Carrier 58TMA User Manual

Page 4

Lubricate motor every 5 years if motor is used on intermittent

operation (thermostat FAN switch in AUTO position), or every 2

years if motor is in continuous operation (thermostat FAN switch

in ON position).

Remember to disconnect the electrical supply before removing

access doors.

Clean and lubricate as follows:

1. Remove blower access door.

2. Disconnect vent pipe on downflow/horizontal furnace only.

a. Remove vent pipe enclosure.

b. Disconnect vent pipe and remove short piece of pipe from

furnace.

c. Disconnect wires from auxiliary limit on blower housing (if

present).

3. Disconnect blower electrical leads from control. (See Fig. 6

and 7.) Note location of wires for reassembly.

4. Remove control.

5. Remove screws holding blower assembly to blower deck and

slide blower assembly out of furnace.

6. Loosen a screw in strap holding motor capacitor to blower

housing and slide capacitor out from under strap.

7. Mark blower wheel, motor, and motor support in relation to

blower housing before disassembly to ensure proper reassem-

bly.

8. Loosen setscrew holding blower wheel on motor shaft.

9. Remove bolts holding motor and motor mount to blower

housing and slide motor and mount out of housing. Disconnect

ground wire attached to blower housing before removing

motor.

10. Lubricate motor (when oil ports are provided).

a. Remove dust caps or plugs from oil ports located at each

end of motor.

b. Use a good grade of SAE 20 nondetergent motor oil and

put 1 teaspoon, 5 cc, 3/16 oz, or 16 to 25 drops in each oil

port. Do not over-oil.

c. Allow time for total quantity of oil to be absorbed into each

bearing.

d. After oiling motor, be sure to wipe excess oil from motor

housing.

e. Replace dust cap or plugs on oil ports.

11. Remove blower wheel from housing.

a. Mark cutoff location to ensure proper reassembly.

b. Remove screws holding cutoff plate and remove cutoff

plate from housing.

c. Lift blower wheel from housing through opening.

12. Clean blower wheel and motor using a vacuum with soft brush

attachment. Do not remove or disturb balance weights (clips)

on blower wheel blades. The blower wheel should not be

dropped or bent as balance will be affected.

13. Reinstall blower wheel by reversing items 11 a. through c. Be

sure wheel is positioned for proper rotation.

14. Reassemble motor and blower by reversing items 5 through 9.

If motor has ground wire, be sure it is connected as before.

Be sure the motor is properly positioned in the blower

housing. The motor oil ports must be at a minimum of 45°

above the horizontal centerline of the motor after the blower

assembly has been reinstalled in the furnace.

15. Reinstall blower assembly in furnace.

16. Reinstall control. (See step C.13 for reassembly of vent pipe

and flue enclosure for downflow/horizontal furnaces.)

17. Connect blower electrical leads to control. Please note that

connections are polarized for assembly. DO NOT FORCE.

CLEANING HEAT EXCHANGER

The following steps should be performed by a qualified service

technician:

NOTE:

Deposits of soot and carbon indicate the existence of a

problem which needs to be corrected. Take action to correct the

problem.

If it becomes necessary to clean the heat exchanger because of

carbon deposits, soot, etc., proceed as follows:

1. Turn gas and power to furnace to OFF.

2. Remove control and blower access doors.

3. Remove vent pipe enclosure on downflow/horizontal furnace

only and disconnect vent pipe from relief box.

4. Remove 2 screws that secure relief box. (See Fig. 6 or 7.)

5. Disconnect wires to the following components. Mark wires to

aid in reconnection of:

a. Draft safeguard switch.

b. Inducer motor.

c. Pressure switch(es).

d. Limit overtemperature switch(es).

e. Gas valve.

f. Hot surface ignitor.

