Load cell wiring – Rice Lake RL9000TWM-HT Series User Manual

Page 7

3. Load Cell Wiring

1. Route the load cell cables so they will not be damaged or cut. Cable should not

be routed near heat sources greater than 150 °F. Do not shorten any load cell

cable. The load cell is temperature compensated with the supplied length of cable.

Cutting the cable will affect temperature compensation. Coil and protect excess

cable so it will not be mechanically damaged or be sitting in water.

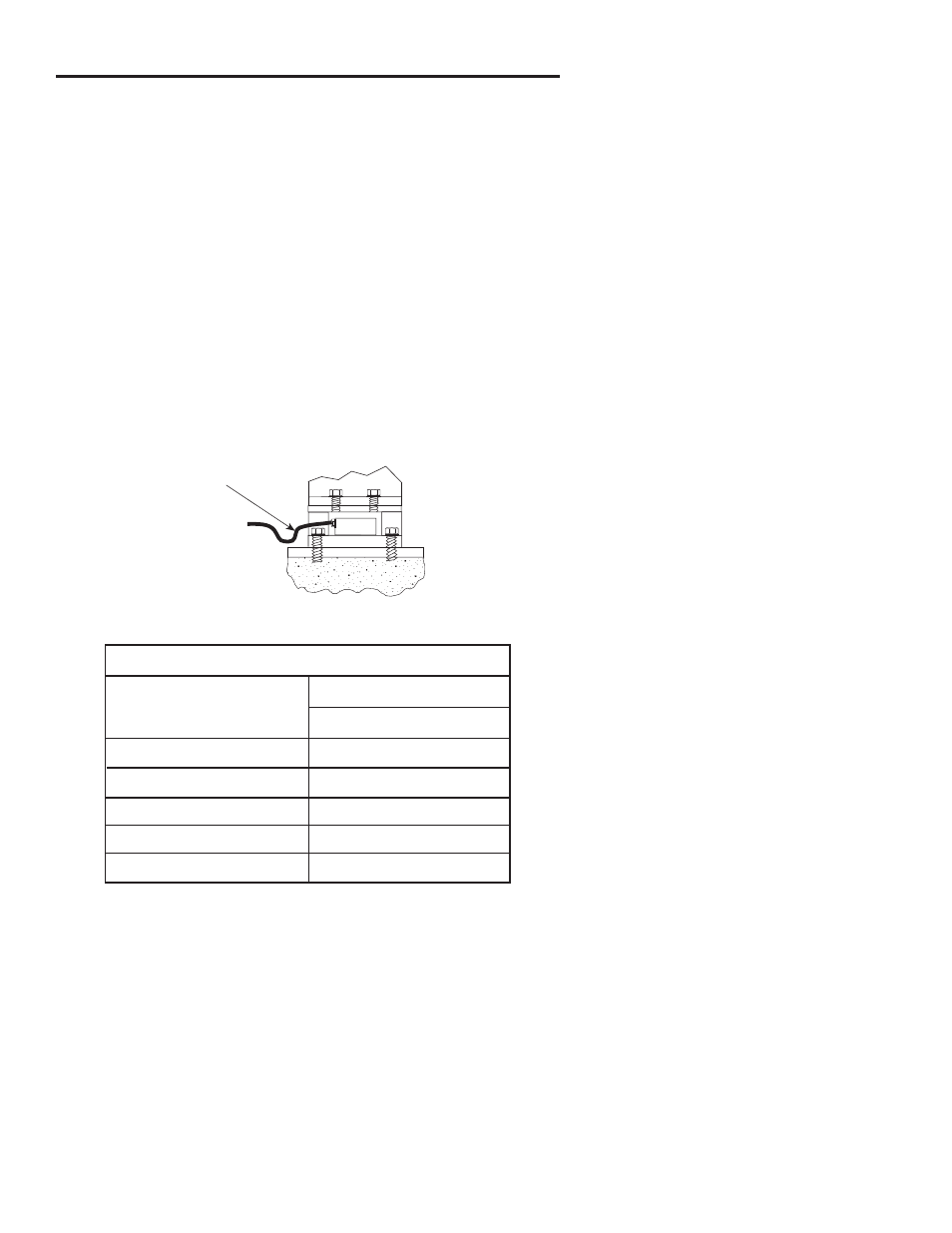

2. Provide a drip loop in all cables so that water or other liquids will not run directly

down the cables onto either the load cells or the junction box. Attach load cell

cable to the dead structure, not the vessel.

3. If conduit protection is necessary against mechanical or rodent damage to the load

cell cables, use fl exible conduit and conduit adapters at the load cells.

4. Connect cables for load cells to the summing board in the junction box according

to the guide shown below and the labels on the terminal strips of the junction box.

To verify the wiring scheme, see the certifi cation shipped with each load cell.

5. For better performance, use positive and negative remote sense lines if the wiring

running from the junction box to the indicator is longer than 25 feet.

Drip Loop

5

Load Cell Wire Colors

Wire Color

Function

Positive Reading

Green

Black

Red

White

Gray or Bare

+EXC

-EXC

-SIG

+SIG

Shield