Brookfield DV-I Viscometer User Manual

Page 23

Brookfield Engineering Laboratories, Inc.

Page 23

Manual No. M/92-021-O604

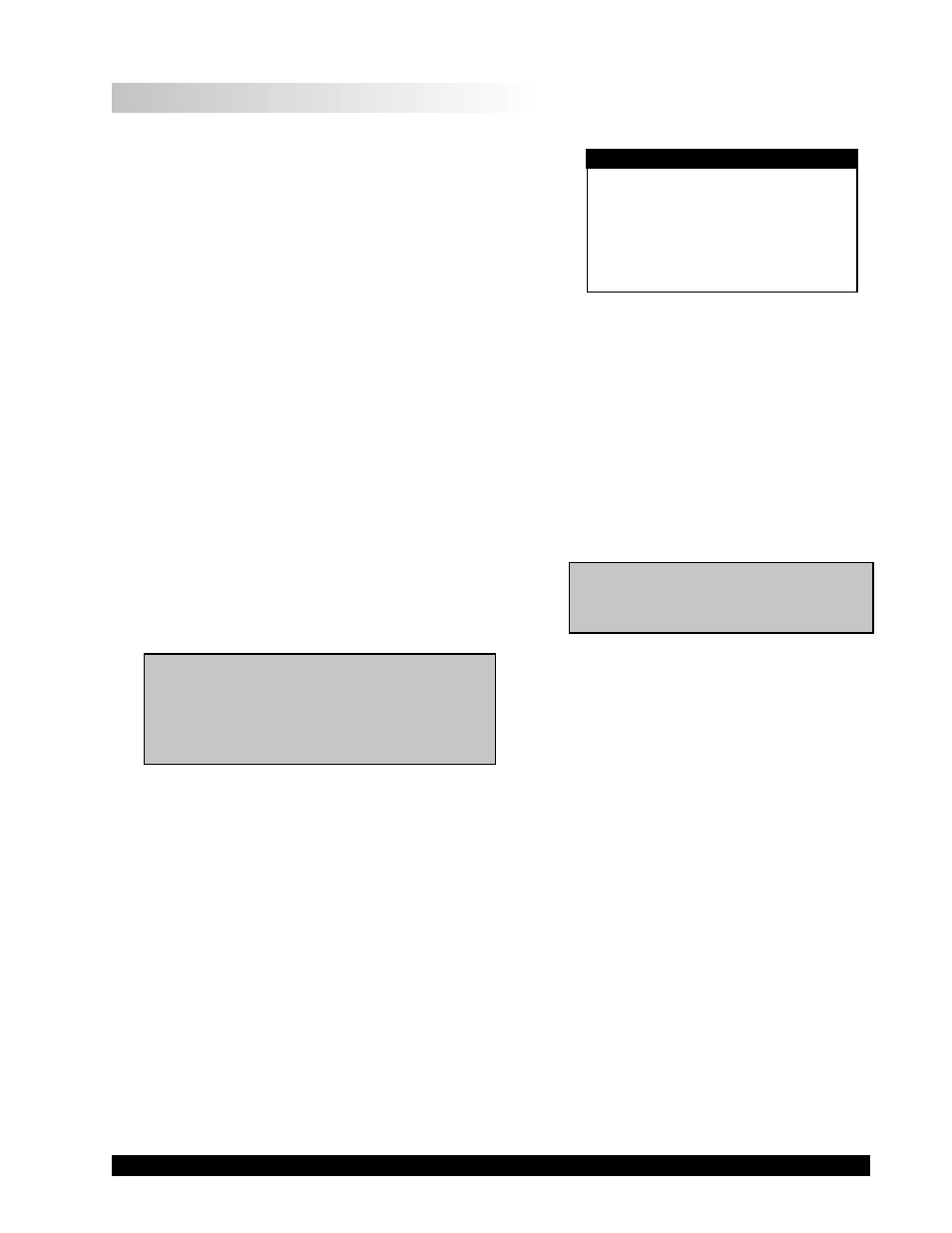

C o n e

S a m p l e Vo l u m e

P a r t N o .

C P E - 4 0

0 . 5 m l

C P E - 4 1

2 . 0 m l

C P E - 4 2

1 . 0 m l

C P E - 5 1

0 . 5 m l

C P E - 5 2

0 . 5 m l

Ta b l e A 6

Table A-1

4. Attach the sample cup to the Viscom-

eter and allow sufficient time for the

sample, cup and cone to reach tem-

perature equilibrium.

5. Turn the motor on. Set the desired

speed(s). Measure the viscosity and

record the reading in both % torque

and centipoise (cP).

NOTE: The cone spindle must rotate

at least five (5) times before a visco-

sity reading is taken.

6. Verify that the viscosity reading is

within the allowable 1% deviation, as

explained earlier, for the specific vis-

cosity standard fluid(s) that you are

using.

*

The CPE designation on the cone

spindle indicates use with Electronic

Gap Setting Cone/Plate Viscometers/

Rheometers only.

A.4 VERIFYING CALIBRATION

1.

Determine the appropriate sample volume.

Refer to Table A-1 to determine the correct

sample volume required for the spindle to be

utilized.

2.

Select a Brookfield Viscosity Standard fluid

that will give viscosity readings between 10%

and 100% of full scale range. Refer to Ap-

pendix B for viscosity ranges of cone spindles;

ranges listed apply to CPE cones.

Do not use a silicone viscosity standard fluid

with a viscosity value greater than 5000 cP

with a Cone/Plate. Brookfield offers a com-

plete range of mineral oil viscosity standards

suitable for use with Cone/Plates for viscosi-

ties above 5,000 cP or shear rates above 500

sec

-1

; see Table E1 in Appendix E for a list of

available fluids.

It is best to use a viscosity standard fluid that

will be close to the maximum viscosity for a

given cone spindle/speed combination.

Example: LVDV-I+ Viscometer, Cone

Spindle CPE-42, Brookfield

Silicone Viscosity Standard

having a viscosity of 9.7 cP at

25

°

C.

At 60 RPM, the full scale viscosity range is

10.0 cP. Thus, the Viscometer reading should

be 97% torque and 9.7 cP viscosity

±

0.197

(closer to

±

0.2) cP. The accuracy is a combi-

nation of Viscometer and fluid tolerance (re-

fer to Interpretation of Calibration Test

Results in Appendix E).

3.

With the motor off, remove the sample cup

and place the viscosity standard fluid into the

cup.