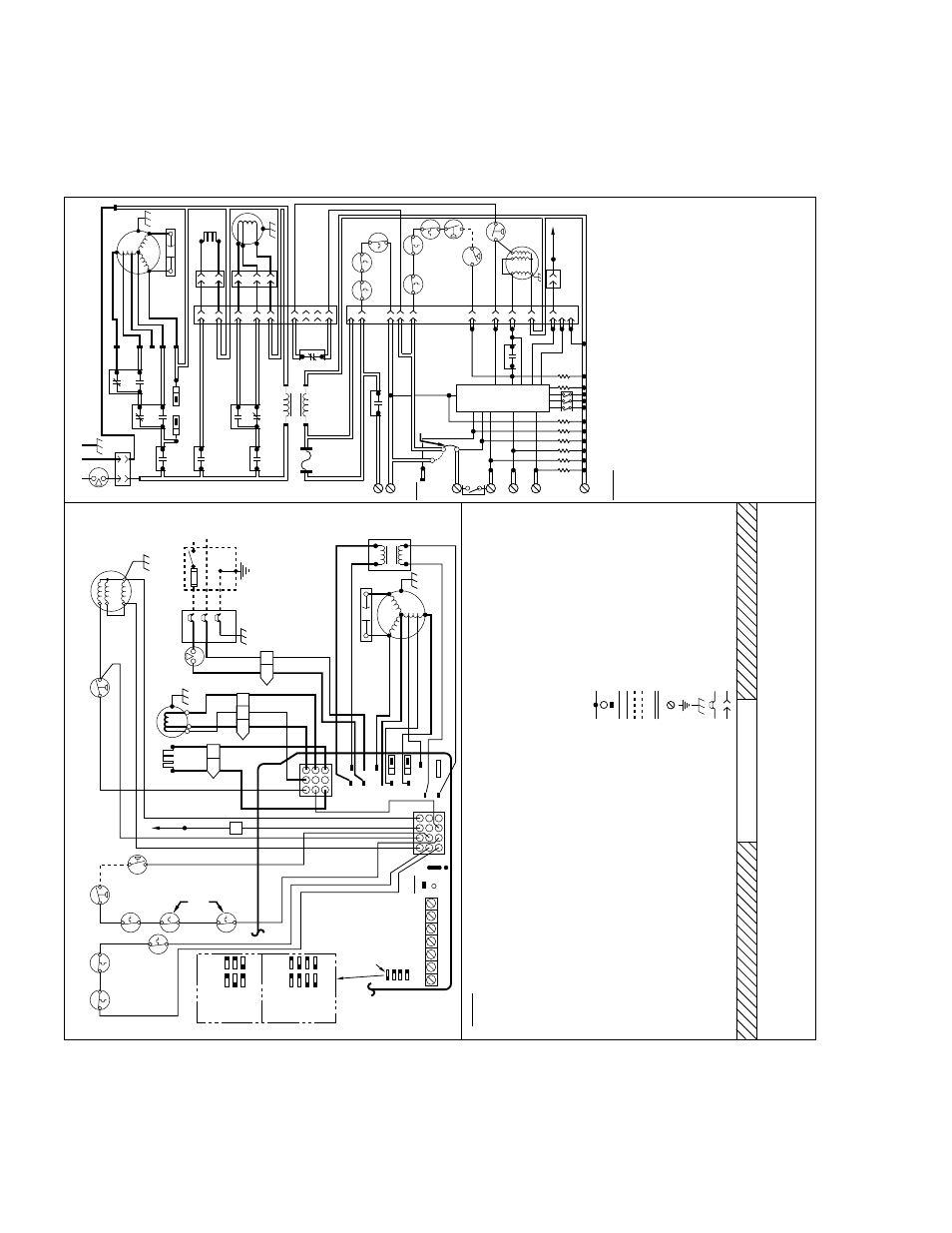

Fig. 12—unit wiring diagram, Component test – Carrier 58TMA User Manual

Page 8

Fig.

12—Unit

Wiring

Diagram

A94232

FUSED DISCONNECT

SWITCH (WHEN REQ'D)

NOTE #1

JB

WHT

BLK

GRN

GRN

FU2

COMPONENT TEST

To initiate the component test sequence with no thermostat inputs and with all inducer Post-Purge and

Blower-Off Delay periods completed, short the 'TWIN/TEST' terminal to the 'COM' terminal for about two

seconds. The control will turn ON the inducer motor Low-Speed, inducer motor High-Speed, HSI,

blower motor Low-Gas-Heat Speed, blower motor High-Gas-Heat Speed, and blower motor High-Cool

Speed for 7-15 seconds each. Neither the gas valve nor the humidifier will be turned ON.

