.090

2.3

Cast Iron

4400-5000

.148 - .168

3.8 - 4.3

Ceramics

10000

.332

8.4

Copper

4700

.156

3.9

Duralumin (17S)

6320

.211

5.3

Ebonite

2500

.083

2.1

Glass

5570

.185

4.7

Nickel

6040

.201

5.1

Polyethylene (Soft)

1900

.063

1.6

Polyvinyl Chloride (PVC)

2300-2500

.077-.083

1.9 - 2.1

Quartz (X cut)

5720

.191

4.9

Stainless Steel (SUS304)

5790

.193

4.9

Stainless Steel (SUS403)

6100

.205

5.2

Stainless Steel (SUS410)

7390

.246

6.2

Steel

5930

.197

5.0

Tin

3320

.110

2.8

Zinc (Zn)

4170

.139

3.5

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆ Denotes one of the 10 preset values in Mode C.

TI-44N Operating Instruction Guide

18