0 maintenance, 1 lubrication, 1 round rail – Rice Lake Retail Scales - MajorSlice 350M User Manual

Page 16: Maintenance

12

MajorSlice 350M

4.0

Maintenance

Important

Important

Carriage tray and sharpener are calibrated to the unit and are not interchangeable with any other units.

Lift only at the bottom of the unit. Lifting at any other area may cause damage to the components and

will void the warranty.

4.1

Lubrication

Lubricate all moving parts and slide rails with USDA approved lubricants or pure mineral oil.

Important

Lubrication frequency of your slicer will always depend on the amount of operational usage. We

recommend lubrication on a weekly basis. If you find the carriage tray (#11) or the product grip slide

(#15) is not operating smoothly you may want to lubricate these points more frequently.

Use the lifting mechanism (#21) on model 350 to access the bottom of the slicer.

DO NOT lubricate machine with petroleum based, vegetable based or animal fat based products.

4.1.1

Round Rail

Lubricate with Food Grade Superlube (PN 151477), with PTFE (PN 77933) USDA H-1 food grade grease, white.

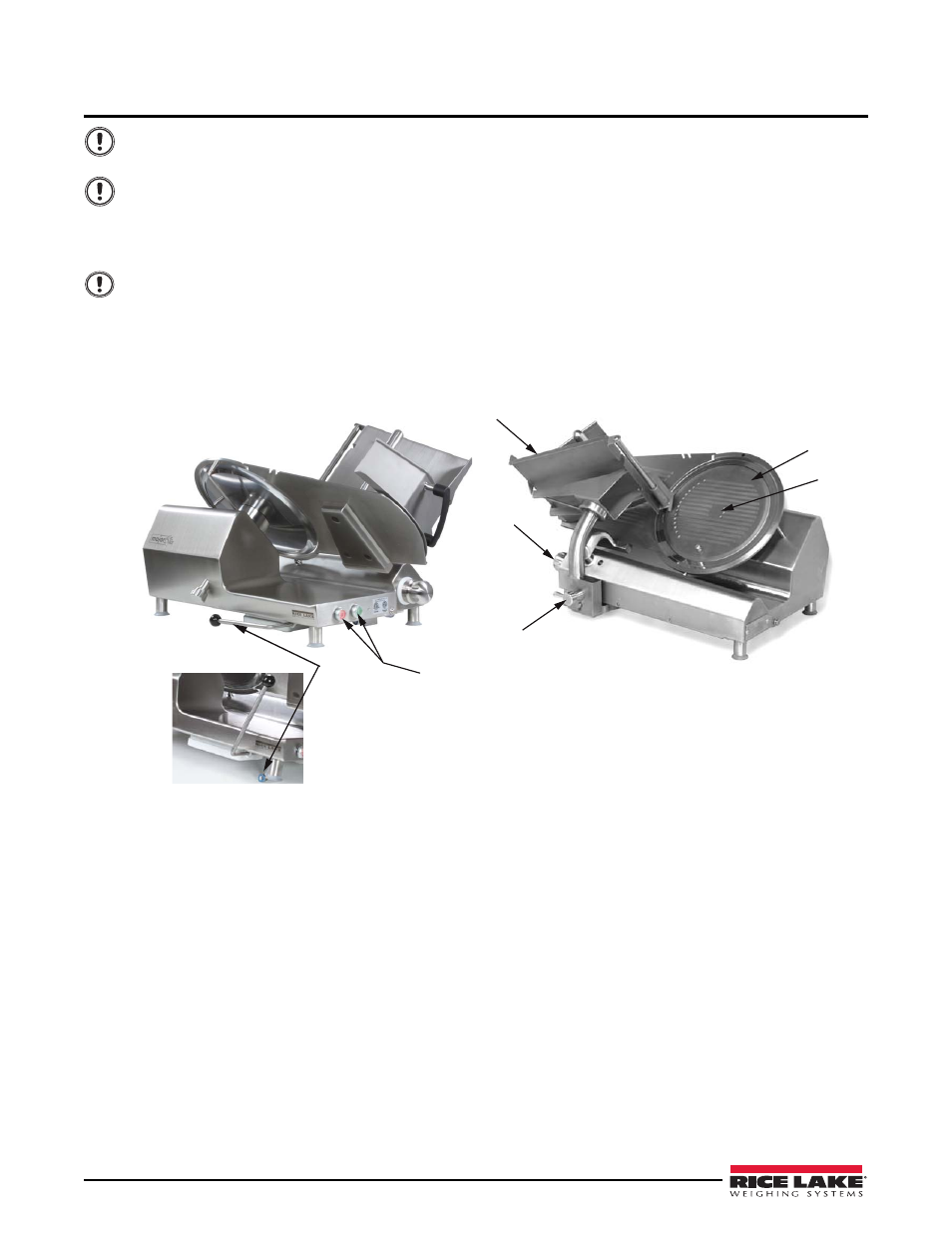

Back

4

3

11

19

18

6

Front

21

Figure 4-1. Slicer Lubrication

1. Power off the machine by turning off the (#3) power switch.

2. Unplug machine from power source.

3. Close the (#4) index control knob by turning clockwise.

4. Pull the (#11) carriage tray to the front and home position.

5. Turn the (#6) carriage tray release knob counter clockwise to release the carriage.

6. Remove the carriage tray (#11) by lifting straight up and clean separately.