Checkline TI-CMXDL User Manual

Page 3

2.0 Q

UICK

-S

TART

G

UIDE

Turn the TI-CMXDL on and off using the switch located on the bottom right corner of the key

pad. When TI-CMXDL is initially turned on, a flash logo and blinking lights are displayed. Th

the gauge attempts to identify the currently attached transducer (probe). The TI-CMXDL has a

“Auto Probe Recognition” feature that attempts to identify special transducers with feature bui

in . If the TI-CMXDL doesn’t find a transducer so equipped, the user must select a transducer

from the Probe Type list. The following sections outline each scenario.

NOTE: This section is primarily written as a basic startup guide only.

2.1 TI-CMXDL

Overview

In order to understand how to operate the TI-CMXDL, it’s best to start off with an

understanding of what it is we’re looking at exactly. The TI-CMXDL has a lot of great

features and tools that will prove to be a huge benefit for the variety of applications you

constantly facing on a continual basis. Let’s have a brief look at the screens you’ll be

ºlooking at most often:

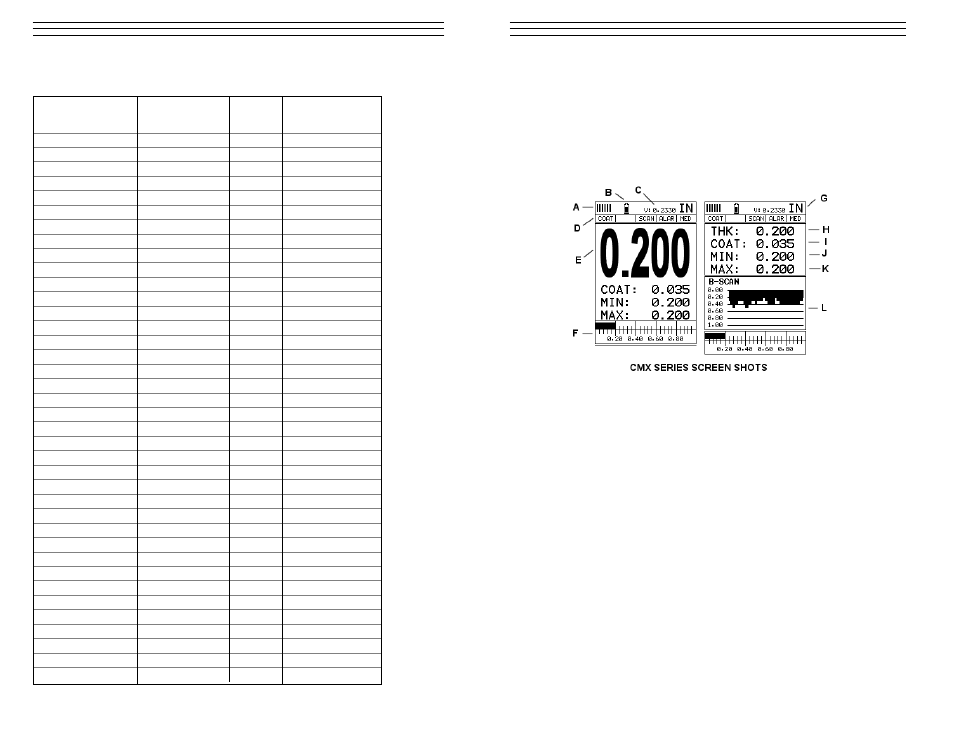

A. Repeatability/Stability Indicator – This indicator should be commonly used in con

junction with the digital thickness values displayed. When all the vertical bars are ful

illuminated and the last digit on the digital thickness value is stable, the TI-CMXDL

reliably measuring the same value 3 to 200 times per second, depending on which

measurement mode and features are enabled.

B. Battery Icon – Indicates the amount of battery life the TI-CMXDL has remaining.

C. Velocity – The material velocity value the TI-CMXDL is currently using or calibrated

Displayed in English or Metric units, depending on the what units the gauge is set for.

D. Feature Status Bar – Indicates the features currently enabled and in use in the

following order:

• Measurement Mode

• Differential Mode

• High Speed Scan Mode

• Alarm Mode

• Gain Setting

E. Digital Material Thickness Value – Extra large font size for viewing ease.

-3-

-66-

A

PPENDIX

A: V

ELOCITY

T

ABLE

Material

sound velocity

sound velocity

in/us

m/s

Aluminum

0.2510

6375

Beryllium

0.5080

12903

Brass

0.1730

4394

Bronze

0.1390

3531

Cadmium

0.1090

2769

Columbium

0.1940

4928

Copper

0.1830

4648

Glass (plate)

0.2270

5766

Glycerine

0.0760

1930

Gold

0.1280

3251

Inconel

0.2290

5817

Iron

0.2320

5893

Cast Iron

0.1800

(approx)

4572

Lead

0.0850

2159

Magnesium

0.2300

5842

Mercury

0.0570

1448

Molybdenum

0.2460

6248

Monel

0.2110

5359

Nickel

0.2220

5639

Nylon

0.1060

(approx)

2692

Platinum

0.1560

3962

Plexiglas

0.1060

2692

Polystyrene

0.0920

2337

PVC

0.0940

2388

Quartz glass

0.2260

5740

Rubber vulcanized

0.0910

2311

Silver

0.1420

3607

Steel (1020)

0.2320

5893

Steel (4340)

0.2330

5918

Steel Stainless"

0.2230

5664

Teflon

0.0540

1372

Tin

0.1310

3327

Titanium

0.2400

6096

Tungsten

0.2040

5182

Uranium

0.1330

3378

Water

0.0580

1473

Zinc

0.1660

4216

Zirconium

0.1830

4648