California Faucets Tile Styledrain Set with No-Hub User Manual

Page 2

1

9190_ii_121022.doc

Pg

2

2

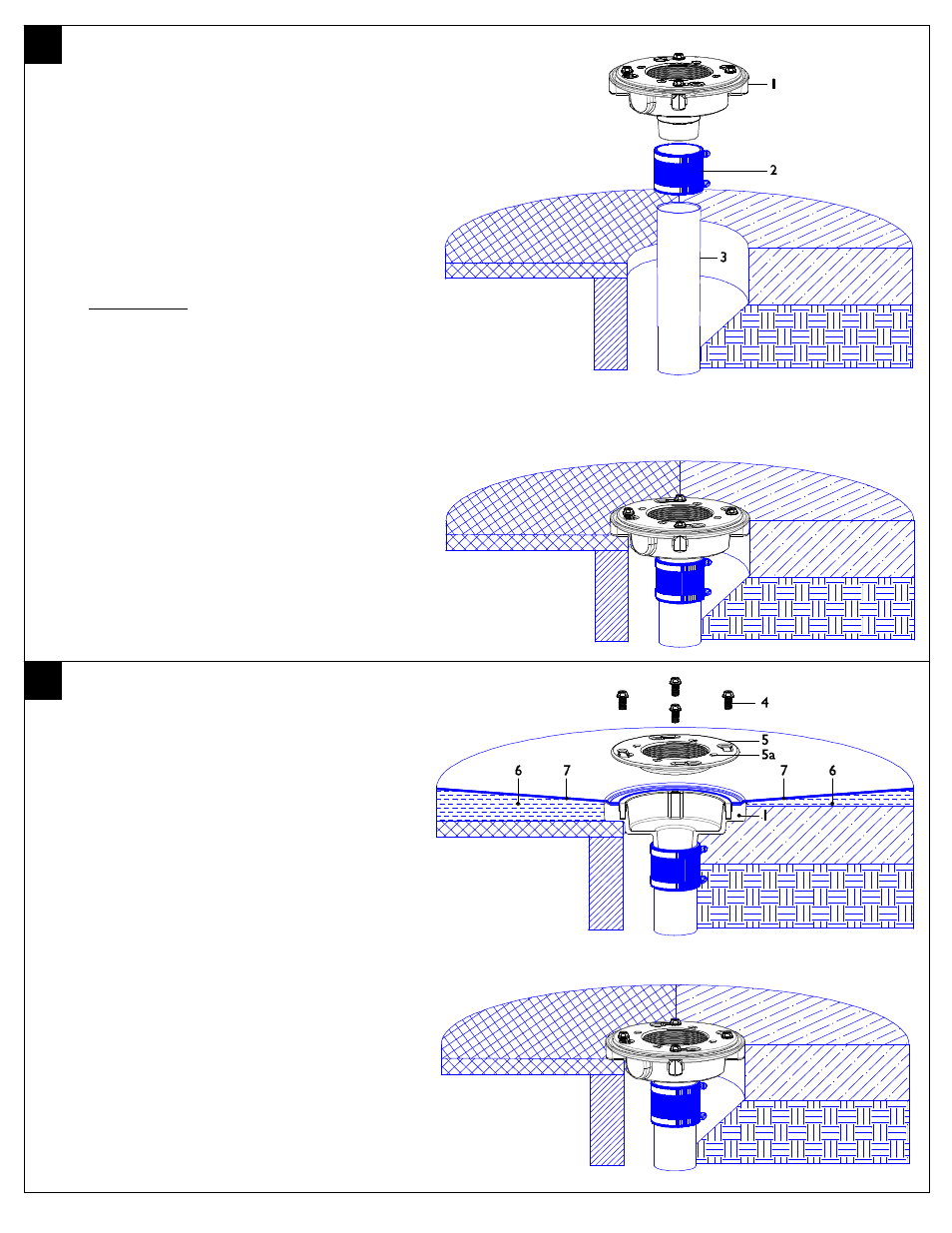

INSTALLING DRAIN BODY

Ø6-1/4” (Cast Iron)

Ø7-5/8” (ABS/PVC)

• Connect BODY (1) to pre-installed DRAINPIPE (3)

via one of the following connections which are not

included:

o

2” Cast Iron No-Hub use 2” no-hub SLEEVE (2)

o

3” Cast Iron No-Hub use 3” no-hub sleeve

o

2” or 3” Cast Iron IPS use 2” or 3” pipe nipple

o

2”/3” ABS use ABS solvent cement

o

2”/3” PVC use PVC solvent cement

NOTE: It may be necessary to trim excess DRAINPIPE (3) to obtain

proper final installation height

• For wood sub-floor installations the following cut hole

sizes shall be made to properly support the installed

drain BODY (1):

o

Ø

6-1/4” for ALL cast iron bodies

o

Ø

7-5/8” for ALL ABS and PVC bodies

• Perform leak test in accordance with local building &

plumbing codes before proceeding

• For proper support on drain BODY (1) use one of

the following methods based on installation type:

o

Wood sub-floor: provide framing support of drain

BODY (1) and strapping of DRAINPIPE (3)

o

Concrete sub-floor: backfill with dirt and concrete

around drain BODY (1)

INSTALLING WATERPROOFING

NOTE: All waterproofing materials shall be installed per manufactures

instructions and local building & plumbing codes. The following is a guide

as to how waterproofing relates to the StyleDrain

®

Tile

™

• Loosen or remove BOLTS (4) and remove COLLAR

(5) from drain BODY (1)

• Use MORTAR (6) or similar to achieve proper

drainage (generally ¼” per linear foot) then apply

WATERPROOFING (7) on top of MORTAR (6)

• Reattach COLLAR (5) in either down or up position

based on desired height requirements and/or local

building & plumbing codes, tighten BOLTS (4) to

secure COLLAR (5) into place

NOTE: When COLLAR (5) is installed in up position an additional 7/8”

in height is achieved

IMPORTANT: It is necessary that WEEP HOLES (5a) are open and

free of WATERPROOFING (7)

IMPORTANT: Perform water leak testing of WATERPROOFING (7)

per manufactures and local building & plumbing codes requirements