Trouble- shooting guide, Error codes, Interpreting the codes – Wilbur Curtis TLP61 User Manual

Page 9

9

Error Codes are reset by turning the rear toggle switch to Standby for a minimum of 10 seconds, then returning

the switch to ON. Any service required for your Curtis system must be performed by a qualified service

technician.

TROUBLE-

SHOOTING

GUIDE

ERROR CODES

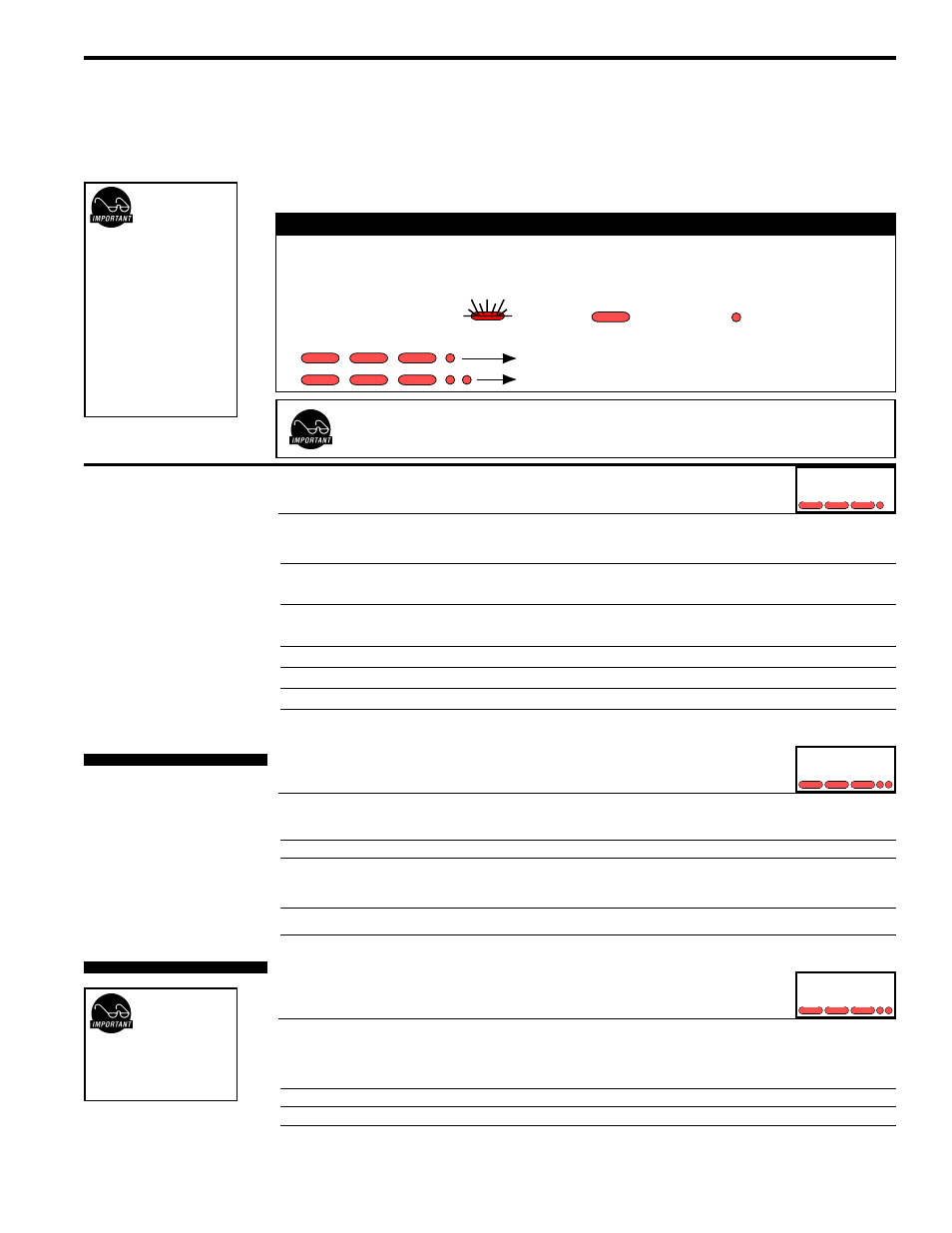

Curtis ADS Systems contain various safety features in the electronic circuitry that will

shut down the functions of the unit in the event of systems faiolures. Error codes are

signalled by the red READY-TO-BREW light blinking.

