Installation maintenance and cleaning – STIEBEL ELTRON Accelera 300 E User Manual

Page 24

24

| Accelera® 220-300 E www.stiebel-eltron-usa.com

INSTALLATION

Maintenance and cleaning

14.3 Cleaning the evaporator

!

WARNING Injury

The evaporator consists of numerous sharp-edged fi ns.

Be careful during cleaning the evaporator and wear pro-

tective clothing, especially safety gloves.

The evaporator fi ns are coated with a hydrophilic coating to reduce

corrosion and to eliminate surface tension on condensed water

droplets. This creates a self-cleaning action so minimal cleaning

is necessary. Nevertheless, the evaporator should still be checked

for contamination and corrosion and cleaned as necessary.

Undo the screw that secures the appliance cover at the upper side

of the control panel.

Remove the control panel and the appliance cover.

Carefully clean the evaporator fi ns. Use water and a soft

brush for this. Never use acidic or alkaline cleaning agents.

14.4 Draining the tank

WARNING Burns

Hot water may escape when draining the DHW tank.

To drain the DHW tank, e.g. when shutting the appliance down,

proceed as follows:

Unplug the appliance from the power supply.

Close the shut-off valve in the cold water supply line.

The DHW tank is drained via the cold water supply line.

Open the drain valve installed in the cold water supply line

(See 10.1, “Water connection”, pg. 19). If no drain valve

has been installed, undo the cold water supply line at the

“cold water inlet” connection.

Open one tap in one sink.

Some residual water will remain in the lower section of the DHW

tank.

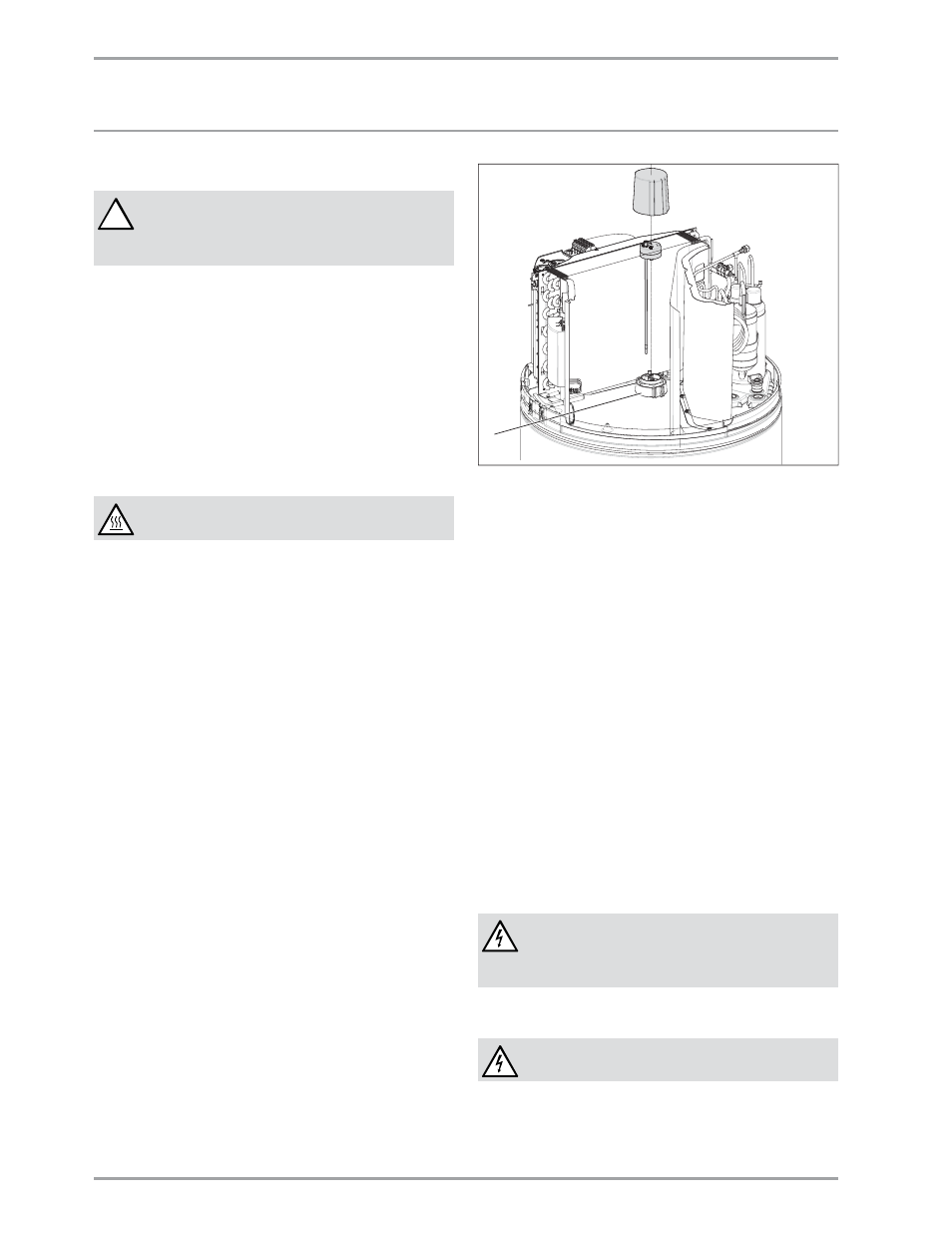

14.5 Descaling the electric booster element

Only descale the fl ange of the electric booster element after re-

moving it, and never treat the interior of the DHW tank and the im-

pressed current anode with descaling agents. The electric booster

element is screwed into the appliance at a central point at the top.

D00000

34

79

9

1

1 Electric booster element with protective anode

14.6

Protective

anode

The fl ange of the electric booster element is equipped with a

protective anode that protects the appliance from corrosion while

it is connected to the power supply. The protective anode is a

maintenance-free impressed current anode.

If a fault code in the display indicates that the protective anode is

faulty, proceed as follows:

Remove the controller of the electric booster element.

Check the protective anode connector and its wiring.

Refi t the controller of the electric booster element.

14.7

Valves

Regularly check the system's valves (safety valve, pressure reduc-

ing valve, drain valve, vacuum breaker, mixing valve), to ensure the

operational reliability of the appliance. The amount of lime-scale

deposits depends on local water quality.

Check all valves in the system and remove lime-scale

deposits.

Replace the valves if necessary.

Check the function of the valves.

14.8 Replacing the power cable

WARNING Electrocution

If the power cable is faulty, replace it with a new one.

The power cable should only be replaced by a qualifi ed

contractor.

14.9 Fitting the casing ring

WARNING Electrocution

Reconnect the ground wire to the casing ring.