420 plus enclosure reassembly, 420he enclosure reassembly, Analog output calibration – Rice Lake SURVIVOR 420 Plus/420HE Analog Output Card Installation User Manual

Page 2: Enter setup mode and go to the, Menu (see figure 4). • set

2

420 Plus/420HE

Analog Output Card Installation Instructions

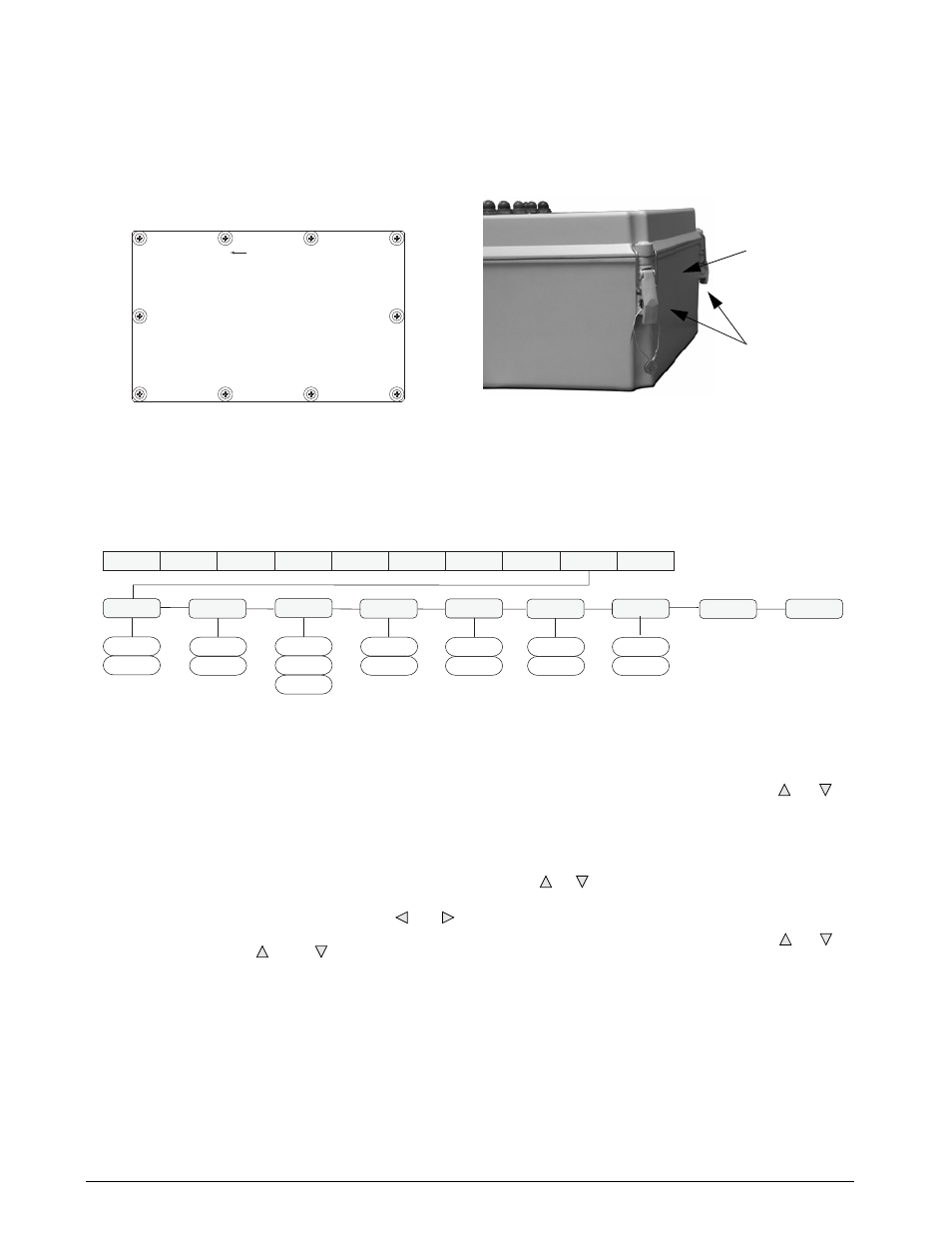

420 Plus Enclosure Reassembly

Once cabling is complete, position the backplate over

the enclosure and reinstall the backplate screws. Use

the torque pattern shown in Figure 2 to prevent

distorting the backplate gasket. Torque screws to 15

in-lb (1.7 N-m).

Figure 2.

420 Plus Backplate Torque Pattern

420HE Enclosure Reassembly

Once cabling is complete, close the front cover of the

indicator and hook the draw latches.

Figure 3.

420HE Enclosure Assembly

Analog Output Calibration

The following calibration procedure requires a multimeter to measure voltage or current output from the analog

output module. No test weights are required for calibration.

NOTE:

The analog output must be calibrated after the indicator itself has been configured and calibrated.

Figure 4. Analog Output Menu

1. Enter setup mode and go to the

ALGOUT

menu

(see Figure 4).

•

Set

OFFSET

to 0% for 0–10 V output, 20%

for 4–20 mA output

•

Set

MIN

to lowest weight value to be

tracked by the analog output

•

Set

MAX

to highest weight value to be

tracked by the analog output

To enter

MIN

and

MAX

values, use the and

keys to select the digit; use the numeric

keypad or the and to increment or

decrement the value.

2. Connect multimeter to analog output:

•

For voltage output, connect voltmeter

leads to pins three and four

•

For current output, connect ammeter

leads to pins one and two

3. Adjust zero calibration: Scroll to the

TWZERO

parameter. Check voltage or current reading

on multimeter. Press and hold or to

adjust the zero value up or down.

4. Adjust span calibration: Scroll to the

TWSPAN parameter. Ch eck voltag e or

current reading on multimeter. Press and hold

or to adjust the span value up or down.

5. Final zero calibration: Return to the

TWZERO

parameter and verify that the zero calibration

has not drifted. Press and hold or to

re-adjust the zero value as required.

6. Return to normal mode. Analog output

function can be verified using test weights.

1

6

9

4

2

5

7

10

Torque Pattern

8

3

D r a w

Latches

Top of

Indicator

XXXXXXX

XXXXXXX

ALGOUT

DIGIN

SETPNT

XXXXXXX

PROGRM

PFORMT

SERIAL

CALIBR

XXXXXXX

CONFIG

FORMAT

SOURCE

GROSS

0%

20%

OFFSET

ERRACT

FULLSC

HOLD

000000

number

MIN

10000

number

MAX

TWZERO

NET

TWSPAN

ZEROSC

VERS

MINNEG

OFF

ON

MAXNEG

OFF

ON