INTERPRETING THE CODES

ADS technology features a state-of-the-art error code system. This is designed to quickly advise you of any problems the

system may experience expediting service or repair. Occasionally, an error reported may be a problem with the water

supply or electrical power; NOT directly associated with a fault of the Curtis system itself. An example of this includes a

clogged water filter — indicated by a water level error code.

Error Codes are indicated by

blinking.

= Long Flash

= Short Flash

The code pattern is as follows:

WATER LEVEL PROBLEM

TEMPERATURE PROBLEM

READY TO BREW

1. Water line has been turned OFF

2. Insufficient Water Supply;

Water Line Pinched

3. Clogged Water Filter

4. Defective Inlet Valve

5. Grounded Probe

6. Defective Control Board

Turn ON Water Line; confirm unit is turned on

and water is flowing into heating tank.

Straighten Wafer Line; confirm unit is turned on

and water is flowing into heating tank.

Replace filter; confirm unit is turned on and water

is flowing into heating tank.

Contact Factory.

Contact Factory.

Contact Factory.

SYMPTOM:

SYMPTOM:

SYMPTOM:

SYMPTOM:

SYMPTOM: W

W

W

W

WAAAAATER DOES NOT FLOW INTO HEA

TER DOES NOT FLOW INTO HEA

TER DOES NOT FLOW INTO HEA

TER DOES NOT FLOW INTO HEA

TER DOES NOT FLOW INTO HEATING

TING

TING

TING

TING TTTTTANK

ANK

ANK

ANK

ANK

POSSIBLE CAUSE

SOLUTION

Water Level

ERROR CODE

SYMPTOM:

SYMPTOM:

SYMPTOM:

SYMPTOM:

SYMPTOM: W

W

W

W

WAAAAATER HEA

TER HEA

TER HEA

TER HEA

TER HEATING

TING

TING

TING

TING TTTTTANK OVERFLOWING

ANK OVERFLOWING

ANK OVERFLOWING

ANK OVERFLOWING

ANK OVERFLOWING

POSSIBLE CAUSE

SOLUTION

Water Level

ERROR CODE

7. Defective Water Inlet Valve

8. Limed-Up Probe

9. Non-grounded or loose terminal

connections at control board or

tank.

10. Defective Control Board.

Turn power off and observe tank water level. If water continues to

flow Inlet Valve must be cleaned, rebuilt or replaced.

Clean and/or replace.

The control board must be securely grounded for proper operation.

Check for loose connections at the terminals.

Contact Factory

SYMPTOM:

SYMPTOM:

SYMPTOM:

SYMPTOM:

SYMPTOM: W

W

W

W

WAAAAATER IN HEA

TER IN HEA

TER IN HEA

TER IN HEA

TER IN HEATING

TING

TING

TING

TING TTTTTANK DOES NOT GET HOT

ANK DOES NOT GET HOT

ANK DOES NOT GET HOT

ANK DOES NOT GET HOT

ANK DOES NOT GET HOT;;;;;

W

W

W

W

WAAAAATER

TER

TER

TER

TER TEMPERA

TEMPERA

TEMPERA

TEMPERA

TEMPERATURE LOW

TURE LOW

TURE LOW

TURE LOW

TURE LOW

POSSIBLE CAUSE

SOLUTION

11. Defective or Loose Heat Sensor

12. Defective Heating Element

13. Defective Control Board

Make sure there is a layer of silicone paste (Part No WC-5231)

between the sensor and tank body. The fastening nut should be

securely tightened, making a good connection. Check wire for

damage.

Contact factory.

Contact factory.

Temp Sensor

ERROR CODE

IMPOR

IMPOR

IMPOR

IMPOR

IMPORTTTTTANT

ANT

ANT

ANT

ANT:::::

Error codes are

indicated by the

red READY TO

BREW light. If and

Error Code occurs,

the unit will shut

down all functions

including heating,

water inlet, water

delivery.

ALWAYS

confirm Error

Code three times.

IMPORTANT:

Heating function

may be SHUT

DOWN due to

Water Level Error

Code.

ADS ERROR CODES

ADS ERROR CODES

ADS ERROR CODES

ADS ERROR CODES

ADS ERROR CODES