Header prep for coc, Exterior, Page 15 – EFCO T300 Series User Manual

Page 16

STEP #21 LATCHING AND CLOSING SPEEDS

FIGURE #17

"C" valve

CLOSING SPEED

"L" valve

LATCHING SPEED

4"x 4 1/2" W/ 3/32" RECESS

OFFSET PIVOTED DOOR

SECTION XII: CLOSER ADJUSTMENTS

90

105

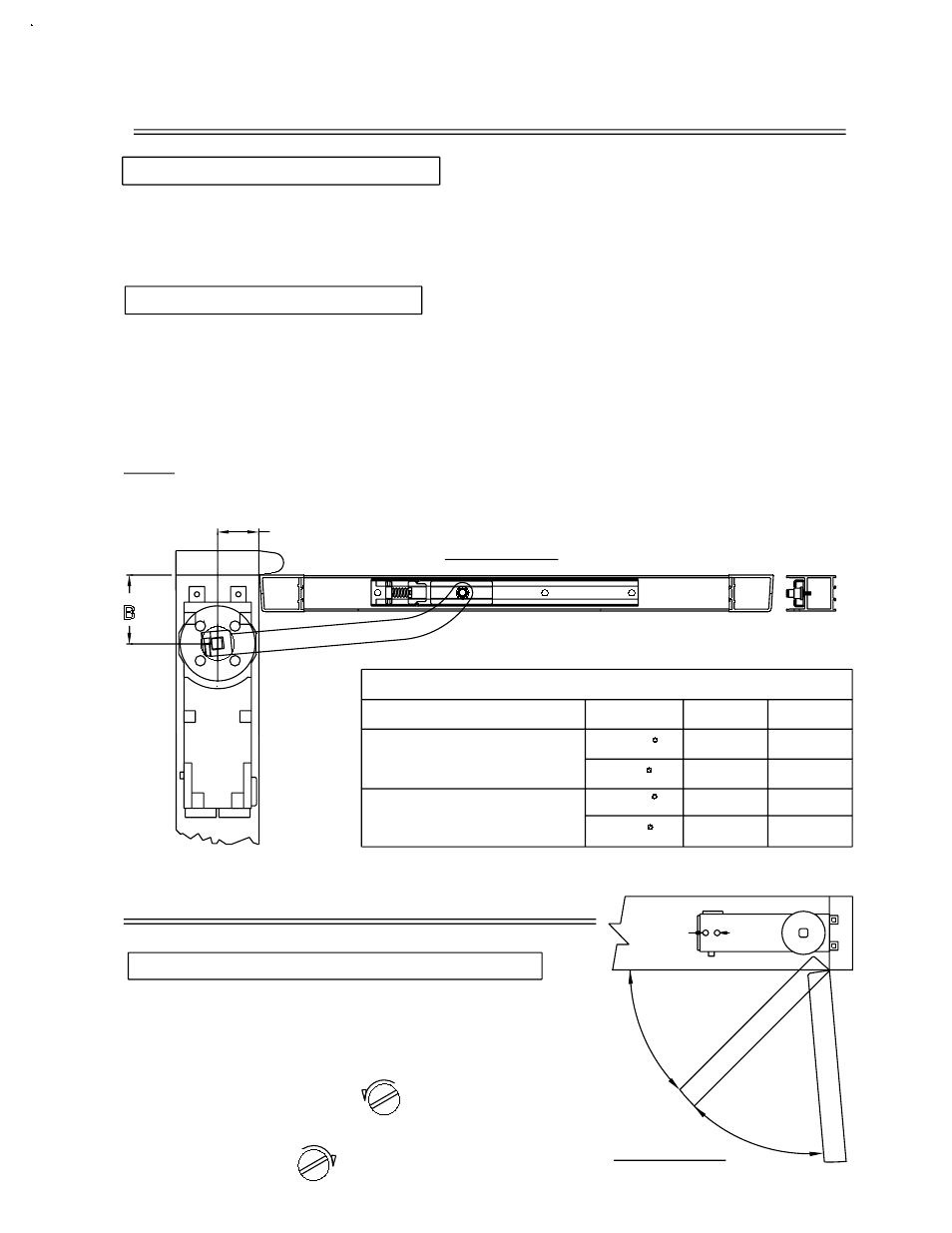

CHART FOR C.O.C. HEADER PREPARATIONS

90

105

BACKSTOP

BUTT HINGED DOOR

MINIMUM 4" HEADER

MINIMUM 4" HEADER

3/32" RECESSED DOOR

HINGING

2"

2 3/4"

2 3/4"

2"

"C"

"L"

DIM"B"

3 3/4"

2"

2"

DIM"A"

3"

FIGURE #16

105

90

STEP #20 C.O.C. INSTALLATION

STEP #19 HEADER PREPARATION

SECTION XI: HEADER PREPARATION FOR C.O.C.

PAGE 15

A

DPS/BB JULY 2000

A. The latch and closing speeds have been preset, but

may require further adjustment. See Figure #17.

B. The closing valve is preset to the minimum speed.

C. To increase latching and/or closing speed, turn the

valves counterclockwise.

D. To decrease latching and/or closing speed, turn the

valves clockwise.

1. Install the closer in the prepared header.

2. Install the slide in the slide channel with the end marked 90˚ toward the hinge edge of

the door, if the 90˚ backstop closer is used, or with the end marked 105˚ backstop closer.

3. Place the arm on the closer spindle and tighten the 1/4"-20 socket head screw

securely. Rotate the arm from center as if the door was open. Place the hole in the arm

over the pin in the slide and secure with the ’C’ clip.

NOTE: For other information on C.O.C.’s, contact EFCO’s Manufacturing Department.

For C.O.C. header preps, see chart below for dimensions based on application.

1. DIMENSION ’A’, face of jamb to center line of spindle must be maintained.

2. DIMENSION ’B’, pivot or hinge side of header to center line of spindle regardless of header

width. See Figure #16.