Perimeter seal later – EFCO 5800 Series User Manual

Page 8

perimeter seal later.

THE BACKER

CUT AND FOLD

ROD 90 DEG.

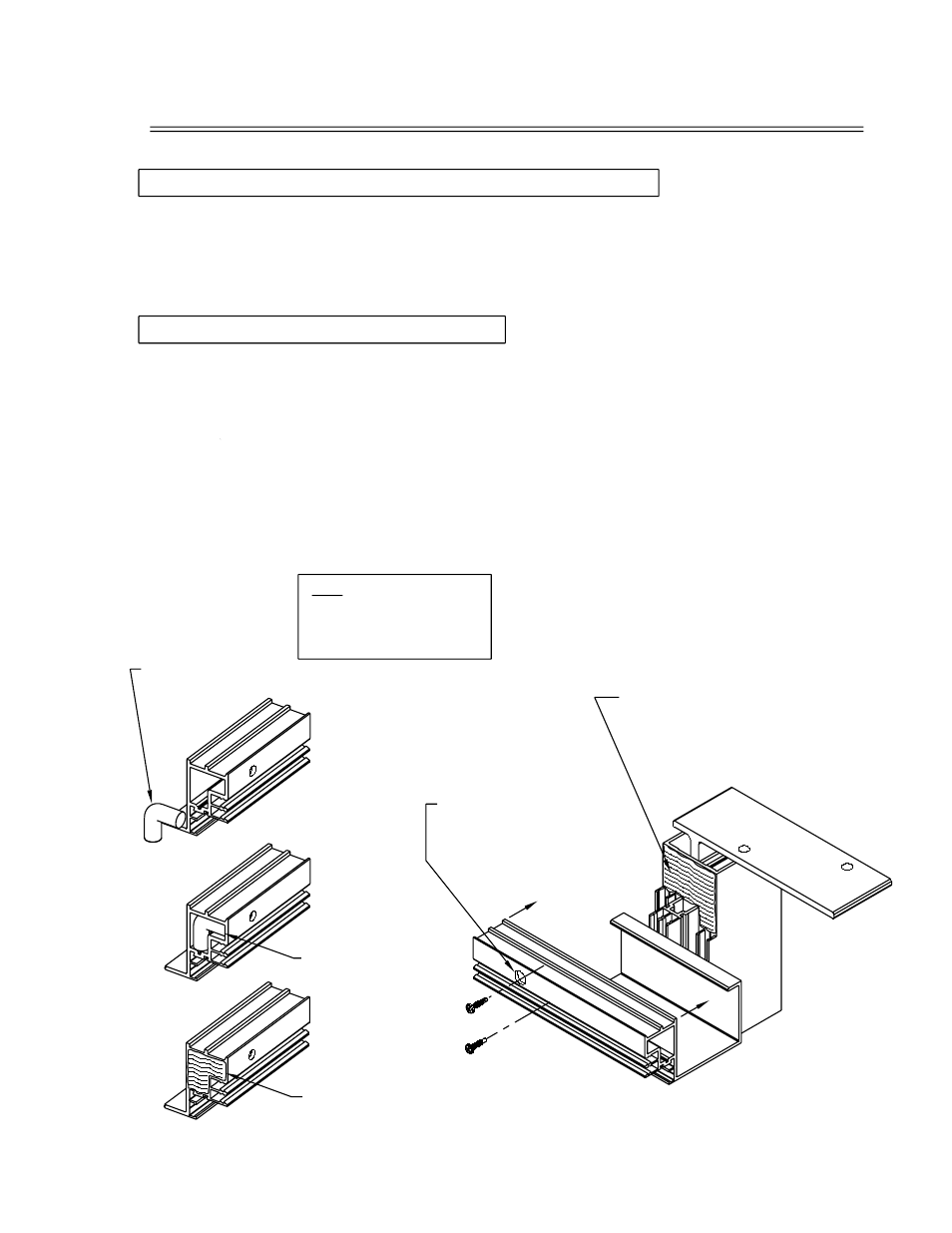

STEP #1 PLUG ENDS OF PERIMETER HORIZONTALS

spacing to avoid dimensional build-up across the opening.

center line dimension at each horizontal installation before and after fastening

the predrilled holes in the ends of each horizontal. Confirm the mullion

appropriate horizontal member to the vertical mullion at the notch with (2)

the horizontal into place. Verify the mullion locations at every fifth mullion

Stalgard , #10-16 x 3/4", PL-PH-SMS, Tek/2, self drilling fasteners through

to the factory notched vertical mullion, at the horizontal locations. Attach the

Clean all mating surfaces and apply a thin film of specified sealant

silicone to create an end plug. The end plug will act as a back-up for the

Prior to horizontal attachment, insert a 2 1/2" piece of backer rod folded to

SECTION III: HORIZONTAL FRAME INSTALLATION

STEP #2 PERIMETER HORIZONTALS

90 degree into the jamb end of the head and sill horizontals. Seal the ends with

SEAL OVER THE END

AND TOOL FLUSH WITH

THE EXTRUSION.

ROD 1/4" INSIDE

INSERT THE BACKER

THE EDGE OF THE

EXTRUSION.

ONCE THE HORIZONTALS

ARE INSTALLED, INSERT

BACKER ROD INTO THE

HOLE AND SEAL THE

HOLE FLUSH WITH

any area, clean the

alcohol.

surface with denatured

SILICONE.

Note: Prior to sealing

R

APPLY A THIN LAYER OF

MULLION. APPLY SEALANT TO

ENTIRE FACE OF THE COPED

SPECIFIED SEALANT TO THE

THE PERIMETER HEAD AND

SILL HORIZONTAL MEMBERS ONLY.

THE ENDS OF THE MULLION AT

PAGE 6

7/2003