Belt Drives EVB-2S User Manual

Page 3

Freeze sealed bearing and re-heat area around bearing housing, the bearing should fall

into place without a problem. Replace retaining ring.

4. Make sure motor & transmission shafts are square with each other. (Refer to section)

1990-up models only.

This procedure is necessary so that the hub and mainshaft will fit together properly and will not let the mainshaft

spin inside of our hub. (This procedure is not necessary on taper shaft models 1986-89)

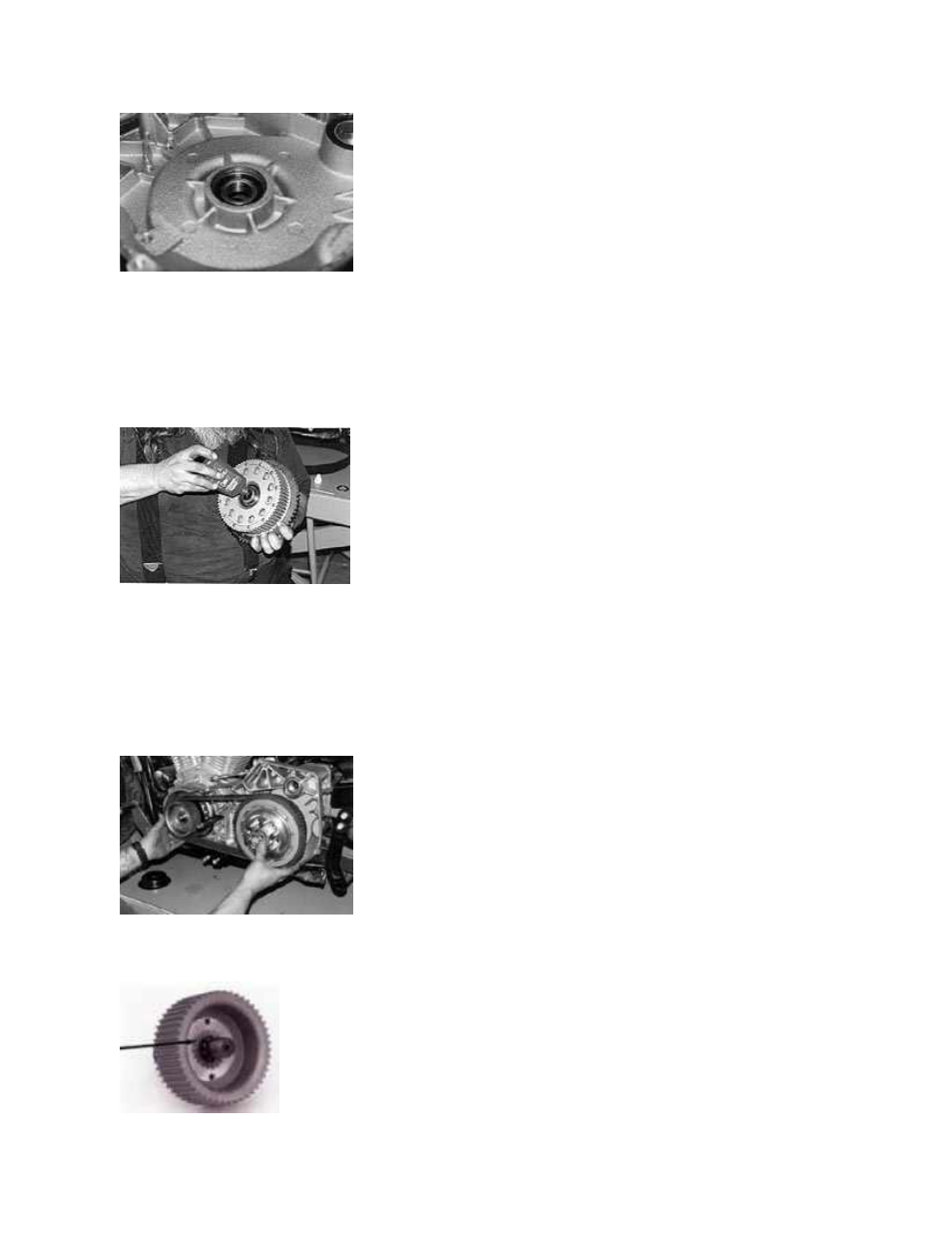

6. If front pulley shimming was necessary be sure that the shims are in place, now install rear pulley, belt and

front pulley at the same time. (Fig. 6)

Fig. 6 Install both pulleys and belt at the same time.

Engine shaft spline should not protrude from pulley. (Fig. 7)

Fig. 7 If engine shaft spline protrudes as pictured, a washer is needed to compensate for protrusion

of spline before washer and nut is installed.

3

Clean mainshaft spline area so that there is no oil residue to interfere with the

Loctite® bonding.

5. For spline mainshaft models, 1990-up, apply red

Loctite® into the back side of our hub inside of the spline and

let the

Loctite® flow onto the mainshaft when sliding the rear basket assembly on. (Fig. 5)

Fig. 5 Apply red

Loctite® to spline hub before installing it onto mainshaft. This is for

Failure to Loctite

® the splined hub properly will cause the splines to wash out.