Typical installation, Notice – FEBCO 876VST Master Series Configurable Design Double Check Detector Assemblies User Manual

Page 3

3

NOTICE

All assemblies are tested at the factory for

proper operation and leakage. If the valve

does not pass the field test, it is most

likely due to a fouled check valve. This is not

covered by the factory warranty. The valve

cover(s) must be removed and the check

seats inspected and cleaned. Any damage

or improper operation caused by pipeline

debris or improper installation/start-up is not

included in the factory warranty. In case of

a possible warranty claim, contact your local

supplier or FEBCO Representative. DO NOT

REMOVE THE VALVE ASSEMBLY FROM THE

PIPELINE.

8. The assembly must be protected from

freezing and excessive pressure increases.

Thermal expansion or water hammer can

cause pressure increases. These excessive

pressure situations must be eliminated to

protect the valve and system from possible

damage.

NOTICE

The flange gasket bolts for the gate valves

should be retightened during installation as

the bolts may have loosened due to storage

and shipping.

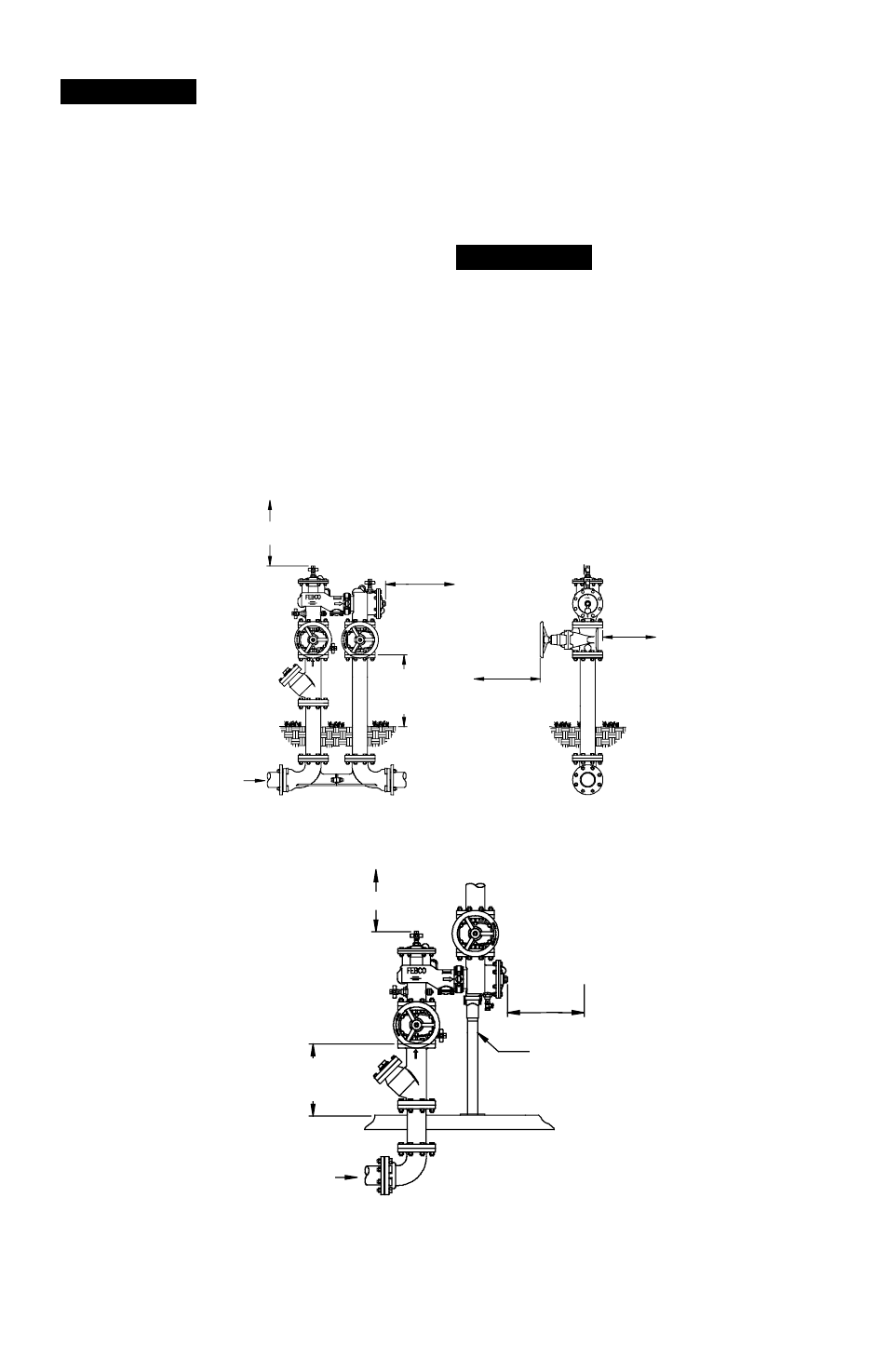

Typical Installation

18" Min. (450mm)

18" Min.

(450mm)

Refer to

Local Codes

18" Min.

(450mm)

6" Min.

(150mm)

FLOW

N-PATTERN INSTALLATION

FOR THE DC SERIES 870V/

LF870V & FOR THE DCDA

SERIES 876V/ LF876V/ 876VST

(Shown with Strainer)

Figure 2

18" Min. (450mm)

18" Min.

(450mm)

Pipe Support

(Furnished by Customer)

Refer to

Local Codes

FLOW

VERTICAL INSTALLATION FOR THE DC SERIES

870V/LF870V & FOR THE DCDA SERIES 876V/ LF876V/ 876VST

(Shown with Strainer)

Figure 1