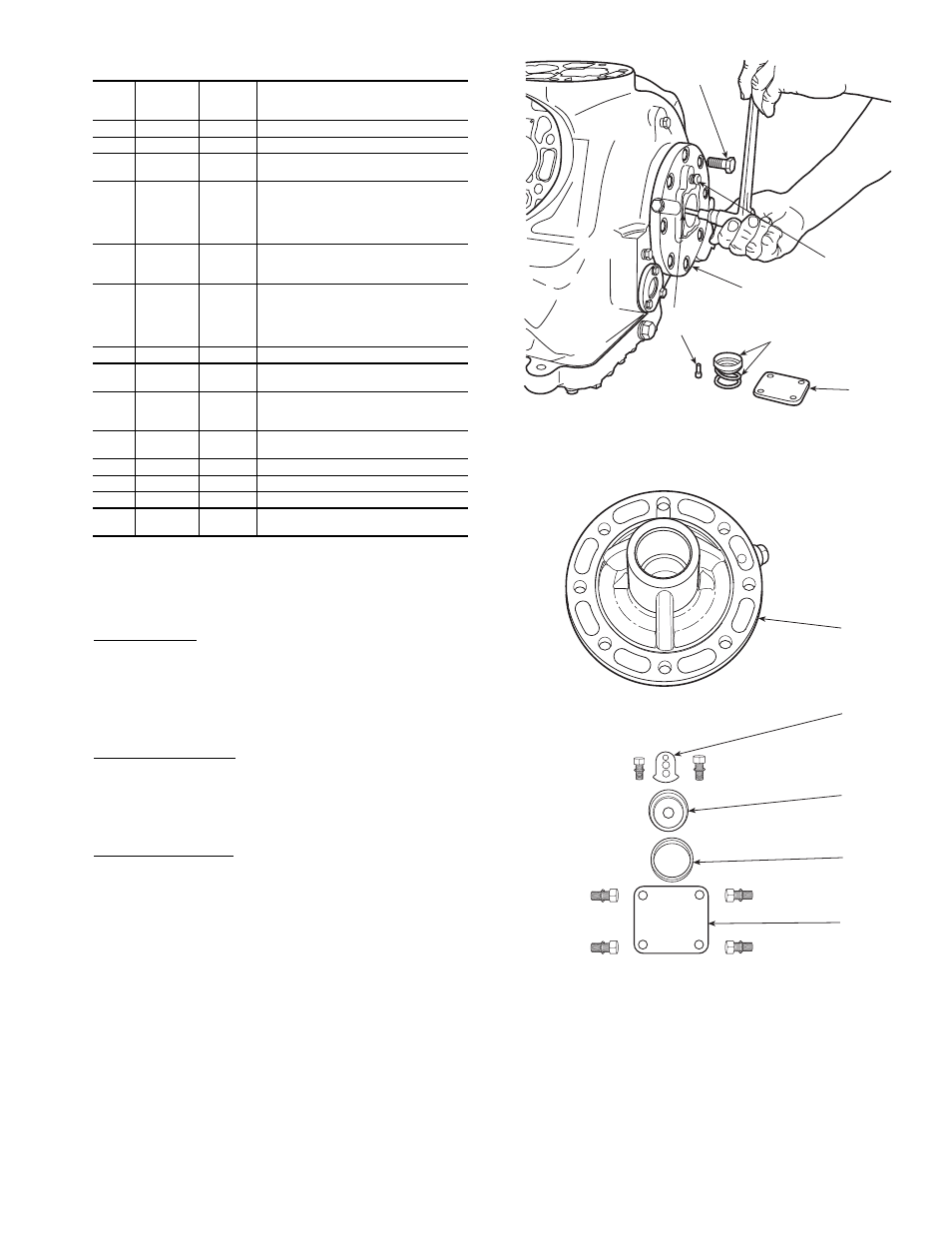

Lubrication system, 13 table 6 — torque values, Fig. 12 — removing pump end bearing head – Carrier Compressor and Condensing Unit User Manual

Page 13: Fig. 13 — pump end bearing head assembly

13

Table 6 — Torque Values

Lubrication System

TESTING OIL PUMP — An oil pressure tap is located above

oil pump cover plate (Fig. 12). Oil pressure should be 12 to

18 psi above suction pressure.

