Compressor running gear replacement – Carrier Compressor and Condensing Unit User Manual

Page 15

15

CRANKSHAFT — Remove pump end bearing head and

rotor. If connecting rod and piston assemblies are still in place.

remove connecting rod caps and push piston assembly up into

cylinder for crankshaft clearance. Pull crankshaft out through

pump end opening. Inspect crankshaft journals for wear and

tolerances shown in Table 7. Check oil passages and clean if

clogged.

PUMP END MAIN BEARING — This bearing is a machined

part of the oil pump and bearing head casting. Disassemble

bearing head. If bearing is scored or worn, replace the complete

bearing head.

CRANKCASE AND MOTOR END MAIN BEAR-

INGS — These bearings are not field replaceable. If bearings

are worn or damaged, replace compressor.

Table 7 — Wear Limits — 06E Compressor

*Maximum allowable wear above maximum or below minimum factory

tolerances shown. For example: difference between main bearing diam-

eter and journal diameter is .0035 in. (1.8760 – 1.8725) per factory tol-

erances. Maximum allowable difference is .0045 in. (.0035 + .001).

Compressor Running Gear Replacement

CRANKSHAFT — Be sure compressor end bearing washer is

in place on dowel pin. Install crankshaft through pump end,

carefully guiding it through main bearings. Replace rotor.

