Nut and cap screw torque, Table ii. vibrator nut and cap screw, Torque requirements – Metalfab Martin Motomagnetic Electric Vibrator User Manual

Page 12: Connecting power to vibrator, Table iii. vibrators and wiring diagrams, Warning, Installation

Martin Engineering M3286-8/01

8

MOTOMAGNETIC

®

Electric Vibrators

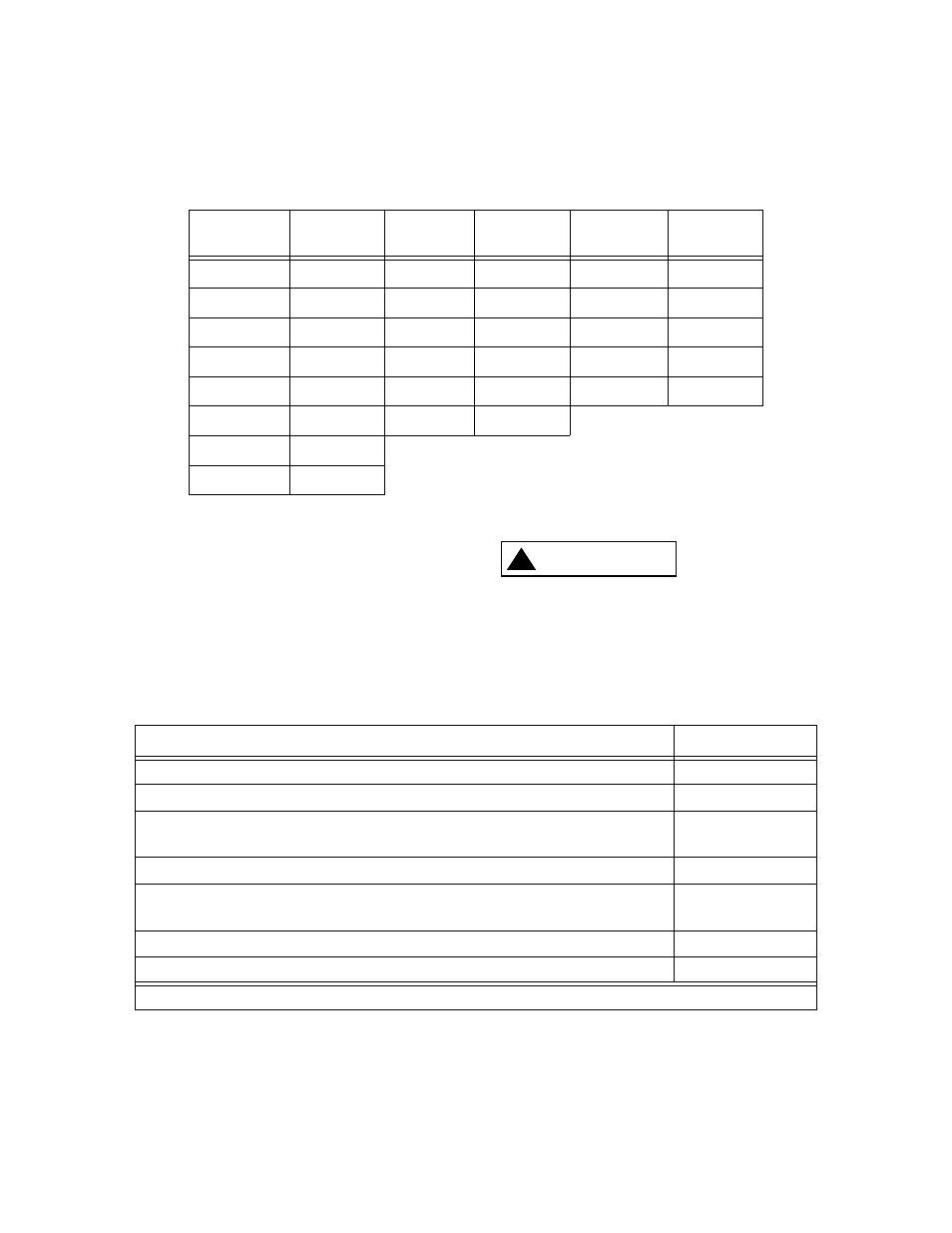

Nut and cap screw

torque

After removing any nuts or cap screws from vibrator assembly, re-install to

the torque values specified in Table II.

Table II. Vibrator Nut and Cap Screw

Torque Requirements

Connecting power

to vibrator

WARNING

!

Wire vibrator in accordance with National Electrical Code

Article 430. Have wiring installed by a qualified electrician

only.

1. Find wiring diagram number for your vibrator on vibrator nameplate, or

see Table III.

Table III. Vibrators and Wiring Diagrams

Cap Screws

ft/lb (kgm)

Shaft Nuts

ft/lb (kgm)

Terminal

Block Nuts

ft/lb (kgm)

M6

7 (1)

M13x1

22 (3)

M4

0.87 (0.12)

M8

16.5 (2.3)

M15x1

36 (5)

M5

1.45 (0.20)

M10

35 (4.8)

M20x1

72 (10)

M6

2.17 (0.30)

M12

58 (8)

M25x1.5

123 (17)

M8

4.70 (0.65)

M14

94 (13)

M30x1.5

246 (34)

M10

9.80 (1.35)

M16

137 (19)

M45x1.5

360 (50)

M18

195 (27)

M20

275 (38)

Frame Size*

Wiring Diagrams

00 through 01, single-phase, 3600 rpm

Diagram 1A

10 through 30, singe-phase, 3600 rpm

Diagram 1E

00 through 70, three-phase, 1200, 1800, and 3600 rpm; CD9-570;

and 575-volt 900 rpm

Diagram 2A

40 through 70, three-phase, 900 rpm except 575V

Diagram 2C

80 through 110, three-phase, 1200, 1800, and 3600 rpm; and 575V

900 rpm

Diagram 5A

80 through 110, three-phase, 900 rpm except 575V

Diagram 5B

CDX models

CDX 6- or 9-Lead

*See “Part Numbers” section for specific model numbers.

Installation