0 service information, 1 troubleshooting, 2 load cell replacement – Rice Lake RoughDeck FXB Flexure Lever Floor Scale User Manual

Page 17: Service information, 1 troubleshooting 6.2 load cell replacement

Service Information

13

6.0

Service Information

The following sections describe various troubleshooting and replacement parts information.

6.1

Troubleshooting

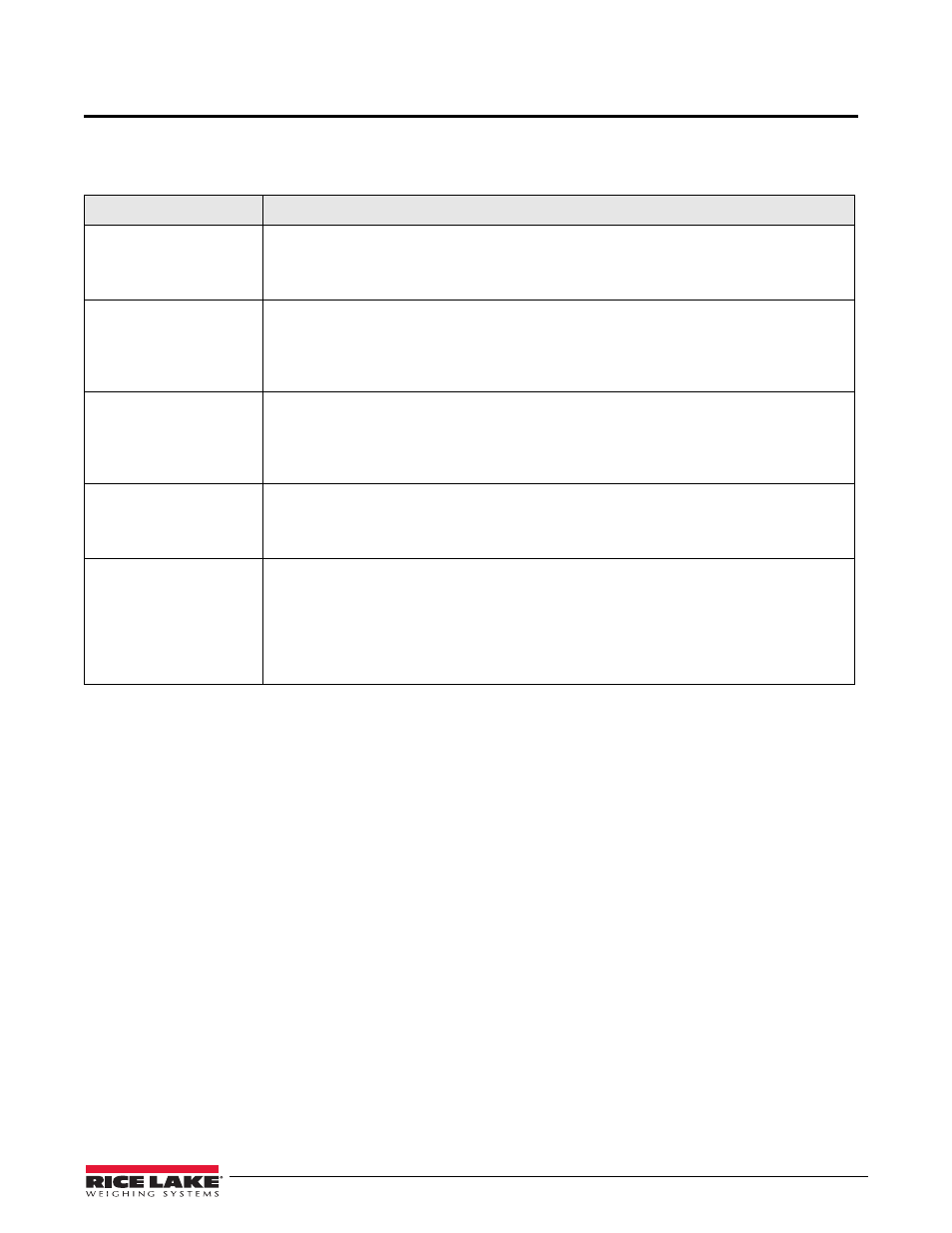

Table 6-1. Troubleshooting Table

Problem

Probable Causes

Shift Error

Center of flexure is offset from the center line

Corners are not shimmed tightly to the floor

Nose-iron on power lever too high or too low

Pivot heads need shimming

Erratic Readings

Bent flexures or cable assembly

Center leveling bolts not down far enough, or down too low

Corners are not shimmed tightly to the floor

Ground shield not connected to cannon plug or meter shield

Loose connection in the junction box

Non-linear Weight Reading

Center flexure is offset from the center line

Damage to the load cell

Misaligned flexure or cable assembly

Nose-iron on power lever too high or too low

Pivot heads need shimming

Corner Error

Corners are not shimmed tightly to the floor

Loose gripper

Misaligned flexure or cable assembly

Pivot heads need shimming

Zero Change

Corners not shimmed tightly to the floor

Damaged load cell

Live assembly touching the dead assembly

Loose gripper

Misaligned flexure or cable assembly

Shipping block has not been removed during unpacking

Obstruction under the load bridge (probably at the corner)

6.2

Load Cell Replacement

Replacement load cells can be ordered from Rice Lake Weighing Systems according to the table in Section 6.3. To

replace a load cell in an FXB follow the steps listed below.

1. Remove the deck assembly.

2. Loosen the bottom locking nut (see Figure 3-1 on page 7).

3. Remove the signal cable access hole cover plate. Pull wire rope from the plate and pass it through base.

4. Remove bottom lock nut from wire rope and back off upper lock nut. Using a hex allen wrench on the

flathead bolt, and an adjustable wrench to hold the load cell body, remove the load cell.

5. Remove the wire rope from the defective load cell and screw it into the new load cell to approximate

position it was in the old cell.

6. Insert the wire rope into the nose iron hold and turn the lower nut on loosely.

7. Hold flat washer in place, and screw flathead bolt into top of the load cell. Tighten the flathead bolt

securely using a hex allen wrench and adjustable wrench.

8. Tighten the lower lock nut on the wire rope against the nose iron (finger tightening only). Lock upper nut

down against the nose iron.

9. Pass the signal cable through the access hole and follow directions from Section 3.2

10. Replace the deck assembly and recalibrate according to Section 4.