ALS1

ALS2

BHI/LOR

BHT/CLR

BLWM

BLWR

CAP

CPU

DSS

EAC-1

EAC-2

FRS1

FRS2

FSE

FU1

FU2

GV

HPS

HPSR

HSI

HSIR

HUM

IDM

IDR

IHI/LOR

ILK

JB

LED

LGPS

LPS

LS

MGVR

LEGEND

AUXILIARY LIMIT SWITCH, OVERTEMP.–MANUAL RESET, SPST-(N.C.)

AUXILIARY LIMIT SWITCH, OVERTEMP.–AUTO. RESET, SPST-(N.C.)

BLOWER MOTOR SPEED CHANGE RELAY, SPDT

BLOWER MOTOR SPEED CHANGE RELAY, SPDT

BLOWER MOTOR, 4-SPEED, PERMANENT-SPLIT-CAPACITOR

BLOWER MOTOR RELAY, SPST-(N.O.)

CAPACITOR

MICROPROCESSOR AND CIRCUITRY

DRAFT SAFEGUARD SWITCH

ELECTRONIC AIR CLEANER CONNECTION (115 VAC 1 AMP MAX.)

ELECTRONIC AIR CLEANER CONNECTION (COMMON)

FLAME ROLLOUT SWITCH OVERTEMP.–MANUAL RESET, SPST-(N.C.)

FLAME ROLLOUT SWITCH OVERTEMP.–MANUAL RESET, SPST-(N.C.)

FLAME-PROVING SENSOR ELECTRODE

FUSE, 3 AMP, AUTOMOTIVE BLADE TYPE, FACTORY INSTALLED

FUSE, FIELD INSTALLED

GAS VALVE-REDUNDANT LOW-HEAT OPERATORS, 2-STAGE

HIGH-HEAT PRESSURE SWITCH, SPST-(N.O.)

HIGH-HEAT PRESSURE SWITCH RELAY, SPST-(N.C.)

HOT-SURFACE IGNITOR (115 VAC)

HOT-SURFACE IGNITOR RELAY, SPST-(N.O.)

24VAC HUMIDIFIER CONNECTION (

.

5 AMP MAX.)

INDUCED DRAFT MOTOR, 2-SPEED, SHADED–POLE

INDUCER MOTOR RELAY, SPST-(N.O.)

INDUCER MOTOR SPEED CHANGE RELAY, SPDT

BLOWER DOOR INTERLOCK SWITCH, SPST-(N.O.)

JUNCTION BOX

LIGHT-EMITTING DIODE FOR STATUS CODES

LOW GAS-PRESSURE SWITCH, SPST-(N.O.)

LOW-HEAT PRESSURE SWITCH, SPST-(N.O.)

LIMIT SWITCH, OVERTEMPERATURE-AUTO RESET, SPST-(N.O.)

MAIN GAS VALVE RELAY, DPST-(N.O.)

–

1 = VALVE –

2 = HUMIDIFIER

PL1

PL2

PL3

PL4

PL6

PL7

SW1

SW2

SW3 & 4

TJ

TRAN

TWIN/TEST

12-CIRCUIT CONNECTOR

9-CIRCUIT CONNECTOR

3-CIRCUIT IDM CONNECTOR

1-CIRCUIT FPS CONNECTOR

2-CIRCUIT HSI CONNECTOR

2-CIRCUIT LINE/NEUTRAL CONNECTOR

HIGH-HEAT-ONLY SWITCH, SPST-(MANUAL)

*

LOW-HEAT-ONLY SWITCH, SPST-(MANUAL)

*

BLOWER-OFF DELAY SETTING SWITCHES,

SPST-(MANUAL)

*

TWINNING JUMPER, SPDT FOR MASTER OR

SLAVE STATUS-(MANUAL CHANGE-OVER)

TRANSFORMER-115VAC/24VAC

1-CIRCUIT TWINNING BUSS CONNECTOR,

ALSO STATUS CODE RECALL

JUNCTION

TERMINAL

CONTROL TERMINAL

FACTORY POWER WIRING (115VAC)

FACTORY CONTROL WIRING (24VAC)

FIELD POWER WIRING (115VAC)

FIELD CONTROL WIRING (24VAC)

CONDUCTOR ON CONTROL

FIELD WIRING SCREW TERMINAL

FIELD GROUND

EQUIPMENT GROUND

FIELD SPLICE

PLUG RECEPTICLE

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

USE ONLY COPPER WIRE BETWEEN THE DISCONNECT SWITCH AND

THE UNIT.

IF ANY OF THE ORIGINAL WIRE, AS SUPPLIED, MUST BE REPLACED, USE

THE SAME OR EQUIVALENT TYPE WIRE.

INDUCER (IDM) AND BLOWER (BLWM) MOTORS CONTAIN INTERNAL AUTO-

RESET THERMAL OVERLOAD SWITCHES.

