Taylor-Wharton EasyCarb User Manual

Page 6

6

gas flow.

3.

Fabricate two lengths of ½ in. (12.7 mm) ODT copper or ½ in. (12.7 mm) I. D. nylon

tubing.

4.

Drill a small pilot hole through the outer wall surface first to confirm that there are

no utility lines in the location selected, then enlarge the opening to a 2 ½ in. (64

mm) opening.

5.

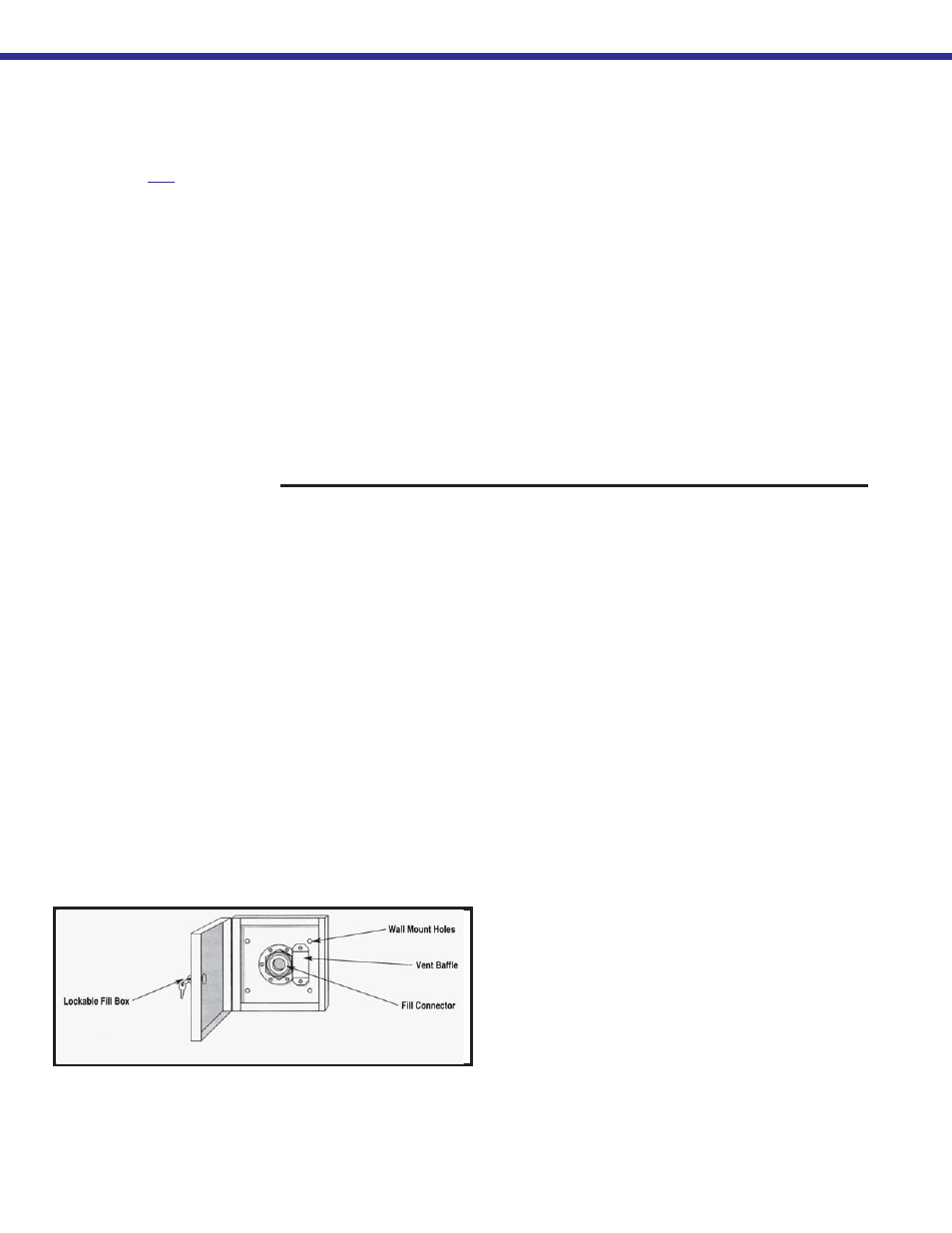

The fill box contains copper tube sections long enough to pass through the wall.

The fill section is already coupled but you must attach the vent section to the

bracket beneath the fill coupling using the strap clamp

and screws provided.

6. Pass the fill line through the wall, and mark for

cutting to length. Pull the fill box back off the wall. Cut

fill line to length, then cut vent line to same length, and

secure with screw to bracket in back of fill box.

7. After cutting the fill box tube sections to length,

install the box. Level the box, then mark four wall

anchor holes and drill; secure with appropriate anchor-

ing hardware. Weather seal between the box and the

building exterior is recommended.

Cylinder Handling

The easycarb™ cylinder can weigh upwards of 375 lb. (170 kg), but can easily be

moved by using a properly designed hand truck. A special Harper cylinder truck

(Model ULG 650A) is recommended. The container can also be lifted and moved

with a crane or hoist by attaching a sling to the holes, provided in the ring supports on

the top of the cylinder. Do not attach lift hooks to ring. Except for minor tipping on

the hand truck, the container must be kept upright at all times, and should not be

moved or transported full.

Installation Procedure

See page 12 for Component Identification.

1.

Determine the location for the fill box on the outside wall.

SPECIAL NOTICE

Be sure and take the height of the fill box into consideration. Do not install box at

face height (approx.5 ½ ft./1.7 m). This can be dangerous during delivery. The

suggested height of mounting is approx. 3 to 4 ft. (.9 to 1.2m) above the ground.

WARNING:

Be sure there are no hidden utility lines in the location selected for mounting.

Consult the building plans, or make a test opening to confirm the wall is clear

of hidden hazards before drilling.

2.

Measure the distance from the container to location where the fill box will be mounted to

determine the length of fill and vent line material required. Be careful to allow for all

routing and for thickness of the outside wall. Avoid sharp bends that may restrict liquid or

CAUTION:

If lifting by crane or hoist,

insert hooks in both lifting lug

openings on the cylinder ring.

Failure to do so could result

in container damage or

personal injury.

CAUTION:

If the container is installed in an

elevated location, it must be on

a well constructed platform that

will support more than 975 lb.

(422 kg.) When installed this

way, the easycarb™ must be

anchored to the wall from a

point on the top of the

container.

Note:

Nut and ferrule for vent line

and liquid connection are

attached to the plumbing to

prevent loss during shipment.

Fill Station