Oil Filter Screen — Screen is accessible through bottom cover

plate. Remove and inspect strainer for holes and dirt. Clean it

with solvent and replace.

OIL PUMP AND BEARING HEAD — The oil pump assem-

bly is contained in the pump end bearing head aluminum

casting. (The pump end main bearing is a machined part of this

casing — no insert bearing.)

Remove Bearing Head — Remove bearing head from crank-

case and disassemble oil pump. Drive segment cap screws

must be removed before bearing head can be removed

(Fig. 12). Remove pump vane assemblies from both sides of

the bearing head by pushing against the bearing side of the

rotor. Check all parts (Fig. 13) for wear and damage.

Replace Bearing Head

1. Install the rotor retaining ring in the ring groove of the

pump rotor with chamfered edge toward compressor.

Compress retaining ring, and insert pump rotor into

bearing head.

2. Place the pump vanes, pump vane spring with guides, and

snap rings into the bearing head. Compress the springs

and force the snap rings into their grooves. (Insert snap

rings with flat side against casting.)

3. Bolt bearing head to crankcase (use 55 to 65 lb-ft torque).

Bolt drive segment to crankshaft.

4. Insert the oil feed guide vane with large diameter inward.

Place oil feed guide vane spring over small diameter of

guide vane.

5. Install pump cover plate.

SIZE

DIAM

(in.)

THREADS

PER IN.

TORQUE

RANGE

(lb-ft)

USAGE

1

/

16

27 (pipe)

8-12

Pipe Plug — Crankshaft

1

/

4

18 (pipe)

20-25

Pipe Plug — Crankcase

1

/

4

20

8-10

Conn. Rod Cap Screw

8-12

Junction Box

1

/

4

28

3-5

Sight Glass

14-18

Oil Pump Drive Segment

14-18

Unloader Valve

14-18

Discharge Valve Stop

12-15

Head Gasket Positioning Screw

5

/

16

18 (pipe)

15-24

Cover Plate — Pump End Bearing

Head

15-24

Discharge Service Valve (4 cyl)

3

/

8

16

30-40

Bottom Plate — Crankcase

30-40

Compressor Foot

30-40

Terminal Plate

25-30

Oil Plug — Pump End Bearing Head

2-4

Terminal Bolts

3

/

8

18 (pipe)

30-40

Pipe Plug — Junction Box

7

/

16

14

55-65

Motor End Cover

55-65

Pump End Bearing Head

1

/

2

13

90-100

Cylinder Head

90-120

Discharge Service Valve (6 cyl)

90-120

Suction Service Valve (4 cyl)

5

/

8

11

90-120

Suction Service Valve (6 cyl)

90-120

Rotor Lock — Crankshaft

5

/

8

18

60-75

Oil Drain Plug

3

/

4

16

105

Stator Lock

No. 6

32

1-2

Check Valve Body — Crankcase

No. 10

32

4-6

Oil Pump Drive Segment

4-6

Terminal Screw

1

2

3

4

5

REMOVE 8 CAP

SCREWS

DRIVE SEGMENT

CAP SCREWS

OIL FEED GUIDE VANE

AND SPRING

OIL

PRESSURE

TAP

PUMP END

BEARING HEAD

COVER

PLATE

Fig. 12 — Removing Pump End Bearing Head

LEGEND

Fig. 13 — Pump End Bearing Head Assembly

1

— Pump End Bearing Head

2

— Drive Segment

3

— Oil Feed Guide Vane

4

— Oil Feed Guide Vane Spring

5

— Cover Plate