3 function, 1 digestion process – BUCHI KjelDigester K-449 User Manual

Page 21

4 – 21

Operation Manual

KjelDigester K-446/K-449

4 Description of function

4.3 Function

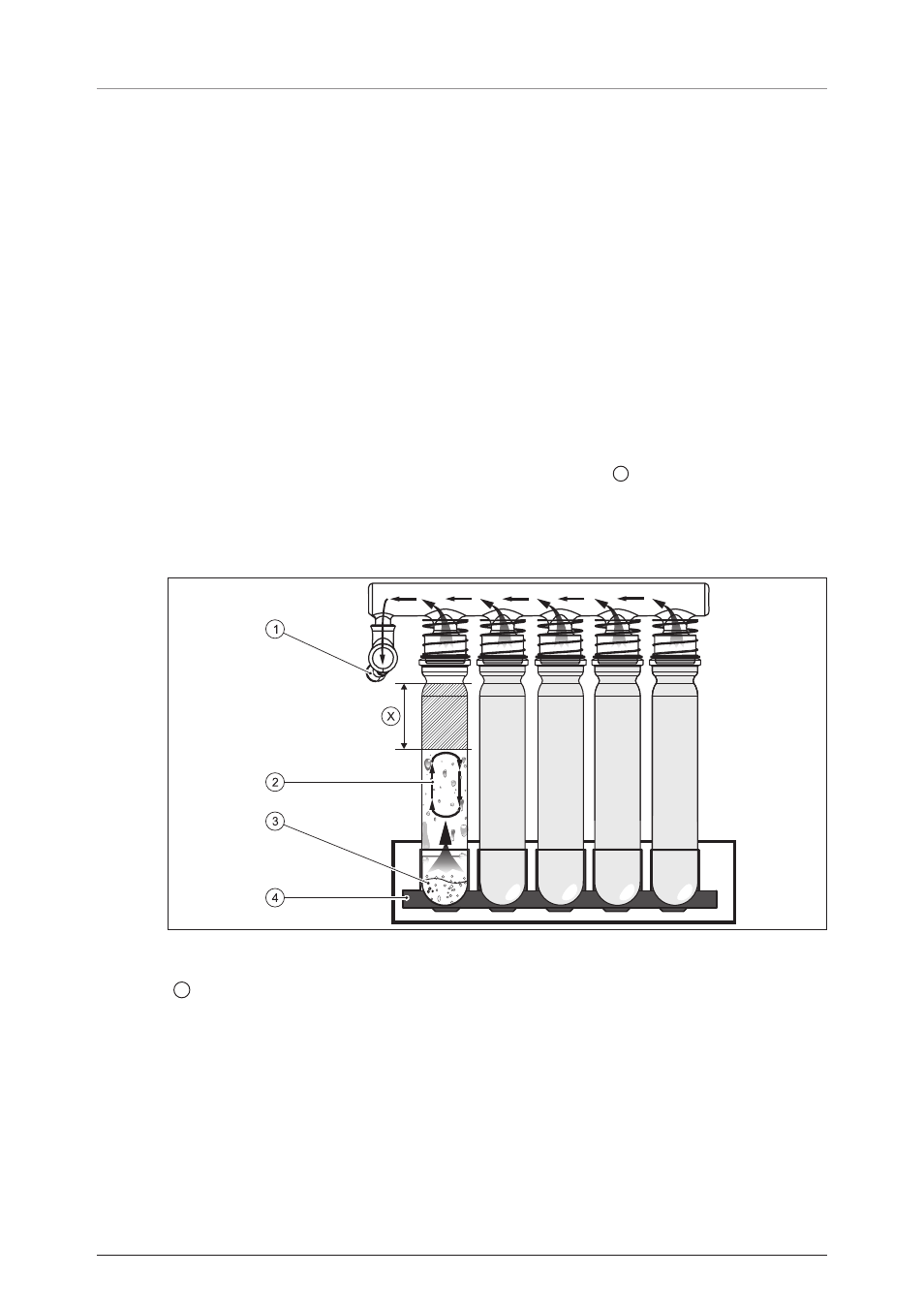

The KjelDigester is used to convert organic bound nitrogen (e.g. in proteins) in a sample into

ammonium sulfate. During the digestion process, acid fumes and reaction gases may emerge

and are handled by the Scrubber. The Scrubber is connected to the KjelDigester for neutralizing

acid fumes and adsorbing unpleasant odors.

4.3.1 Digestion process

The aluminum heating block d generates high temperatures of up to 450 °C in order to heat the

sample c up to 370 °C (boiling point). The sample is digested in constantly boiling H

2

SO

4

. Hot

acid fumes rise into the condensation zone b, condense and rinse back down to the sample

creating a constant reflux. Residual fumes which escape the condensation zone via the acid

fume outlet a are highly corrosive and must be withdrawn and efficiently neutralized (e.g. with

the Scrubber K-415).

The condensation should not take place inside the safety zone

X

in order to avoid shortening

the lifetime of the sealings. In case the condensation is too close to the suction module (e.g. due

to very high temperature settings or if too much catalyst was used) losses of nitrogen through

creating N

2

are possible and the samples can dry out.

Fig. 4.4 Function of the KjelDigester

X

Safety zone

c Boiling/digestion sample

a Acid fume outlet

d Heating block

b Condensation zone