Tjernlund SS1 SideShot (Discontinued Version - Pre UC1 Universal Control) 8504041 Rev A 11/99 User Manual

Page 10

b)

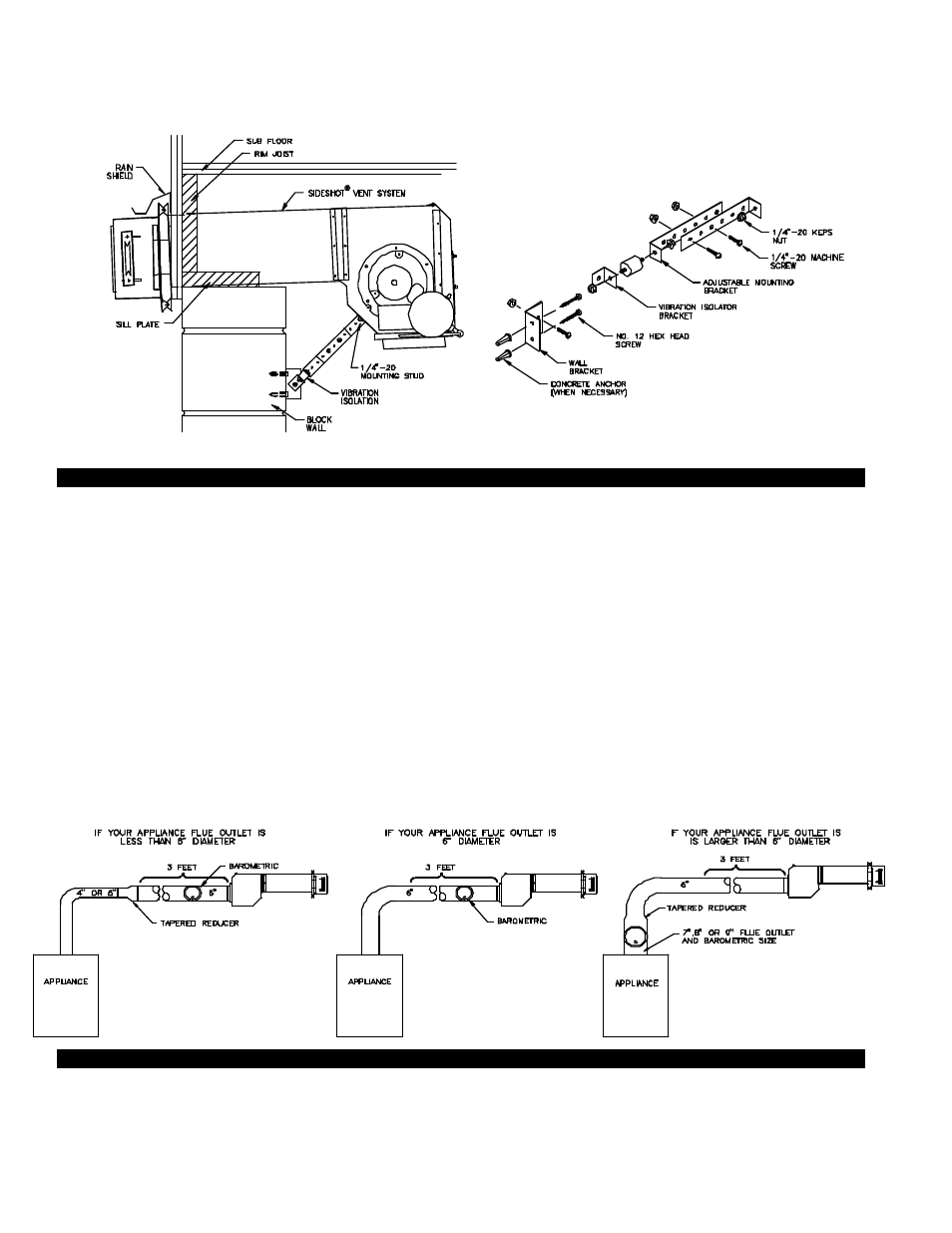

If installing the bracket into a masonry wall, drill 2 holes at each point established in step 3 with a 1/4" masonry drill bit

approximately 1" deep. Tap the masonry anchors into the holes drilled in step 4. Screw the wall bracket onto the wall.

5. Connect the other end of wall support bracket to the stud on the plenum using the supplied 1/4"-20 keps nut. (See Diagram J).

INSTALLATION OF VENT PIPE

If installing the SideShot Vent System on an oil or gas appliance which is not equipped with a draft hood or draft diverter, a baro-

metric draft control must be used. Install the barometric draft control as shown, (See Diagram K). The SideShot Vent System is

designed to accept all brands of 6" single wall, Type "B", Class "A" or Type "L" vent pipe. The vent pipe used must be in compli-

ance with local codes and the listing of the vent pipe manufacturer. When necessary, install tapered reducers and increasers as

shown below.

Determine which inlet of the SideShot Vent System will allow for the least amount of elbows to the appliance. DO NOT USE

BOTH INLETS. Calculate the equivalent vent pipe footage from the appliance to the SideShot Vent System by adding the straight

vent pipe length and the equivalent elbow lengths together. Each 90 degree elbow is equal to 10 feet of straight vent pipe, each

45 degree elbow is equal to 5 feet of straight pipe. The equivalent vent pipe length must not exceed 50 feet from the appliance to

the SideShot Vent System. Vent runs of over 15 linear feet should use an approved, insulated vent connector to prevent problems

related to sulfur condensation. It is not necessary to maintain a 1/4" rise per every foot of horizontal when Side Wall Venting.

The SideShot Vent System is shipped from the factory with the plug connected to the rear and the vent pipe inlet collar connected

to the bottom. If using the bottom inlet, skip to the section entitled "Vent Pipe Clamp Assembly". If your installation requires the

use of the rear inlet, follow the steps in the section entitled "Vent Pipe Inlet Collar Conversion" to move the vent pipe inlet collar

from the bottom to the rear.

VENT PIPE INLET COLLAR CONVERSION

1. Remove the plug from rear inlet port by unfastening the 6 nuts that secure it to the Plenum. Keep the plug & nuts for later use.

2. Remove the sensing tube from the Fan Proving Switch by loosening the plastic compression fitting.

3. Remove the vent pipe inlet collar from the bottom port by unfastening the 6 nuts. Keep the nuts for later use.

9

DIAGRAM K

DIAGRAM J