Coolift – Magliner COOLIFT User Manual

Page 24

1-800-MAGLINE (624-5463)

Page 24 www.magliner.com

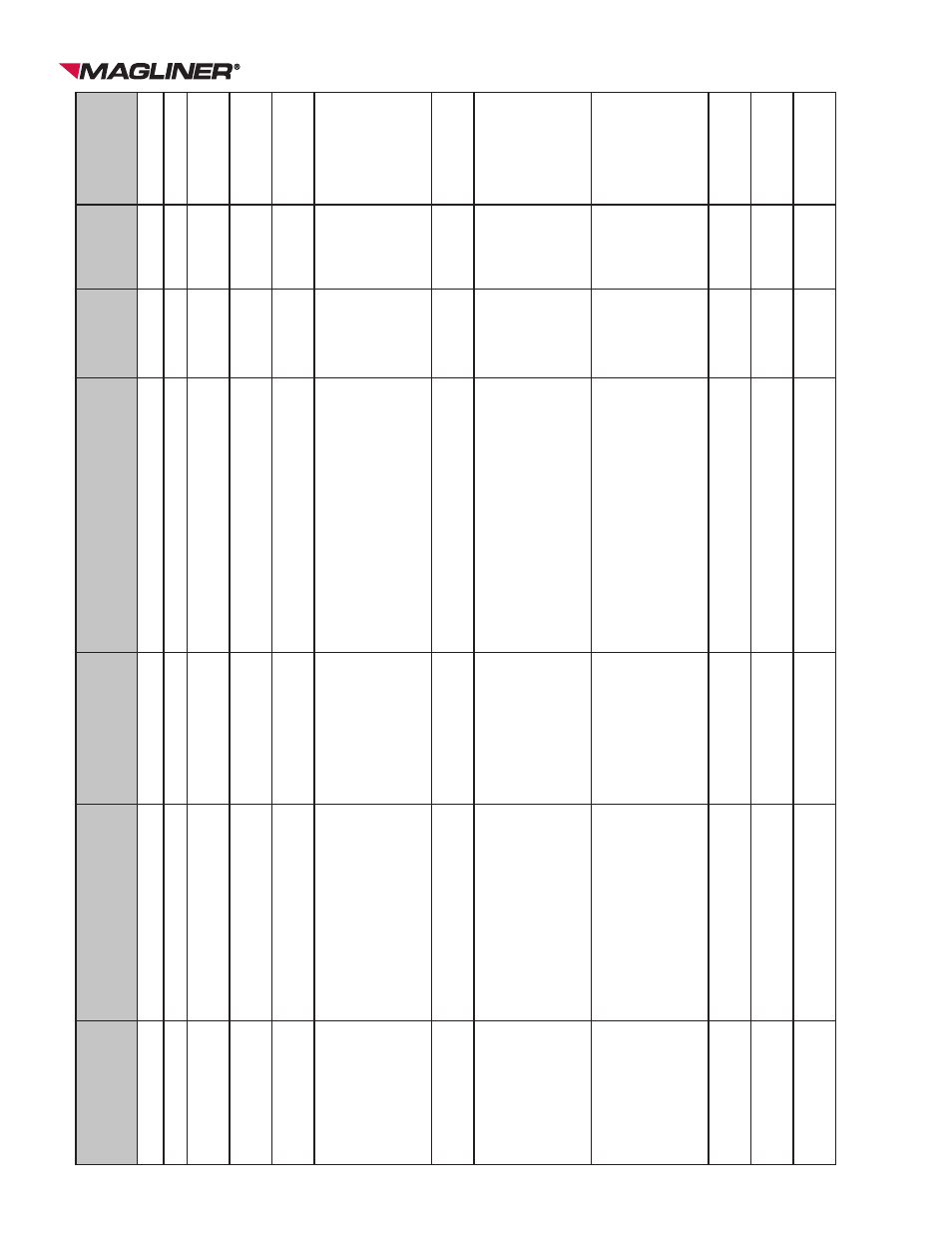

CooLift

®

Area

Description

Method of Inspection

Normal Condition

Findings Pass or

Fail

Timing

Notes

Electrical

Buttons and housing

Visual inspection

No cracks or damage

W

eekly

W

elds

No cracked welds

Visual inspection

W

elds intact, no cracks

Monthly

Brake System

Fluid level

Visual inspection

Fluid level up to notch in master cylinder reservoir

Monthly

Brake System

Hose without damage, abra

-

sion, wear

Visual inspection

No visible damage or wear

Monthly

Brake System

Brake discs have minimal rub and warp

Spin wheel

Wheel should continue to rotate several times before stopping

Monthly

Hydraulics

Fittings not leaking •

Hose fittings inside enclosure

•

Tube fittings under enclosure and in frame

•

Cylinder fittings

Wipe around fittings with dry rag

No leaks (rag remains dry)

Monthly

Hydraulics

No cracks or damage to hose or tubing

Visual inspection

No deep scratches or dents

Monthly

Hydraulics

Manual operation

Operate hydraulic pump up and down several times manually using pump handle and bypass valve

•

Deck should lift completely within 35 strokes of pump handle

•

Manual bypass valve should allow deck to descend and not leak once re-closed

Monthly

Hydraulics

Cylinder bearing cap is tight

Manual / V

isual

inspection

•

Manually attempt to turn the bear

-

ing cap

•

Inspect to determine if bearing cap is flush with top of cylinder - should not see any threads above cylinder body

Monthly

Hydraulics

Cylinder mount screws to frame and deck are tight

Manual inspection

Cylinder body is tight to frame; deck mounting screw is tight

Monthly

Hydraulics

Fluid level

Visual inspection

Fluid should be about 1/2 inch below top of reservoir when deck is down

Monthly

Suspension

Wheels and casters spin freely

Manual inspection

Wheel should continue to rotate sev

-

eral times before stopping

Monthly