Checkline TI-44N User Manual

Page 10

6.2

Setup Of Gauge When Acoustic Velocity Is Unknown

In applications where the type of material is not known or the material type

is not listed in the Acoustic Velocity Selection Table the following steps can

be performed to set the gauge to measure accurately.

1. Measure a sample of the material using a micrometer, caliper or similar

measuring device.

2. Turn the power on by pressing the

POW

key.

3. Place a small amount of couplant fluid on the sample and place the probe

on the sample.

4. After a thickness value is shown on the LCD display along with the Good

Coupling Indicator, remove the probe from the sample.

5. Use the

▲

and

▼

keys to increase or decrease the displayed value until

it equals the known thickness of the sample as measured in Step 1. When

the

▲

key is pressed the “UP” indicator will be show on the LCD display.

The “LOW” indicator will be shown for the

▼

key.

6. The acoustic velocity setting will be automatically adjusted to the correct

value for this material after Step 5 is completed.

7 . Change modes to either Mode C or Mode A to display the current acoustic

velocity, as described in section 6.4. Write this value down so it can be

re-entered without having to repeat the above procedures should you need

to change the acoustic velocity to another setting.

6.3

Changing Acoustic Velocity Settings

After determining the required acoustic velocity for the material to be

measured, the acoustic velocity must be adjusted by using either of the

following methods:

• Selecting one of the ten (10) preset values [Mode C, Coarse Adjustment]

• Adjusting the velocity to the desired setting [Mode A, Fine Adjusment]

METHODS FOR CHANGING ACOUSTIC VELOCITY SETTINGS

MODE Select one from

Use ▲ or ▼

Last Setting ➔1900 ➔2700 ➔

C

a list of 10

keys to index

➔

4170 ➔ 4700 ➔ 5570 ➔ 5790

Preset Values

thru selections

➔

5930 ➔ 6260 ➔7390 ➔10000

MODE Fine Adjustment

Use ▲ or ▼

Any acoustic value can be set

A

to desired value

keys to increase

from 1000 to 12000 m/sec

or decrease value

TI-44N Operating Instruction Guide

10

6.4

Thickness Measurement Methods

(a) Standard mode vs. aluminum mode

The instrument is shipped with the standard sensitivity settings suitable

mainly for steel measurement. In addition to this, it provides an aluminum

measurement mode with lower sensitivity (approx. 10 dB less than the

standard mode).

High-sensitivity equipment will often pick up too much noise when

measuring materials with small ultrasonic attenuation (e.g. aluminum),

resulting in erroneous thickness values.

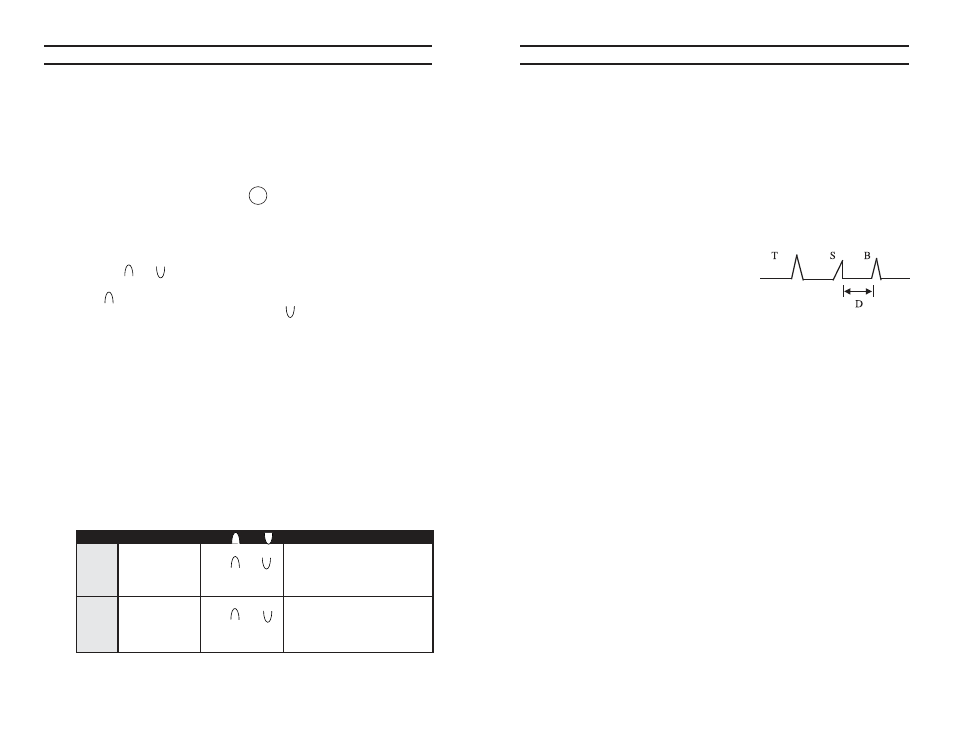

(b) S to B 1 method

Thickness (D) is determined using the

time difference between the upper surface

reflection (S-echo) and the first bottom

surface reflection (B-echo). This method

is mainly used for steel measurement.

TI-44N Operating Instruction Guide

11