Tjernlund SS1 SideShot (Discontinued Version - Pre UC1 Universal Control) 8504041 Rev A 11/99 User Manual

Page 22

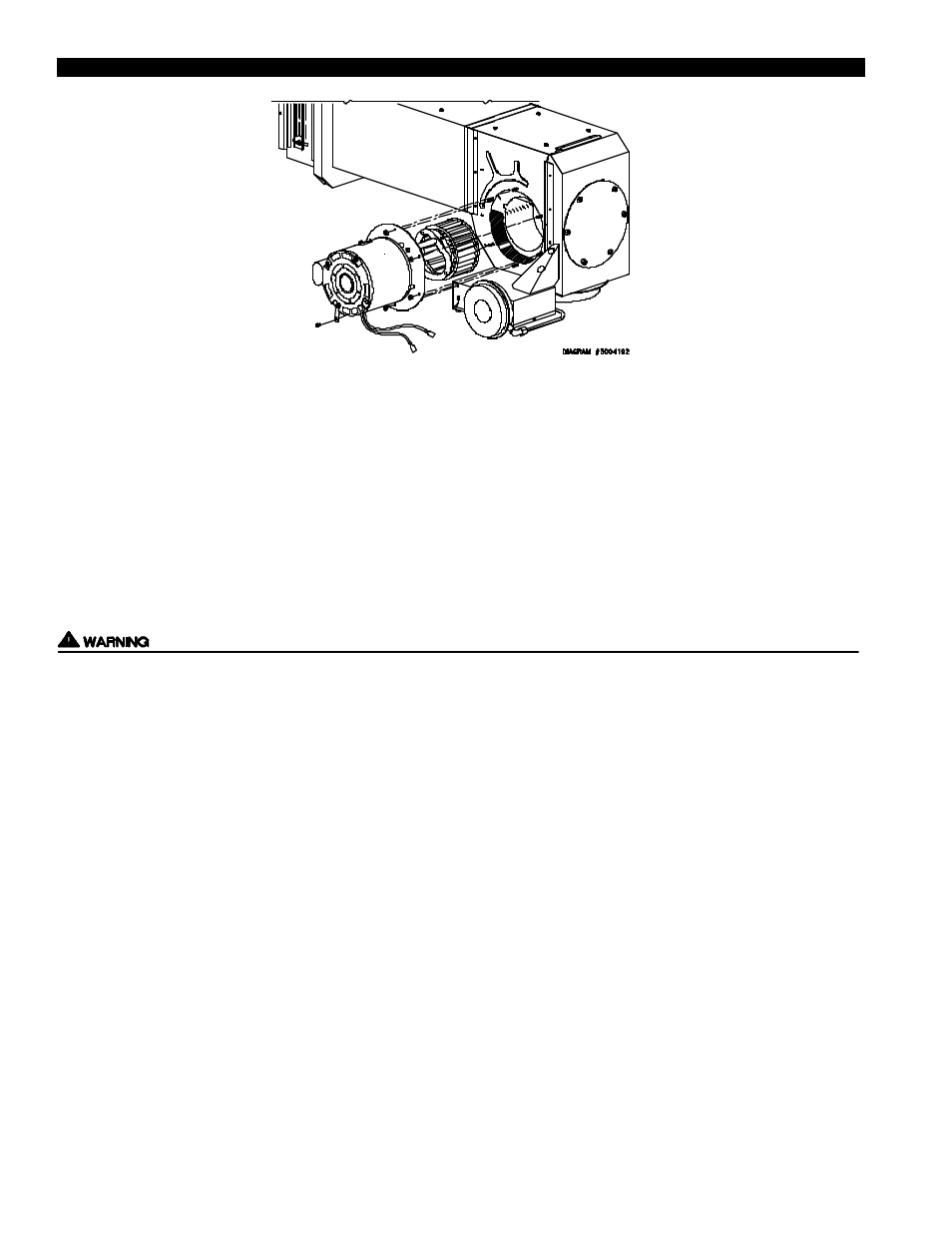

WHEEL INSPECTION (DIAGRAM N)

1. The SideShot blower wheel must be inspected annually. Particulates, such as soot, oil impurities and sheet rock dust, can

prevent proper venting and will cause noise and vibration. Follow instructions, below for motor/wheel assembly removal.

2. Clean all particulate from wheel with a soft metal wire brush and soot cleaner. Clean the pocket of each blade, as well as the

rest of the wheel.

3. A wheel that exhibits large amounts of particulate or appears to be out of round should be replaced with a new wheel.

Instructions for wheel replacement are listed below.

REMOVAL AND REPLACEMENT OF MOTOR/WHEEL ASSEMBLY (DIAGRAM N)

Disconnect power supply to the SideShot and heating equipment when servicing the SideShot. Failure to do so may result in per-

sonal injury and/or equipment damage.

1. Remove electrical box cover.

2. Disconnect the two motor leads from the terminal strip.

3. Remove motor bracket screw from electrical box.

4. Holding the motor, apply firm pressure towards the plenum of the SideShot and remove the six motor mount nuts. Note: Hold

the assembly firmly; failure to do so could damage internal parts.

5. Slide motor/wheel assembly from Plenum. Grasp only the motor casing; do not damage wheel, shaft or other components on

Plenum. Do not rest assembly on wheel.

WHEEL REPLACEMENT (DIAGRAM N)

1. Loosen set screw from wheel hub by using a 5/32” allen wrench.

2. Twist wheel to loosen and pull off of motor shaft. Do not pull too hard; wheel may bend. Wheels “fused” to shaft may require

penetrating oil and/or a wheel puller to facilitate removal.

3. Slide new wheel on to flat of shaft and firmly tighten set screw.

MOTOR OILING

The SideShot motor is permanently lubricated and requires no oiling.

21

DIAGRAM N

MAINTENANCE