Periodic maintenance, Procedure, Daily weekly monthly – B&C Technologies IP Series Commercial Ironer User Manual

Page 24

Periodic Maintenance

Procedure

24

Daily

Weekly

Monthly

Inspect the temperature pick up sled and

the cylinder. Remove debris if present.

Make sure the temperature pick up sled is in

full contact with the ironing cylinder.

At shut down, wipe machine down with a

mild cleaning agent and vacuum or sweep

up any lint that has accumulated. Lint is

highly flammable!

Inspect safety labels and replace any that

are damaged, worn, or illegible.

Inspect the guide ribbons (guide tape) for

damaged or missing ribbons. Replace as

necessary.

Inspect feed belts for proper tension. There

should be no slippage as the ironer runs.

Do not over tighten the feed belts, as this

will cause premature wear.

Inspect the return belts for proper tension.

Return belts tend to elongate after initial

startup and wear in.

Inspect the drive chain and gears.

Inspect the compression roll and ensure that

the pressure is correct. The compression

roll should only slightly touch the ironing

cylinder and not exert too much pressure.

For steam models, inspect the rotary steam

joint for leaks. If a leak is noted, a repair kit

is available. Contact B&C Technologies for

information.

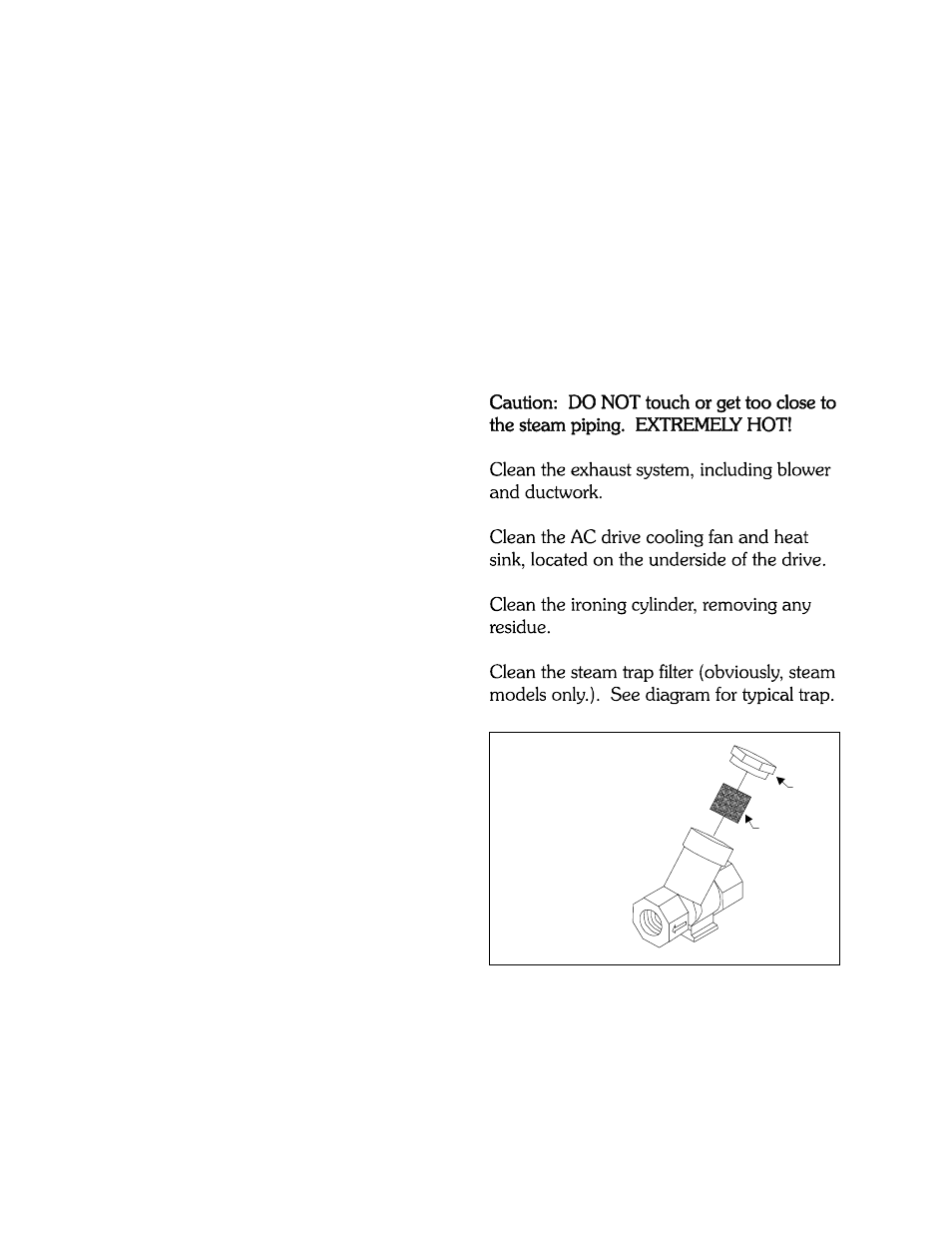

NUT

ELEMENT

1. Turn off steam supply and allow time

for the valve to cool if necessary.

2. Unscrew nut.

3. Remove element and clean.

4. Replace element and nut.

Grease all bearings with high temperature

grease. DO NOT mix different grease types.

Grease the motor chain and sprockets.