BLOWER MOTOR SPEED SELECTIONS ARE FOR AVERAGE CONDITIONS.

SEE INSTALLATION INSTRUCTIONS FOR DETAILS ON OPTIMUM SPEED

SELECTION.

REPLACE ONLY WITH A 3-AMP FUSE.

AUXILIARY LIMIT SWITCHES (ALS1 & 2) USED ON DOWNFLOW MODELS

ONLY.

THIS WIRE MUST BE CONNECTED TO FURNACE SHEET METAL FOR

CONTROL TO PROVE FLAME.

FACTORY CONNECTED WHEN LGPS NOT USED.

SYMBOLS ARE AN ELECTRICAL REPRESENTATION ONLY.

BLOWER-ON DELAY: GAS HEATING 45 SECONDS, COOLING/HEAT PUMP 2

SECONDS.

COOLING/HEAT PUMP BLOWER-OFF DELAY IS 90 SECONDS.

IGNITION-LOCKOUT WILL OCCUR AFTER FOUR CONSECUTIVE UNSUC-

CESSFUL TRIALS-FOR-IGNITION. CONTROL WILL AUTOMATICALLY RESET

AFTER THREE HOURS.

CONTROL MUST BE GROUNDED AT PIN 10 OF 12-PIN CONNECTOR.

NA - NOT APPLICABLE

NOTES:

320854-401 REV. D

LS

FRS2

NOTE #8

LPS

CONNECTION DIAGRAM

RED

RED

RED

FRS1

(WHEN USED)

HEAT

SET-UP

SWITCH

NORM

HI HT

LO HT

SWITCH

1

2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SWITCH

3

4

BLOWER-OFF

DELAY

(SEC.)

90 SEC

135 SEC

180 SEC

225 SEC

2-STAGE

FURNACE

CONTROL

BLOWER-OFF DELAY

1

4

23

BLOWER-OFF DELAY

LOW-HEAT ONLY

HIGH-HEAT ONLY

ON

OFF

W2

Com

24V

W/

W1

Y/

Y2

R

G

HUM

TWIN

TEST

LED

1

2

3

TJ

M

S

RED

RED

ORN

YEL

RED

ORN

ORN

YEL

NOTE

#8

DSS

LGPS

ALS1

(WHEN USED)

NOTE

#6

ALS2

ORN

BRN

BLU

WHT

GRN

10

11

12

P1

1

2

3

7

8

9

BLK

GRY

SEC2

PR1

PR2

L1

L2

COMMON

HI-COOL

HI-GAS

HEAT

SEC1

LO-GAS

HEAT

EAC-2

EAC-1

PARK

FU1

PL2

YEL

(WHEN USED)

1

PL

4

WHT

FSE

1

2

BLK

PL6

HSI

WHT

IDM

GRN

RED

WHT

BLK

1

2

3

PL3

RED

BLK

WHT

BRN

GRY

BRN

HPS

HI

P

M

C

GRN

GRN

BLU

L1

L2

1

2

WHT

BLK

ILK

WHT

BLK

PL7

BLK

WHT

CAP

BRN

BRN

NOTE #4

COM

HI

MED HI

MED LO

LO

RED

BLU

WHT

BLK

YEL

BLU

RED

BLWM

RED

BLU

WHT

BLK

TRAN

SCHEMATIC DIAGRAM

(NATURAL GAS & PROPANE)

TO 115VAC FIELD DISCONNECT SWITCH

EQUIPMENT GROUND

ILK

L1

PL7

BLWR

HSIR

EAC-1

EAC-2

BHT

/CLR

BHI/LOR

LO-GAS-

HEAT

PARK

HI-COOL

COMMON

HI-GAS-

HEAT

LO

MED LO

MED HI

HI

COM

BLWM

L2

BRN

BRN

CAP

NOTE #4

IDR

IHI

/LOR

PR1

115VAC

24VAC

TRAN

PR2

SEC1

SEC2

FU1

NOTE #5

HPSR

HSI

PL6

PL3

1

2

2

1

3

3

9

4

7

8

1

5

6

2

LO

HI

COM

IDM

N

/A

N

/A

12

2

3

9

6

5

4

1

10

7

8

11

N

/A

FRS1

(WHEN USED)

FRS2

LS

MGVR-2

HUM

R

TWIN

TEST

SLAVE

MASTER

W/W1

SW1

W2

Y/Y2

G

C

OM

SW4

SW3

SW2

CPU

TWINNING

JUMPER

TJ

MGVR-1

PL1

N/A

N/A

PL4

FSE

M

P

C

NOTE#7

HI

GV

HPS

NOTE #8

LGPS

(WHEN USED)

NOTE #8

LPS

DSS

ALS1

ALS2

GV

FACTORY

SETTING

PL2

GRY

NOTE #1

*

*

*

8