Carrier Compressor and Condensing Unit User Manual

Page 5

5

Table 1 — Electrical Data — Compressor Motor With Circuit Breaker

LEGEND

*Refer to physical data table to match compressor with correct com-

pressor or water-cooled condensing unit.

NOTES:

1. Compressor MTA and RLA values are maximum figures.

2. LRA values for PW second winding =

1

/

2

the LRA – XL value.

3. 3-Pole XL circuit breakers shown, other 3-Pole XL alternates

and 6-Pole PW breakers available. Terminal lugs for circuit

breakers available in package 06EA660152 (not shown).

4. Recommended RLA value shown is determined by: circuit

breaker must trip value

÷ 1.40. Use this recommended (and

minimum) RLA value to determine nameplate stamping, mini-

mum contactor sizing, and wire sizing. RECOMMENDED RLA

FOR 06E COMPRESSORS EQUALS: MUST-TRIP (MTA) OF

CARLYLE APPROVED OVERCURRENT DEVICE BEING

USED

÷ 1.40

5. Compressor operating amps at any specific condition can only

be determined from a performance curve.

6. Ohm values for resistance are approximate and shown for ref-

erence purposes only. Motors from different vendors and

motors of different efficiencies can differ up to 15% from data

shown.

7. Electrical data for compressor part numbers 06ER, 06EM and

50 Hz models (not shown) are available from Carrier Sales

Representative.

COMPRESSOR MOTOR DATA

CIRCUIT BREAKER

Compressor

Part

Number 06E

Voltage

(3 Ph - 60 Hz)

Hp

Maximum

Must Trip

Amps

Maximum

RLA

LRA-XL

LRA-PW

(first

winding)

Motor

Winding

Resistance

(Ohms)

Recommended

Circuit Breaker

Part No.

MHA MTA LRA

Recommended

RLA

A

250

208/230

20

108

87

345

207

0.32

HH83XB336

91

104

350

74.3

575

45

36

120

72

2.2

XA461

33

38

124

27.1

460

54

44

173

104

1.3

XA424

42

49

175

35.0

265

208/230

25

140

112

446

268

0.27

HH83XC509

110

127

420

90.7

575

57

46

164

98

1.6

XA469

46

53

164

37.9

460

70

56

223

134

1.1

XA426

55

643

210

45.7

275

208/230

30

168

135

506

304

0.22

HH83XC539

142

163

507

116.4

575

65

52

176

106

1.3

XA430

50

58

168

41.4

460

84

68

253

152

0.9

XA425

63

73

210

52.1

299

208/230

40

236

189

690

414

0.15

HH83XC537

187

215

636

153.6

575

94

75

276

165

1.0

XA551

74

85

236

60.7

460

118

95

345

207

0.58

XA550

92

106

295

75.7

LRA

— Locked Rotor Amps

MHA — Must Hold Amps

MTA

— Must-Trip Amps

PW

— Part-Winding (Start)

RLA

— Rated Load Amps

XL

— Across-the-Line (Start)

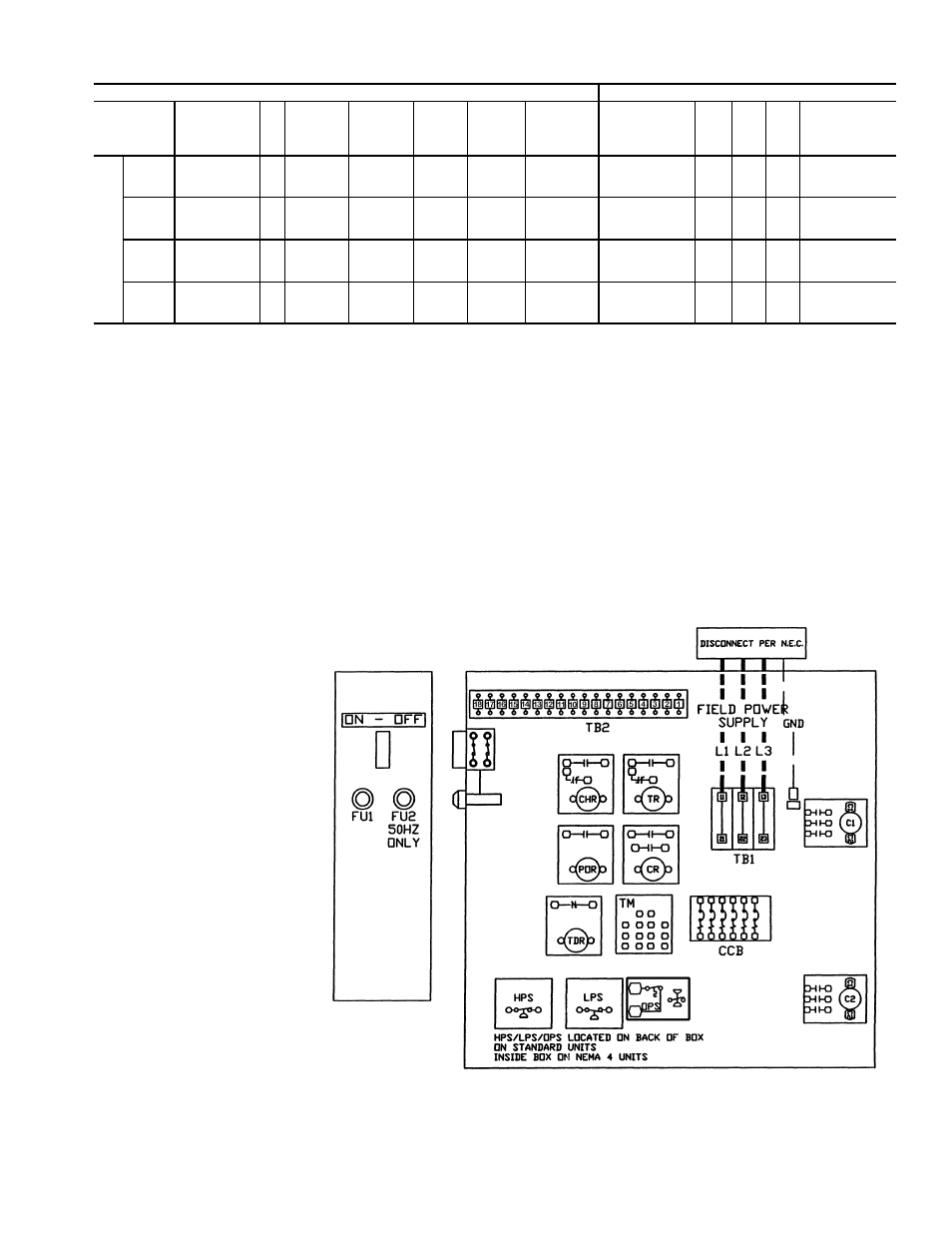

Fig. 5 — Component Location

LEGEND

C1

— Compressor Contactor

C2

— Compressor Contactor (PW)

CCB

— Compressor Circuit Breaker

CHR

— Crankcase Heater Relay

CR

— Control Relay

FU

— Fuse

GND

— Ground

HPS

— High-Pressure Switch

LPS

— Low-Pressure Switch

NEC

— National Electrical Code

NEMA — National Electrical

Manufacturer’s Association

OPS

— Oil Pressure Switch

POR

— Pumpout Relay

TB

— Terminal Block

TDR

— Time Delay Relay

TM

— Timer Motor

TR

— Timer Relay