Tjernlund SS1 SideShot (Discontinued Version - Pre UC1 Universal Control) 8504041 Rev A 11/99 User Manual

Page 5

The following steps should be followed in making the safety inspection:

1. Conduct a gas leakage test of the appliance piping and control system downstream of the shutoff valve in the supply line to the

appliance.

2. Visually inspect the venting system and determine there is no blockage or restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition.

3. Shut off all gas to the appliance(s).

4. Inspect burners and crossovers for blockage and corrosion.

5. Applicable only to furnaces: Inspect heat exchanger for cracks, openings or excessive corrosion. Check both the limit control

and fan control for proper operation.

6. Applicable only to boilers: Inspect for evidence of water or combustion product leaks. Determine that the water pumps are in

operating condition. Test low water cutoffs, automatic feed controls, pressure and temperature limit controls and relief valves in

accordance with the manufacturer's recommendations to determine that they are in operating order.

* Excerpts from the National Fuel Gas Code (ANSI Z223.1/NFPA #54), Appendix H.

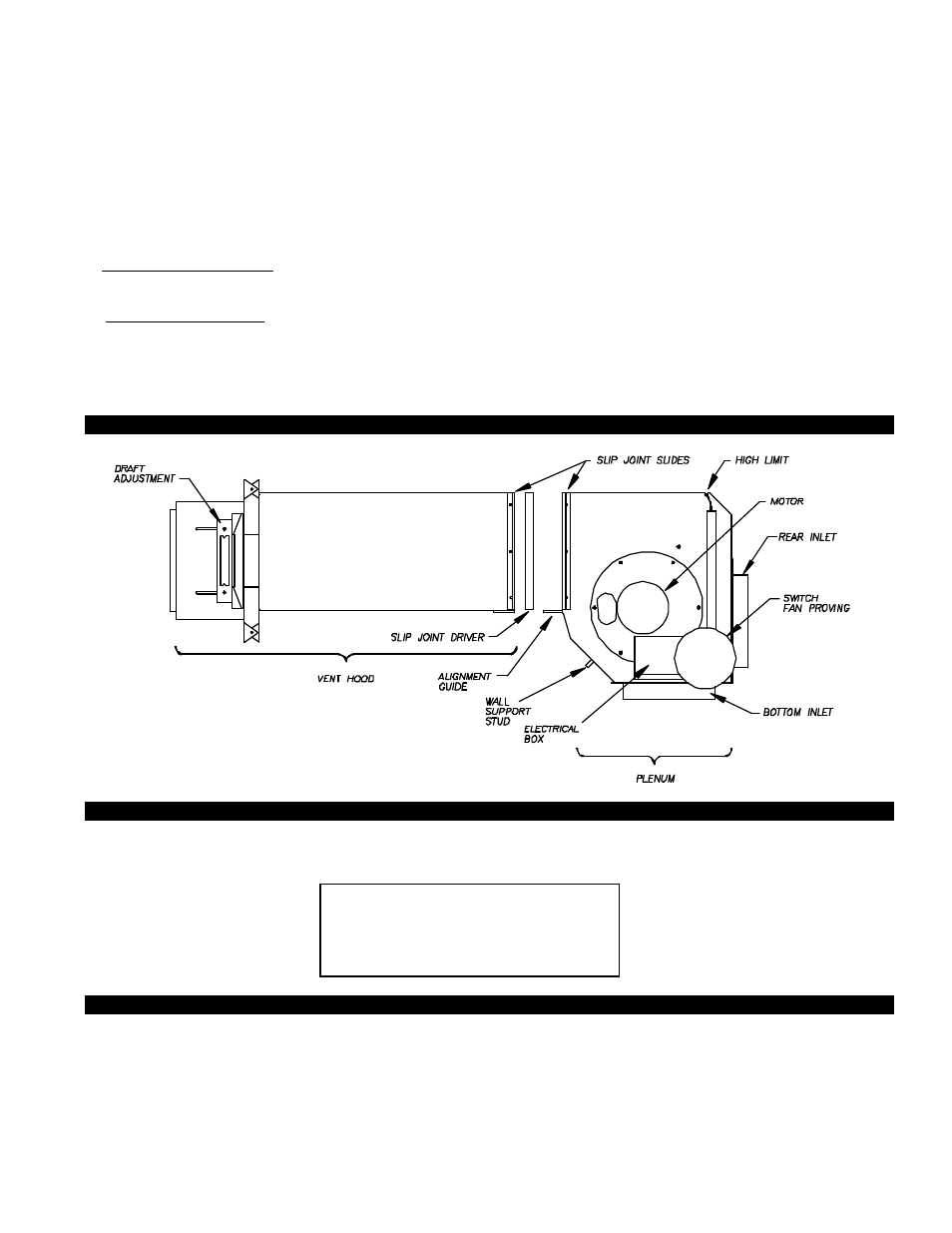

SIDESHOT TERMINOLOGY

PLENUM AND VENT HOOD CLEARANCE FROM COMBUSTIBLES

With an inlet flue gas temperature of 650oF or below, the SideShot has been Listed for the following clearances from combustible

materials:

VENT HOOD TERMINATION CLEARANCES

The SideShot has been ETL Listed according to the requirements of the National Fire Protection Association #31, #54 and #211

as follows, (See Diagram A, Page 5):

• The exit terminals of mechanical draft systems shall not be less than 7 feet above grade when located adjacent to public walk

ways.

• A venting system shall terminate at least 3 feet above any forced air inlet located within 10 feet.

4

IMPORTANT

Vent Hood and top of Plenum: Zero Clearance

Plenum front and sides: 1/2 inch

Plenum rear: 3 inches