Connecting the motor – Craftsman 113.2472T0 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

14. Belt tensioning is done by tightening the wing

nut which pulls the motor down. The motor

slides on the three (3) spacers and is locked in

place by the flanged lock nut at the threaded

stud.

Belt tension is important. Over tensioning may

cause vibration while too little tension may allow

the belt to slip under heavy loads.

TIGHTEN FLANGE

NUT AFTER TENSIONING

BELTWITH WING NUT

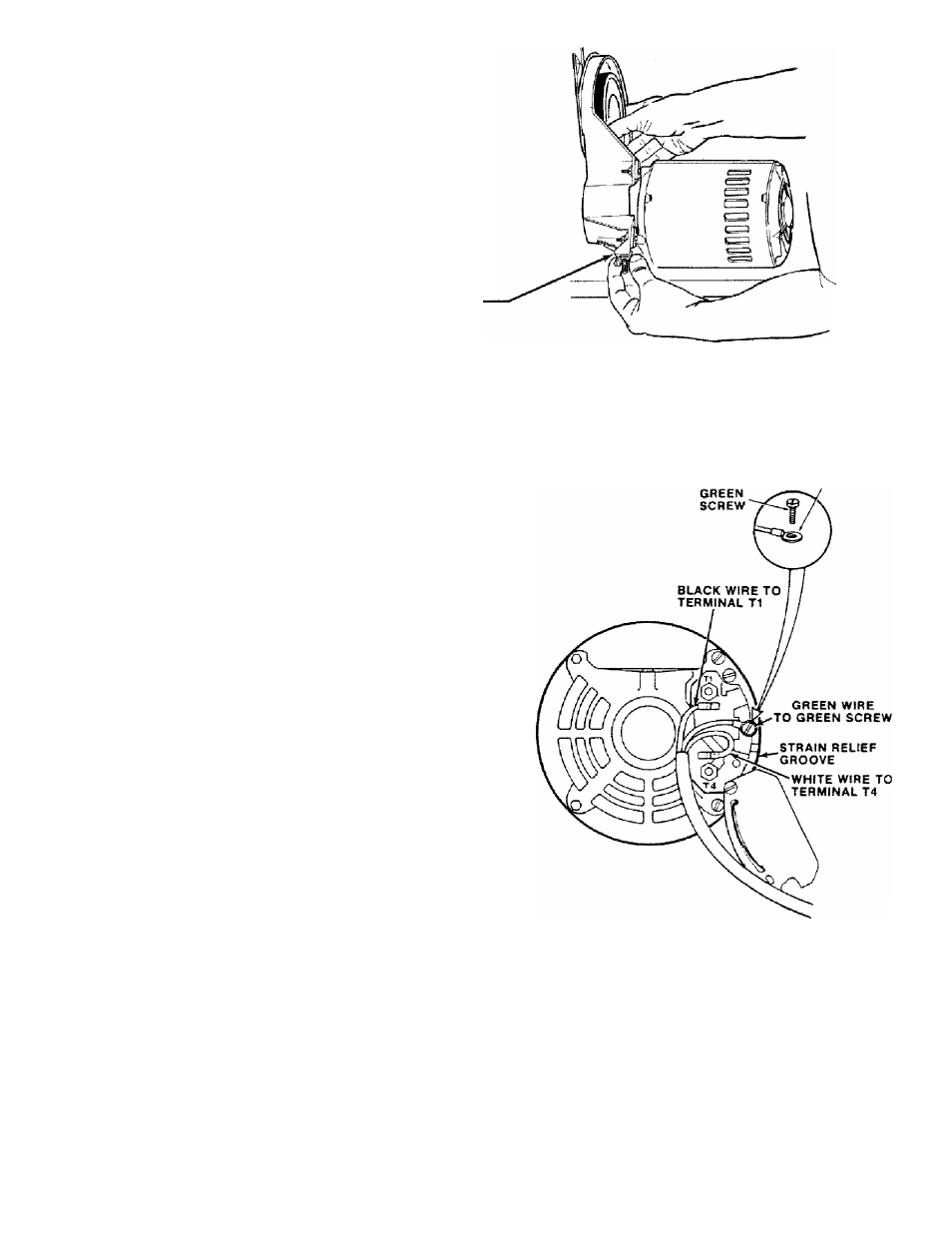

CONNECTING THE MOTOR

1. Next, the motor cord needs to be wired into the

motor. Coming from the underside of the table

will be a cord with a black, white and green wire.

This is the motor cord.

WARNING: FOR YOUR OWN SAFETY, NEVER

PLUG

THE

SAW

IN

UNTIL

ALL

ASSEMBLY

STEPS ARE COMPLETED.

2. Loosen the two screws holding the connector

box cover on the back side of the motor. Swing

the cover open.

3. Install the green ground wire by removing the

green grounding screw and inserting it through

the round metal terminal on the green ground

wire of the motor cord. Reinstall the green screw

into the hole from which it was removed and

tighten securely.

WARNING:

TO

AVOID

ELECTROCUTION,

NEVER

CONNECT

ANYTHING

BUT

THE

GROUND

WIRE

(COLORED

GREEN)

TO

THE

GREEN SCREW.

4. Insert terminal end of WHITE wire on spade

terminal marked T4 on the motor. Push terminal

firmly until seated.

5. Insert terminal end of BLACK wire on spade

terminal marked T1 on the motor. Push terminal

firmly until seated.

6. Close motor connector box being sure that

power cord is seated in the largest strain relief

groove and tighten box cover screws.

7. DO NOT plug in power cord.

TERMINAL

IS