Caution – Steffes 6140 User Manual

Page 16

Installation

n

3.07

Comfort Plus Commercial

Installation

Step 3 Locate the plenum support bracket shipped in the

plenum box. Attach the bracket to the supply air side

using the blunt tip screws supplied in the plenum

assembly hardware package. Refer to Figure 8 for

proper positioning of the plenum support bracket.

Step 4 Attach the supply blower wiring harness located in the

base of the system to the blower using the connections

located on the ends of the harness. Be sure to place any excess

wiring in the base of the system below the radiant heat shield

(Figure 8).

Step 5 Verify that the blower is installed in the plenum with the motor

facing away from the system (Figure 9).

Step 6 Attach the supply air blower plenum to the Comfort Plus Commer-

cial System by drilling two 1/8 holes per edge and using the self

tapping screws supplied in the hardware package.

Step 7 Connect both the return air and supply air ducting systems in the

structure to the system. Be sure the air holes just above the air

outlet on the right side are contained in the duct system. (See

Figure 8 for reference to the location of these holes.)

If the system is installed in an enclosed area (less than 400 square feet), a minimum of a

24"x 24" opening must be installed into the area where the system is located. In

addition, a 6" x 6" non-closing type register can be cut into the return air duct. Refer to

Placement and Clearance Requirements section (Pages 3.02-3.03) for more information.

Step 8 Connect the supply air duct in the structure directly to the system's air outlet located on the top panel.

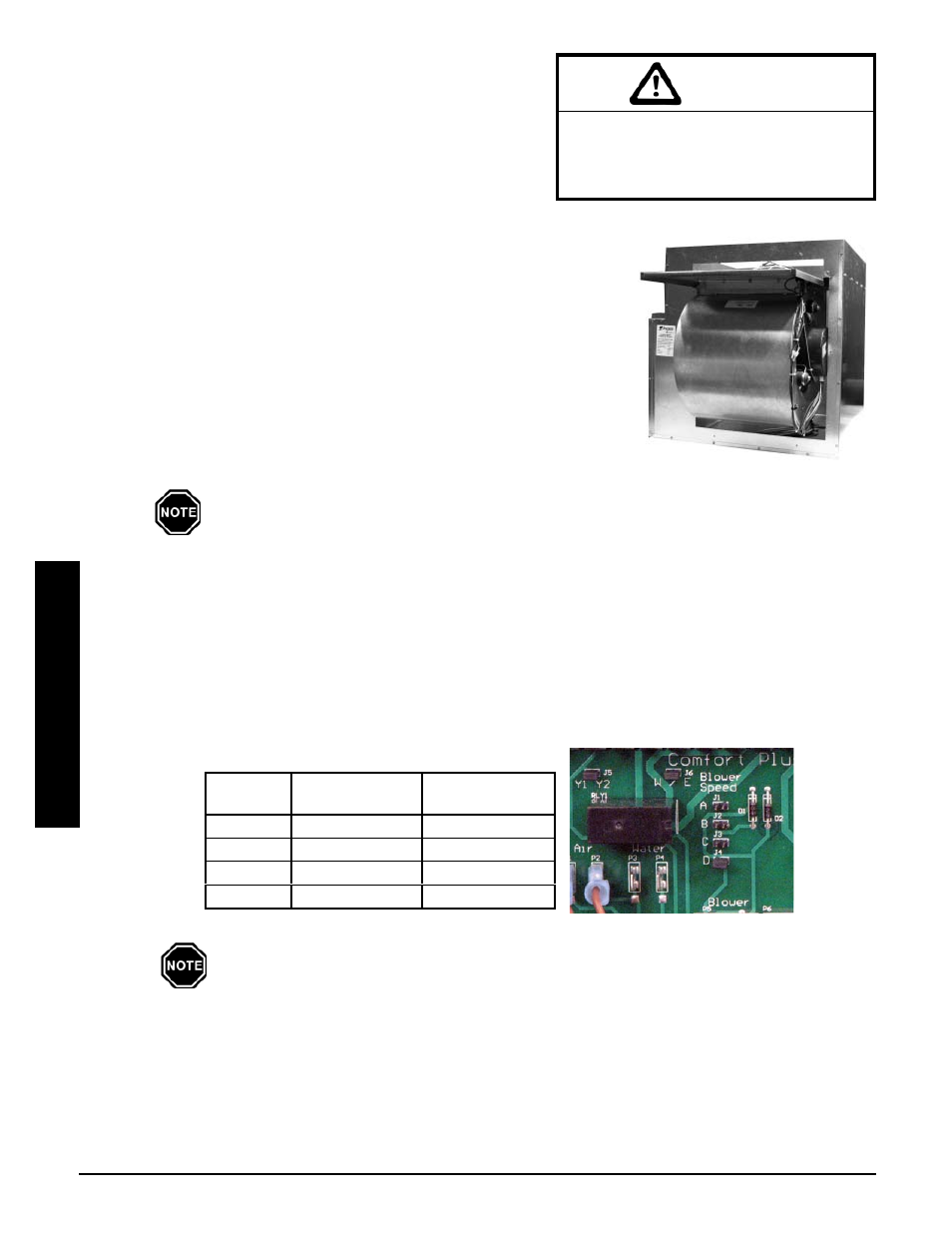

Step 9 Blower speed selection is configured by moving the blower speed jumper (Figure 10) to the desired

position. Reference the System Air Delivery Matrix for CFM information.

Step 10 The W/E jumper (Figure 10) MUST be in the ON position or the blower will not operate with an E call

from the thermostat.

When routing the harness to the supply

air blower, the harness must route to the

side of the air deflector in the bottom of

the supply air blower housing.

CAUTION

w

External static pressure should not exceed .75 inches water column.

w

With 2 stage Heat Pump, a Stage 1 heat call results in 50% of selected CFM.

w

Generally, 400 CFM of air flow is recommended per ton of cooling. Therefore,

a 3-ton heat pump or air conditioner would require 1200 CFM.

FIGURE 9

Jumper

½ HP Variable

Speed CFM

1 HP Variable

Speed CFM

A 1000 1200

B 1200 1400

C 1400 1600

D 1600 2000

SYSTEM AIR DELIVERY MATRIX

VARIABLE SPEED MOTOR

FIGURE 10