Checkline TI-CMXDL User Manual

Page 33

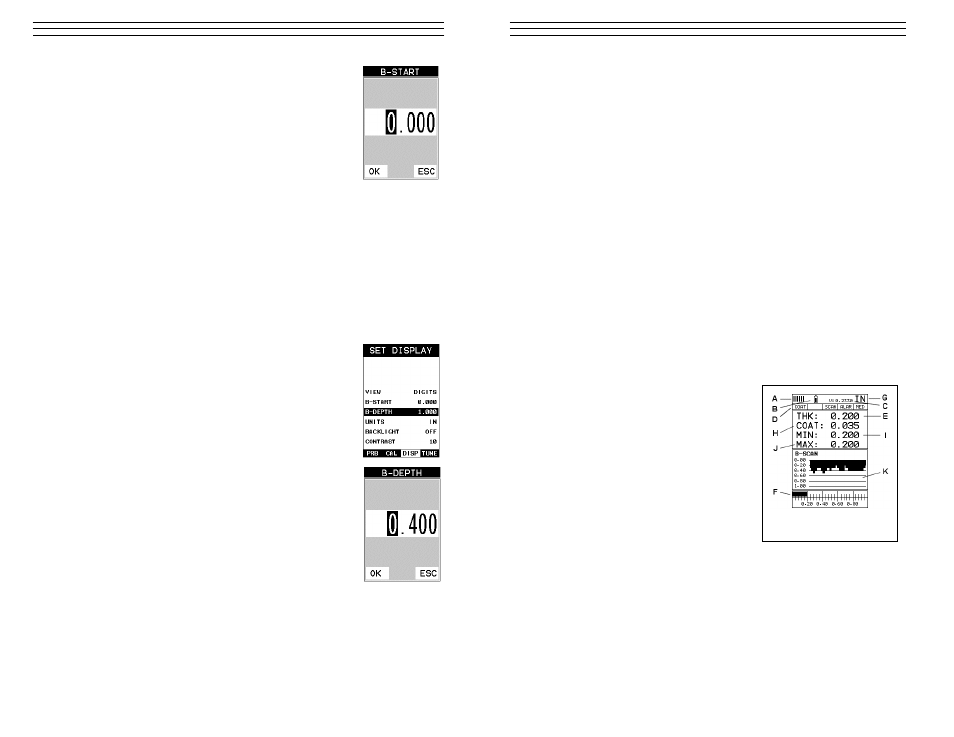

C. Velocity – The material velocity value the TI-CMXDL is currently using or calibrate

for. Displayed in English or Metric units, depending on the what units the gauge is se

for.

D. Feature Status Bar – Indicates the features currently enabled and in use in the

following order:

•

Measurement Mode

•

Differential Mode

• High Speed Scan Mode

• Alarm Mode

• Gain

Setting

E. Digital Material Thickness Value – Extra large font size for viewing ease.

F. Scan Bar – Another view of material thickness in a deflection style horizontal bar. Th

is another visual tool that would enable the user the ability to see thickness changes

during high speed scans from flaws and pits.

G. Units – The current measurement units being used (English, Metric).

H. Coating Thickness Value – Displays the actual thickness of any coating adhered to a

metallic material surface (PECT Mode), or a coating adhered to a non-metallic surfac

(CT Mode).

I. Minimum Material Thickness – Part of the Alarm feature. Displays the

minimum thickness value found during a scan.

J. Maximum Material Thickness – Part of the Alarm feature. Displays the maximum

thickness value found during a scan.

B-Scan

The B-Scan displays a time based cross section

view of test material. This is a visual tool that

enables the user to see the contour of the blind,

or underside, surface of a pipe or tank applica-

tion. It is very similar to a fish finder. If a flaw

or pit is located during a scan, the B-Scan will

draw the pit on the screen.

The solid black rectangle in the diagram at

location K represents the cross section, or side

view of the material. The B-Scan view draws

at a rate of 7 seconds per screen from right to

left. Also notice at location K, the pits and

corroded bottom surface of the material.

It’s important to note that the measurement range on the display be set wide enough,

so that the maximum thickness of the material can be viewed on the display. Using the

diagram above, if the material thickness was actually 1.75”, the underside of the materia

would not be viewable according to the current range at 0.00” – 1.00”. All the user woul

see is a black screen from 0.00” – 1.00” with no view of the bottom contour at 1.75”.

-33-

B-Scan View

4. Alternatively, press the ENTER key to display the Digits

Edit Box.

5. Press the UP and DOWN arrow keys to scroll the highlighted

value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

7. Repeat steps 5 & 6 until the B-Start value is correctly

displayed.

8. Press the OK key to set the B-Start value and return to the

menu screen, or ESC to cancel entering the B-Start.

9. Finally, press the MEAS key to return to the measurement screen and begin taking

readings.

Overall range (B-DEPTH)

Once again, just to reiterate, B-DEPTH is the overall viewable thickness range being test-

ed. This should be set to a value slightly larger then the expected maximum range being

measured. The procedures to adjust the overall thickness range viewed (B-DEPTH) are out-

lined below:

Adjusting the Overall Depth (B-DEPTH)

1. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right, and the

ESC key multiple times to tab left, until the DISP menu is

highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the

sub menu items until B-DEPTH is highlighted.

3. Press the LEFT and RIGHT arrow keys to scroll the value.

When the correct width is being displayed, proceed to step 8.

4. Alternatively, press the ENTER key to display the Digits Edit

Box.

5. Press the UP and DOWN arrow keys to scroll the highlighted

value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

7. Repeat steps 5 & 6 until the B-Scan Depth value is correctly

displayed.

8. Press the OK key to set the B-SCAN Depth and return to the

menu screen, or ESC to cancel entering the B-Depth.

9. Finally, press the MEAS key to return to the measurement screen

and begin taking readings.

-36-