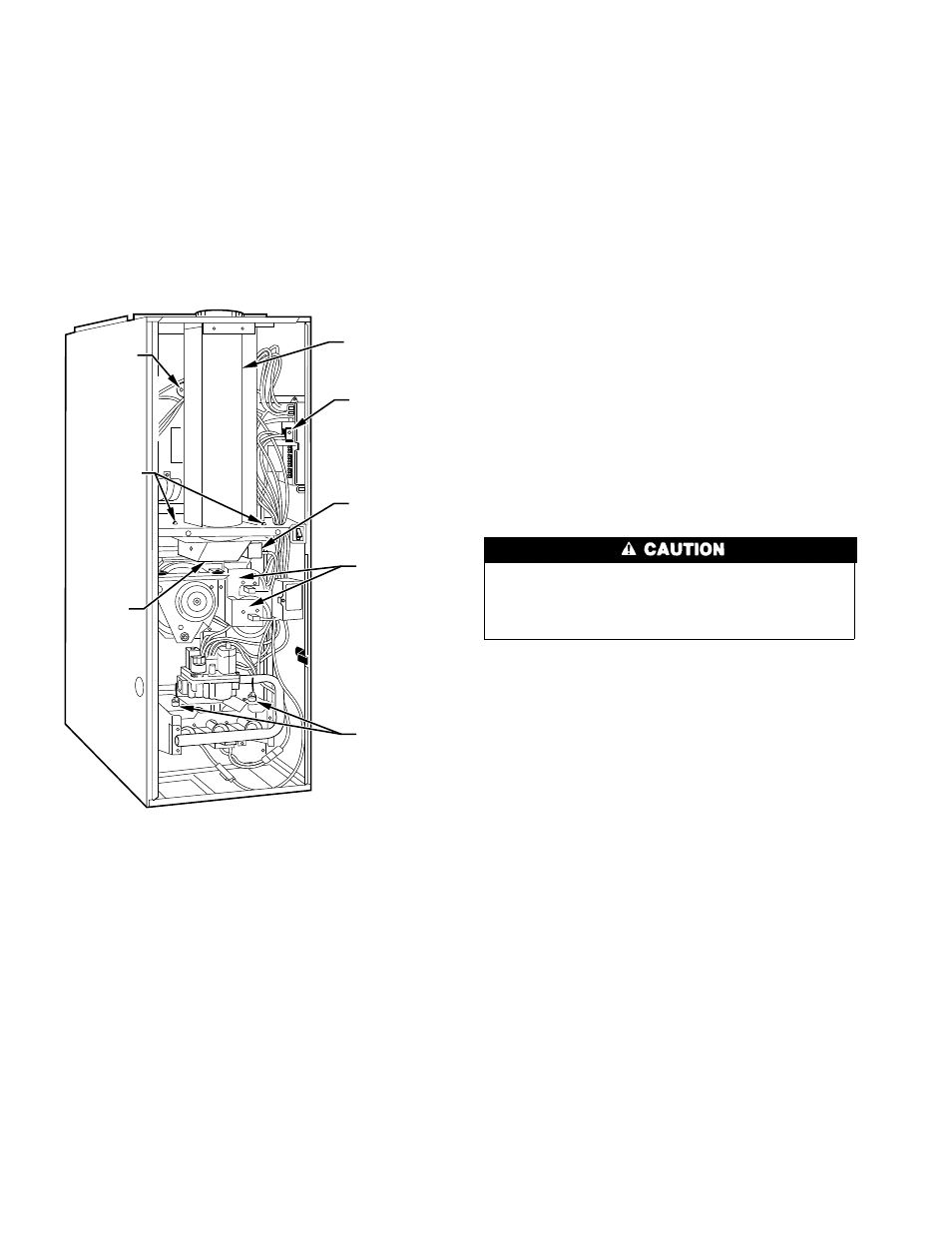

Fig. 7—Model 58TMA Downflow

A93394

PRESSURE

SWITCHES

VENT PIPE

ENCLOSURE

CONTROL

DRAFT

SAFEGUARD

SWITCH

AUXILIARY

LIMIT

SWITCH

MANUAL

RESET

LIMIT

SWITCHES

RELIEF

BOX

MOUNTING

SCREWS

4