Push pull assembly, Page 11 – EFCO T300 Series User Manual

Page 12

(DOOR OPENING WIDTH) (1/2) - 3.438"

PAIRS

SINGLES

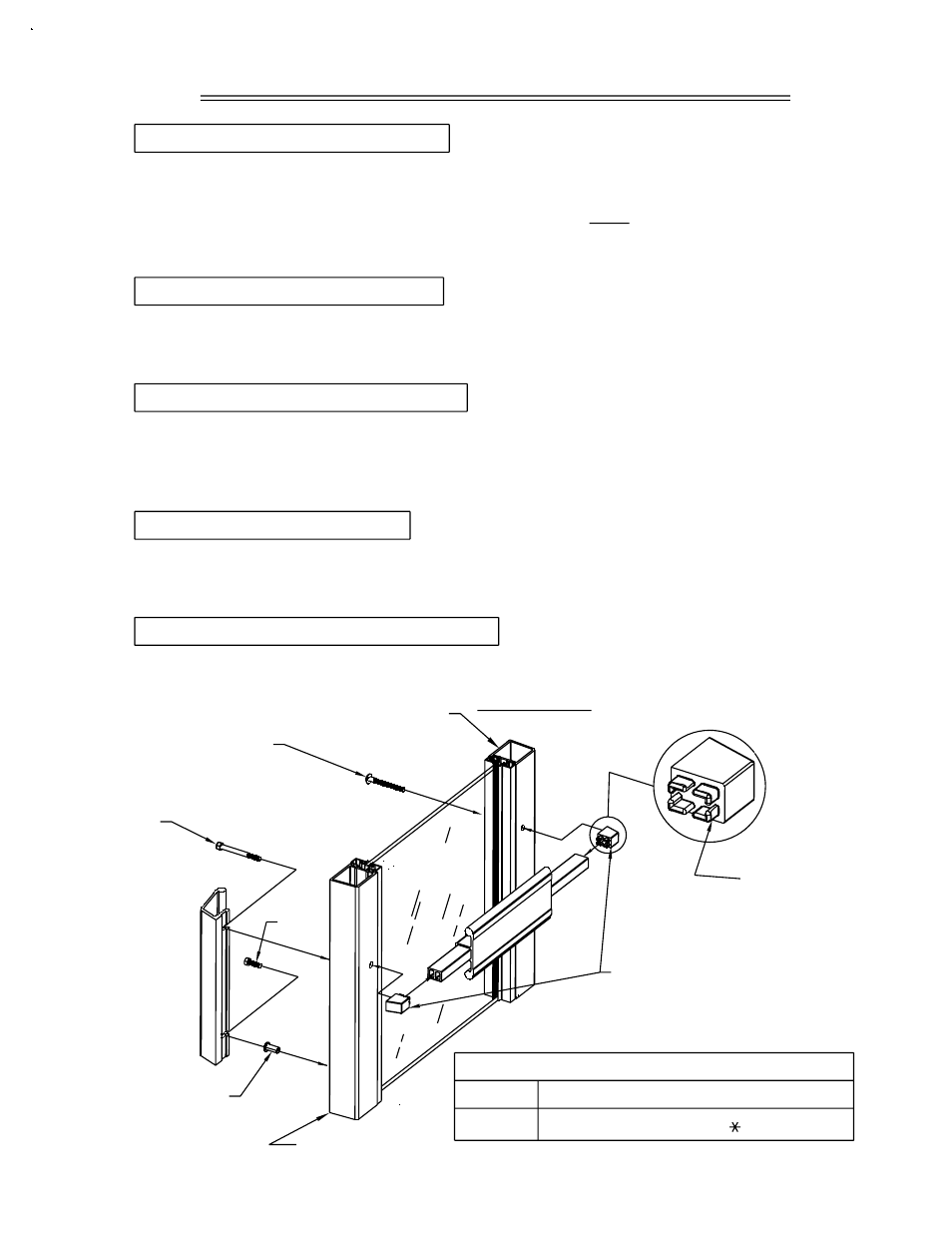

STEP #14 PULL HANDLE APPLICATION

FIGURE #10

STEP #11 PULL HANDLE BOLTS

STEP #13 LOCK STILE BOLT

STEP #12 PUSH BAR APPLICATION

(DOOR OPENING WIDTH) - 3.500"

PUSH BAR CUT LENGTH FORMULA

SECTION VIII: PUSH/PULL ASSEMBLY

STEP #10 PUSH BAR END CAPS

PAGE 11

#M105

1/4"-20 X 2 1/2

HX-MS 18-8

Continue holding the push bar to the door and align the hole on the hinge stile with the

hole in the mounting cap. Attach the hinge stile of the push bar with the 1/4"-20 x 2 1/4"

PL-TH-MS (M104) dress bolt shown in Figure #10.

DPS/BB JULY 2000

TWO PART EPOXY

APPLIED TO LEGS

OF END CAPS

#I107 1/4"-20

RIV NUT

LOCK STILE

Slide the pull handle under the hex head bolts at the lock stile and tighten.

#IHP2

#M104

1/4"-20 X 2 1/4

PL-TH-MS 18-8

Hinge/Pivot Stile

HB20/HB21 PUSH

BAR END CAPS

Hold the push bar to the door and start the hex head bolt (#M105) at the lock stile as

shown in Figure #10. After installing the hex head bolts (#IHP2 and #M105), leave hex

head bolts loose, with a minimum 5/16" gap. This will allow the pull handle to slide under

the hex head bolt.

Start one (1) 1/4"-20 x 3/4" (#IHP2) hex head bolt into the factory installed riv nut located

in the lock stile. Insert one (1) 1/4"-20 x 2 1/2" (#M105) hex head bolt into the predrilled

hole in the lock stile.

If required, cut the push bar to length. The push bar must be cut from the hinge end.

Consult the chart below for the correct cut length formula. Insert the push bar end caps

into the ends of the push bar as shown in Figure #10. Note: To ensure a tight fit, EFCO

recommends applying a thin coat of two part epoxy to the legs of the end caps prior to

being inserted into the push bar. See Figure #10.