Ti-44n operating instruction guide – Checkline TI-44N User Manual

Page 6

4.3

Turning The Power ON

Turn on the power by pressing the

POW

key. The current acoustic velocity

setting will be momentarily displayed prior to entering the Measurement

Mode (Mode H). The display should then read 0.000 inch (or 0.00 mm).

If the Good Coupling Indicator is flashing on and off, the red transmit

connector of the probe is not connected properly.

4.4

Turning The Power OFF

The Power will turn off automatically after three (3) minutes of non-use.

To manually turn off the power, press & hold the

POW

key for 3 sec.,

then release.

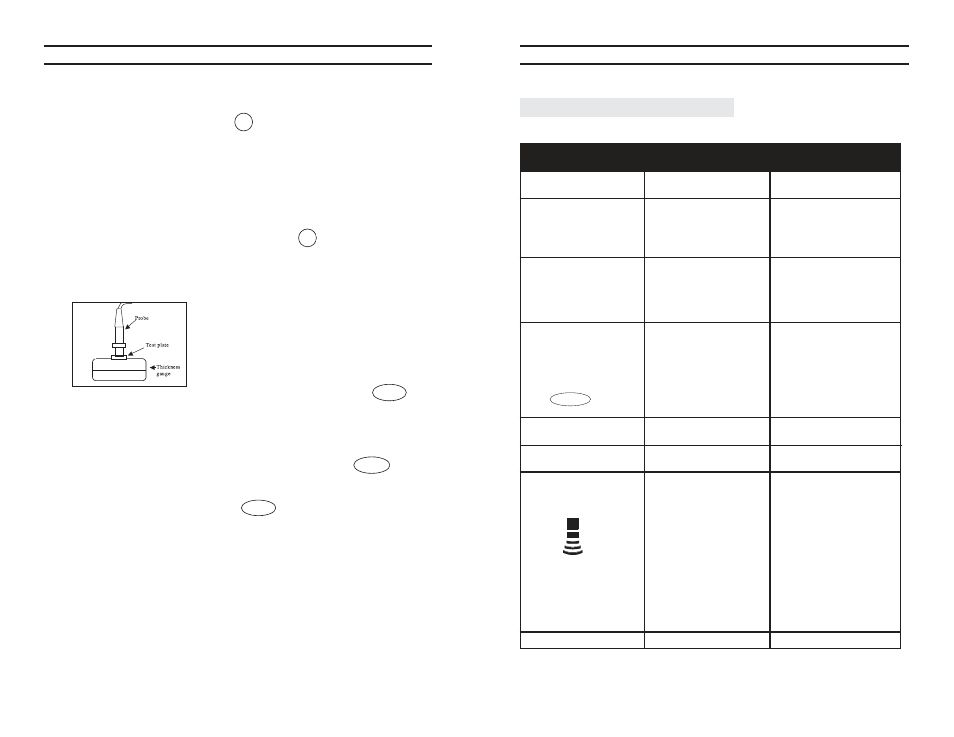

4.5 Zero Adjustment

This operation adjusts the zero point of the probe. Zero adjustment data is stored in

the instrument. It is recommended that the zero

adjustment data be refreshed once a day, preferably

before starting the day’s work.

1 .

Apply couplant on the test plate surface and

place the probe on it.

2 .

Make sure the probe is in good contact with

the test plate surface and press the

ZERO

switch.

3 . The zero adjustment procedure takes place and the display reads 0.197" or

5.00 mm when the process has been successfully completed.

NOTE: When the sonic velocity is set to a value other than 5390 m/s, the

display reads 0.197" or 5.00 momemtarily when the

ZERO

switch

is pressed. Zero adjustment is nonetheless proceeding correctly.

If the material to be tested is signifcantly larger or smaller than

0.197" or 5.00mm, and the ZERO switch is pressed, the display

will read --- -and the zero adjustment process becomes invalid. In

this case, the zero adjustment should be made on a sample of known

thickness of the test material itself.

4.6 Using Couplant Fluid

Apply couplant fluid to the mesuring surfacae before measurement. The

couplant eliminates air between the probe and test surface, promoting the

transmission of the ultrasonic pulse.

NOTE: Never use organic solvents, including thinners and alcohols.

The surface must be cleaned of couplant after measurement.

TI-44N Operating Instruction Guide

6

8.0 T

ROUBLE

-S

HOOTING

G

UIDE

Description of Problem

Possible Cause

Action To Be Taken

Gauge will not power

Battery voltage may be

Replace with new AA

up

too low

battery

Gauge will not power

• New battery may be

• Check battery voltage

up even though battery

too weak

(should be

≈

1.5 Volt)

has been replaced

• Back-up battery (lithium)

• Return gauge for a new

could be too weak

lithium battery

Good Coupling

• Probe or cable could be

• Clean probe & surface

Indicator flashes on/off

defective

and retry measurement

• Foreign substance may

• Return to manufacturer

be trapped between

for inspection/repair

probe and sample

Good Coupling

• Insufficient couplant fluid

• Add more couplant

Indicator not shown

• Paint or coating is too

• Grind off paint and/or

thick or voids and/or

corrosion

corrosion lies under paint

“......” is displayed

Probe could be degraded

Return to manufacturer

when ZERO key is

or defective

for inspection or repair

pressed

Displayed thickness

Acrylic probe face is

Carefully sand face of

value is unstable

deteriorated

probe using #500 paper

Can’t obtain measure-

Pipe diameter (OD) may

Consult factory

ment on small dia. pipe

be less than 1”

(25 mm)

Couping indicator does

• Insufficient amount of

• Apply additional couplant

not appear while measure-

couplant

ment is being taken

• Test material surface is

• Grind/polish measuring

too rough

surface to 50-100-s

smoothness

• Test material bottom

• Change measurement

surface is too rough

point

• Too much ultrasonic

• Change measurement

attenuation due to

point

material composition

• Test material thickness is

• Change measurement

outside the proper

point

measuring range

Fluxuating readings

Defective probe

Return to manufacturer

TI-44N Operating Instruction Guide

15