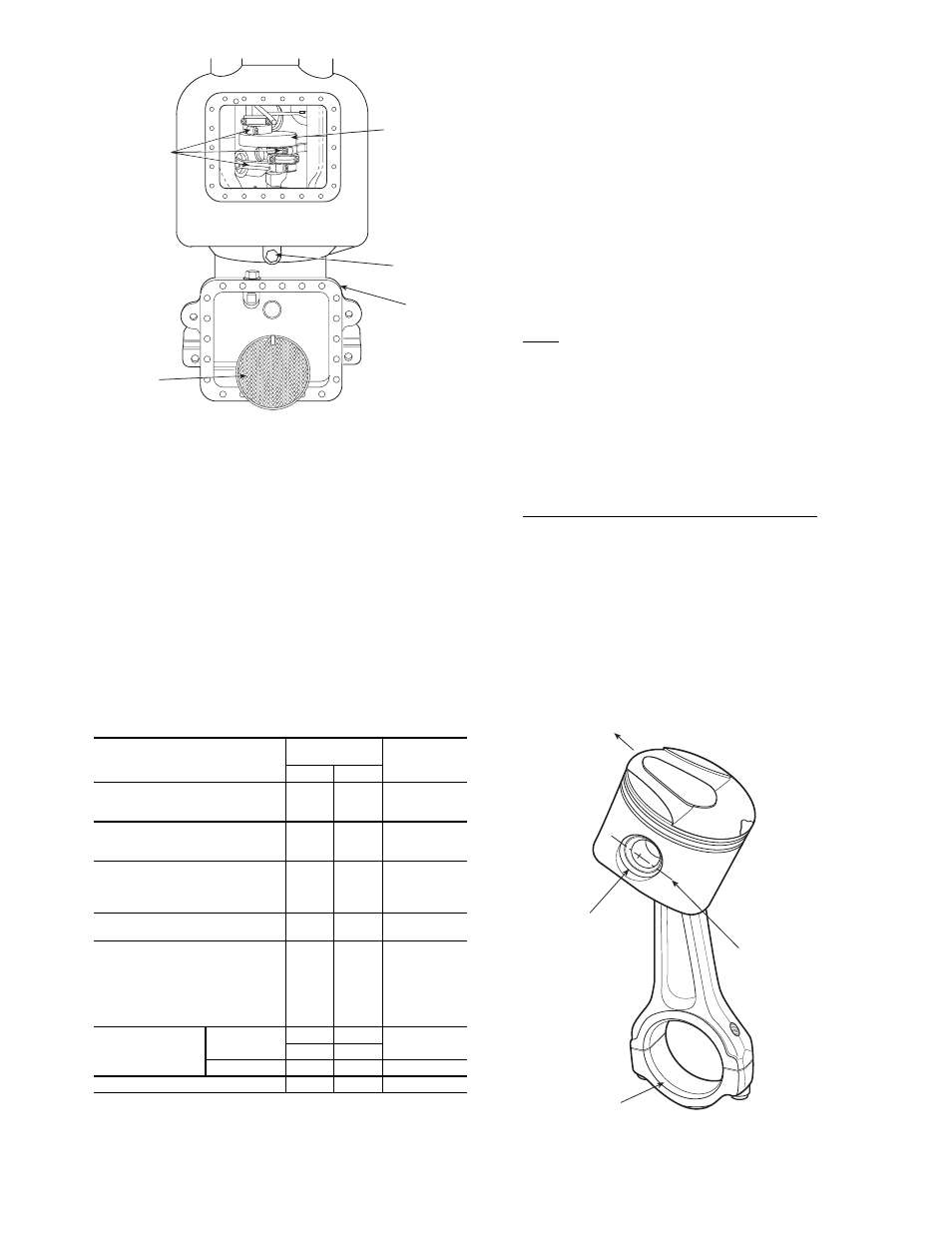

CONNECTING ROD/PISTON ASSEMBLY (Fig. 18) — The

assembly of the connecting rod with contoured-crown piston

must be as shown. Note the relationship of the piston crown

pattern with the chamfered side of the rod bearing. This ensures

that the rods in the outer positions on crankpins have the

chamfers toward crankpin fillets. On 6-cylinder compressors,

the position of the chamfer of center rod on crankpin has no

significance.

Lock the piston pin in place with retaining rings as shown in

Fig. 18.

The retaining rings should be tight enough that they cannot

be rotated by finger pressure.

Rings

1. Check ring gap by inserting each ring separately in cylin-

der approximately

3

/

8

in. from top. Ring gap should be

between 0.002 in. and 0.007 inch.

2. Install compression ring in top piston groove with either

side up (no difference). Install oil ring below compression

ring with notched end on bottom. Stagger ring gaps

180 degrees.

3. Measure side clearance between ring and piston

(Table 6). Check rings for free action.

Installation of Connecting Rod/Piston Assembly — Insert the

connecting rod/piston assemblies into cylinders with pistons

positioned as shown in Fig. 18 and 19.

This is necessary so that the suction valve and backer lie

properly over the contoured piston crown.

Be sure that the outer rod on each crankpin has the

chamfered side toward the crankpin fillet (this is a double

check on the connecting rod/piston assembly).

Install caps to matching connecting rods with chamfered

sides aligned. Caps are secured with Nylock cap screws.

Tighten with 8 to 10 lb-ft torque.

COMPRESSOR PART

FACTORY TOL.

(in.)

MAXIMUM

ALLOWABLE

WEAR* (in.)

Max

Min

MOTOR END

Main Bearing Diameter

1.8760

—

0.001*

Journal Diameter

—

1.8725

PUMP END

Main Bearing Diameter

1.6260

—

0.001*

Journal Diameter

—

1.6233

CONNECTING ROD

Bearing Diameter

(After Assembly)

1.7515

—

0.002*

Crankpin Diameter

—

1.7483

THRUSTWASHER

(Thickness)

—

0.155

—

CYLINDERS

Bore

2.6885

—

0.002

Piston Diameter

—

2.6817

0.002

Wrist Pin Diameter

—

0.8748

0.001

Con. Rod Wrist Pin ID

0.8755

—

0.001

Piston Ring End Gap

0.007

0.002

0.015

Piston Ring Side Clearance

0.003

0.001

0.002

VALVE

THICKNESS

Suction

0.0315

0.0305

0.002

0.0255

0.0245

Discharge

0.0225

0.0215

0.002

END CLEARANCE

0.031

—

0.010

CONNECTING

RODS AND

CAPS

CRANKSHAFT

OIL DRAIN

PLUG

(MAGNETIC)

BOTTOM

COVER

PLATE

OIL FILTER

SCREEN

Fig. 17 — View with Bottom Cover Plate Removed

RETAINING

RING GROOVE

(BOTH SIDES)

CHAMFER MUST

BE ON THIS SIDE

POSITION RETAINING

RING GAP APPROXIMATELY

ON THIS CENTERLINE

TOWARD SUCTION VALVE

DOWELS IN CYLINDER DECK

Fig. 18 — Connecting Rod/Piston Assembly