Electrical supply, Verify burner components, Verify firing input range – Beckett CG50 User Manual

Page 7: Verify burner air tube assembly

7

CG15, CG25, CG50 Burner Manual

Electrical Supply

Check the nameplate on the burner to verify that the

power connections available are correct for the burner.

Refer to Figure 1. All power must be supplied through

fused disconnect switches and comply with the latest

edition of National Electric Code NFPA 70 (Canada CSA

C22.1) and all other local or applicable codes.

Verify Burner Components

Burner model can be checked from burner carton or rating

label on burner.

Flange mounting arrangement (Includes high-temperature

gasket and/or fi ber rope for pressure fi ring).

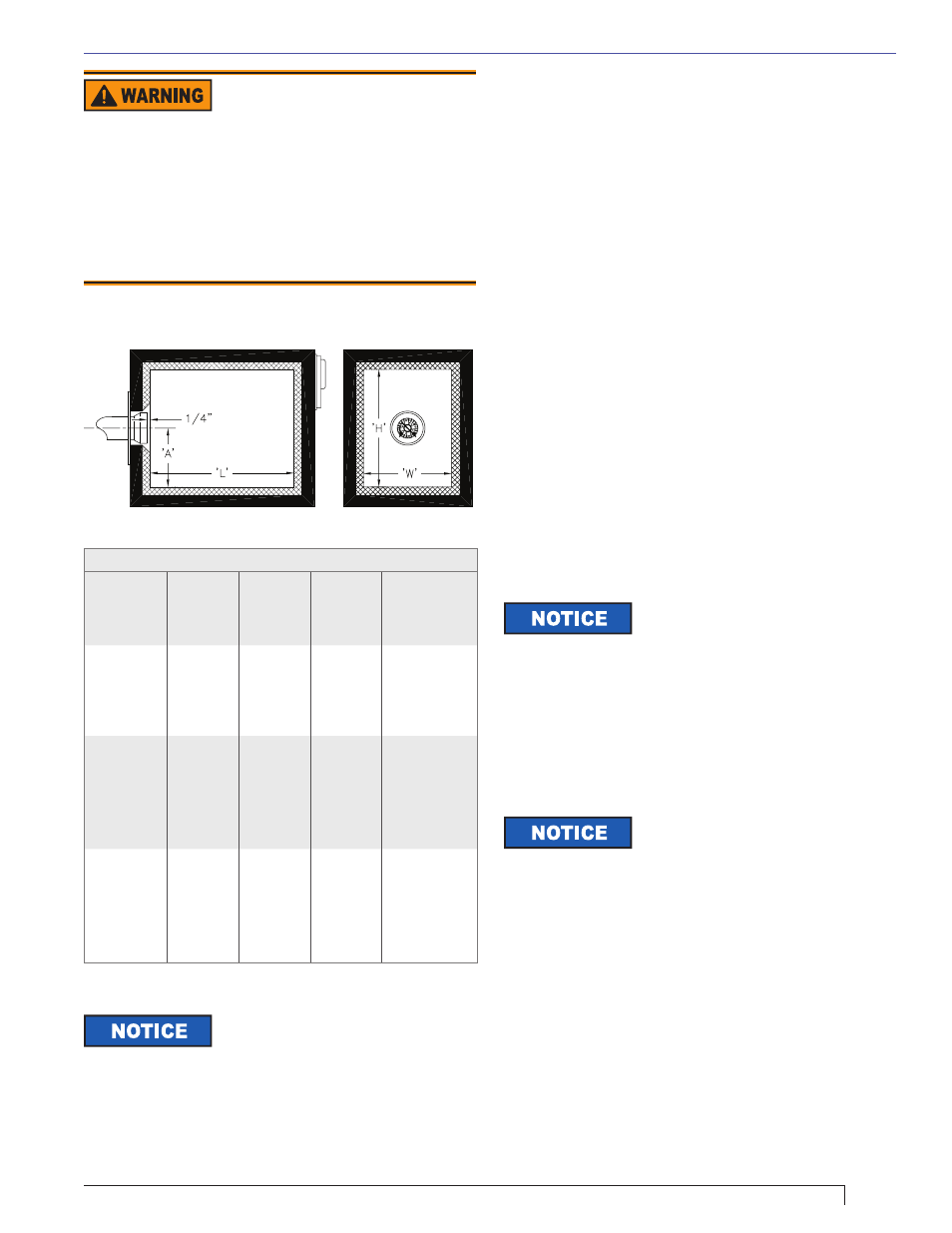

Verify Firing Input Range

Refer to appliance manufacturer’s instructions (if available)

for the fi ring input range. Otherwise the maximum

recommended fi ring range for the burner depends on the

length and width of the fi ring chamber and the distance

from the burner center to the chamber fl oor. Verify that the

chamber dimensions are at least as large as the minimum

values given in Figure 2. If the appliance dimensions are

smaller, reduce the fi ring rate accordingly.

Minimum Inside Dimensions (inches)

Burner

Model

Width

‘W’

Height

‘H’

Length

‘L’ at Min

H & W*

Burner

Head

Centerline

to fl oor ‘A’

CG15.1S

15

16

42

7

CG15.2S

16

17

45

8

CG15.3S

17

18

47

8

CG15.4S

18

19

50

9

CG25.1S

19

20

45

9

CG25.2S

20

21

48

10

CG25.3S

21

22

50

10

CG25.4S

22

23

52

11

CG25.5S

23

25

55

11

CG50.1S

21

23

55

10

CG50.2S

22

24

58

11

CG50.3S

24

26

62

12

CG50.4S

25

27

65

12

CG50.5S

27

29

70

13

Verify Burner Air Tube Assembly

The information in this section may be disregarded if

the burner supplied by the appliance manufacturer is

a matched component.

Maximum fi ring capacity depends on the furnace

pressure. Use the charts shown in Figure 3A, Figure

3B, and Figure 3C, to verify the correct burner

confi guration for the input rate.

Refer to Figures 4 & 5 to verify the air tube assembly

length and mounting insertion dimensions.

○

○

○

Figure 2 - Minimum Combustion Chamber Dimensions

Test For Gas Pipe Leaks

Leaking gas could result in asphyxiation, explosion,

or fi re hazard.

The gas supply piping must be absolutely leak-free.

Pressure test the gas piping with air that is at least

three times greater than the gas pressure being

used.

Verify that there are no leaks before proceeding.

y

y

y

Dimensions shown are for cast

iron sectional boilers with uptakes

between sections. For minimum dimensions of other

furnace types consult R. W. Beckett Corporation.

Flames are shaped by their furnaces

and by its fl ue locations. Increased

height and width can decrease the length requirement.

When shaping is too severe fl ames impinge on the walls.

Impingement causes CO and carbon deposits and may

damage the wall. Maintaining these minimum dimensions

should prevent impingement, but smaller furnaces may

be acceptable depending upon the results of applications

testing. We recommend factory testing of all new burner/

furnace combinations by the furnace manufacturer and/or

R. W. Beckett Corp.

The volume of the furnace also

infl uences the combustion process.

R. W. Beckett Corp. recommends at least 1 cubic foot of

furnace volume for each 150,000 BTU/Hr of fi ring rate.

Section: Pre-installation Checklist