Offset jack screw assembly, Butt hinge appl, Push/pull assembly – EFCO T300 Series User Manual

Page 9: Page 8

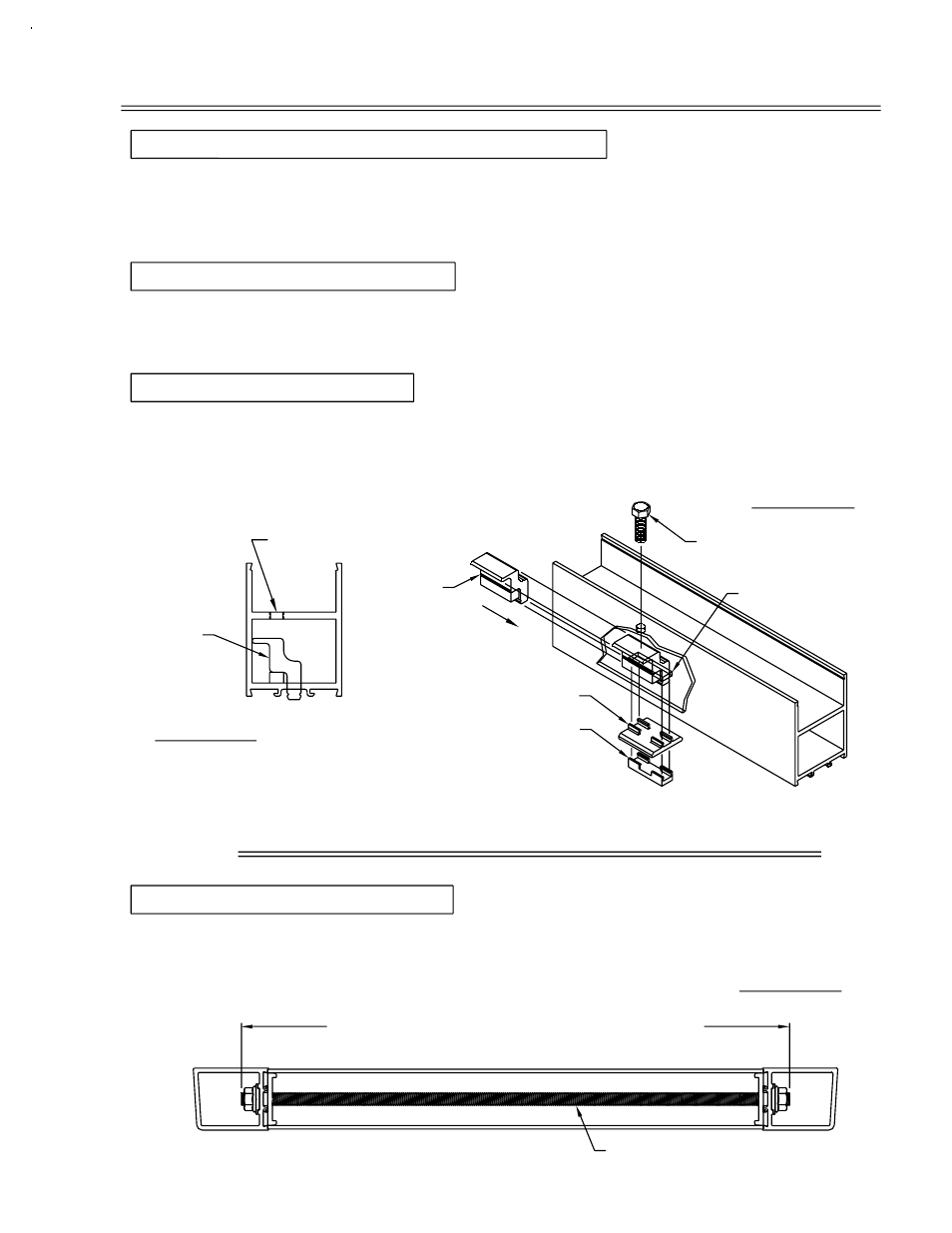

FIGURE #3

SECTION V: TIE ROD CUT LENGTH

STEP #4 TIE ROD CUT LENGTH

FIGURE #1

STEP #3 JACK SCREW CAPS

STEP #2 JACK SCREW INSERTION

FIGURE #2

STEP #1 OFFSET JACK SCREW BLOCK INSERTION

SECTION IV: OFFSET JACK SCREW ASSEMBLY

PAGE 8

SLOT IN TOP RAIL

CUT LENGTH = D.O.W. minus 2 3/4" T200

CUT LENGTH = D.O.W. minus 5 1/2" T300

#M120 OR #M151

Measure the tie rod (#M120 or #M151) as shown in Figure #3 and cut, if required, to the

formulas below.

Determine which door glazing is used. For 1/4" glass, use the 1/4" jack screw cap

(#HB18). For 1" glass, use the 1" jack screw cap (#HB19). Snap the correct jack screw

cap to the jack screw block. Use one cap per top rail. See Figure #2 below.

Insert one (1) jack screw (#IHP2/M103) per top rail. Tighten the screw enough to allow

the jack screw cap (#HB18 or #HB19) to be snapped to the jack screw block

(#K421/K432). See Figure #2.

Insert the offset jack screw block assembly (#K421/K432) through the end of the top rail

and down into the slot cut in the glazing side of the rail. Position the edge of the jack

screw assembly toward the side of the top rail with the hole prep for the jack screw.

See Figure #1.

ALIGN THIS EDGE

WITH HOLE PREP

#HB18 AT 1/4" GLASS

#HB19 AT 1" GLASS

#K421

#K432

OFFSET HOLE PREP

DPS/BB JULY 2000

#IHP2

#M103